A hybrid pdc drill bit for cutting and breaking rock

A hybrid, drill bit technology, used in drill bits, drilling tools, earth-moving drilling, etc., can solve the problems of inconvenient use, inability to impact crushing, poor drilling ability, etc., to ensure drilling quality, high degree of automation, and expand cutting. effect of radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

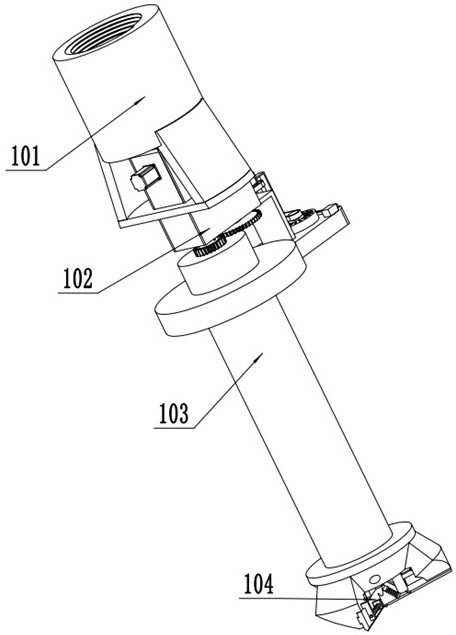

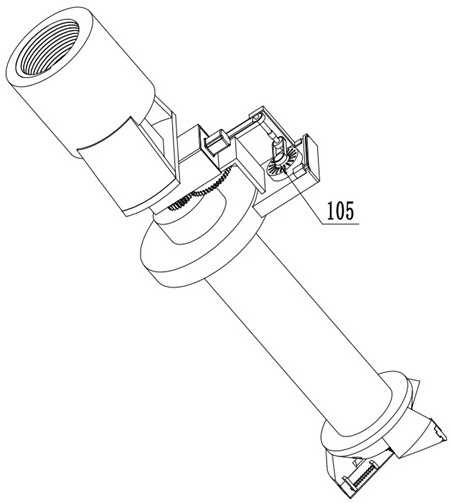

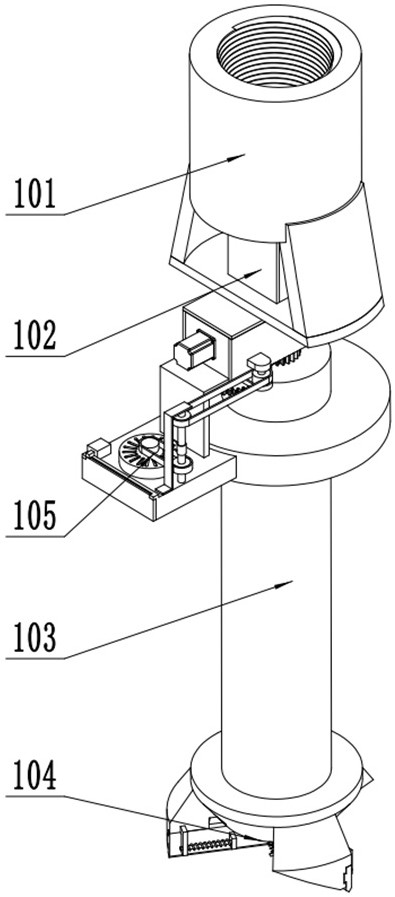

[0031] Example: such as figure 1 , figure 2 , Image 6As shown, a cutting and rock-breaking hybrid PDC drill bit includes an installation joint 101, a power assembly 102, a transmission assembly 103, a cutting assembly 104, and a dust assembly 105. The first end of the installation joint 101 is fixedly installed on the power assembly 102. The second end of the joint 101 is provided with an internal thread for installing and fixing the cutting rock-breaking hybrid PDC drill bit. The dust outlet assembly 105 is fixedly installed on the power assembly 102. At the same time, the dust outlet assembly 105 is fixedly connected with the round table 123. There is a transmission assembly 103, the first end of the transmission assembly 103 is fixedly connected with the power assembly 102, the second end of the transmission assembly 103 is fixedly equipped with a cutting assembly 104, the dust outlet assembly 105 communicates with the transmission assembly 103 through the round table 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com