Aluminum grating assembly type ceiling structure for airport and construction process thereof

A prefabricated, aluminum grille technology, applied in the direction of ceilings, building components, building structures, etc., can solve the problems of lower passenger rest quality, achieve the effects of improving closing efficiency, reducing friction, and improving rotational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

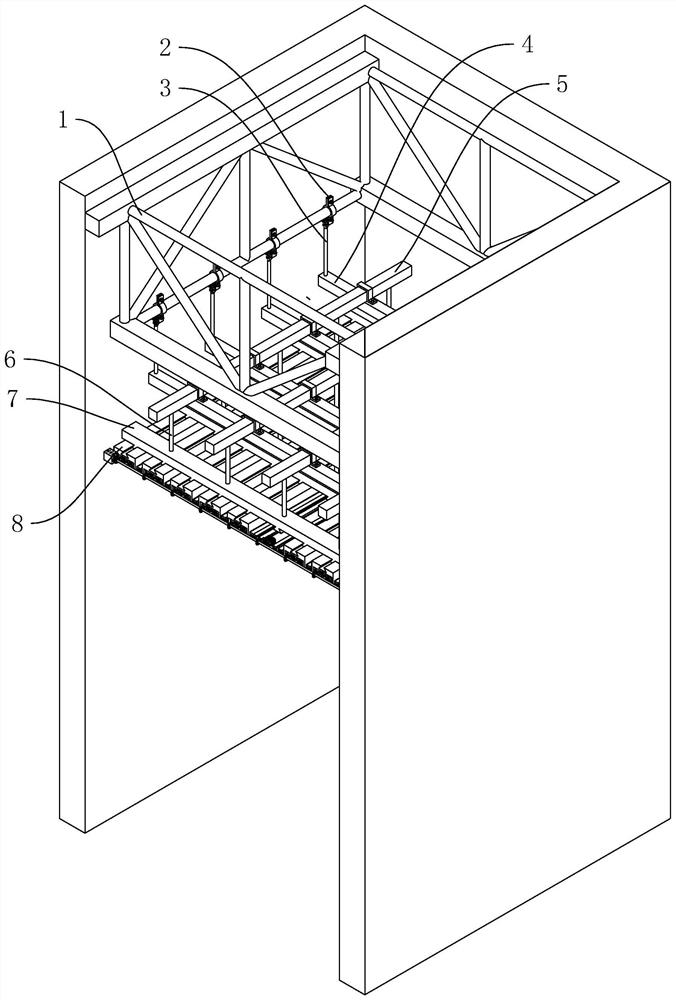

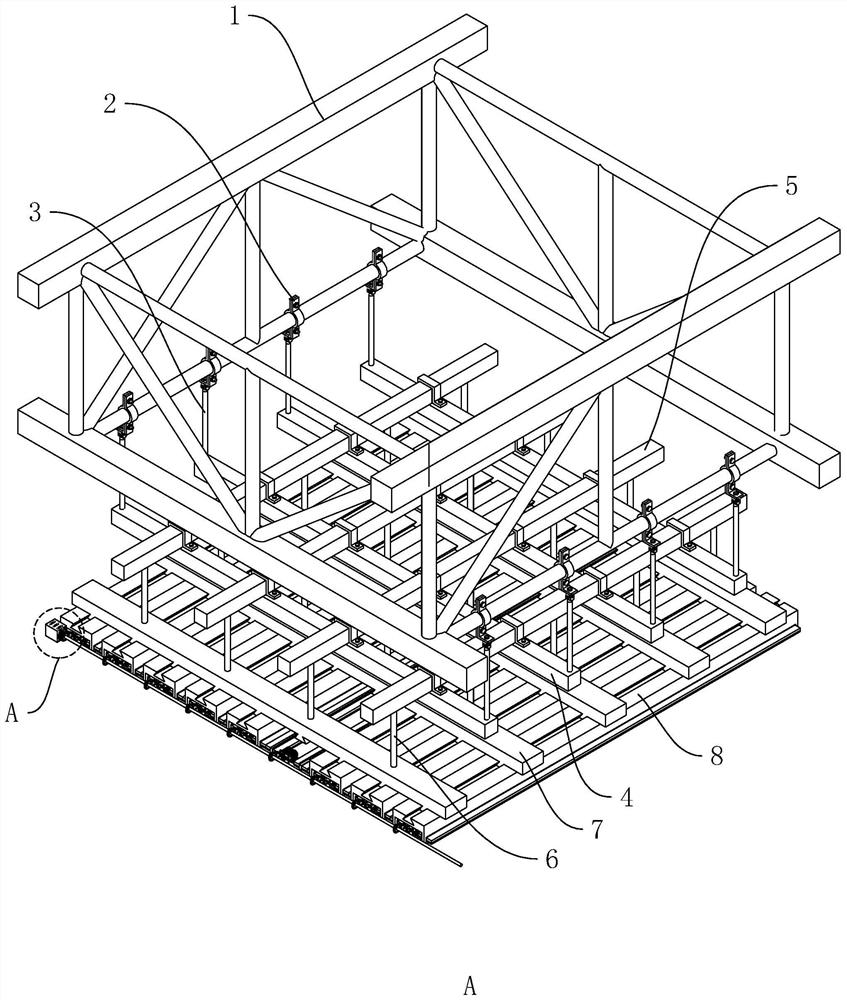

[0043] The embodiment of this application discloses an aluminum grid assembled ceiling structure for airports, refer to figure 1 , including steel frame 1, clamp 2, first suspender 3, main keel 4, auxiliary keel 5, second suspender 6, professional keel 7 and aluminum plate 8, and steel frame 1 is fixedly connected to the inner wall of the wall along the horizontal direction , the hoop 2 is clamped and fixed with the steel frame 1 through a threaded connection, the first suspender 3 is fixedly connected with the side of the hoop 2 away from the steel frame 1 along the vertical direction, and the main keel 4 is arranged on the first suspender along the horizontal direction 3 below, and the horizontal ends of the main keel 4 are respectively fixedly connected with the end of the first suspender 3 away from the clamp 2, multiple main keels 4 are arranged in parallel, and the auxiliary keel 5 is fixed on the side of the main keel 4 away from the ground through a few characters , an...

Embodiment 2

[0053] A construction technique for an aluminum grid assembled ceiling for an airport, comprising the following steps:

[0054] S1. Install the aluminum grille assembled ceiling according to the specifications;

[0055] S2. Open a storage hole 9 in the aluminum plate 8, place two noise reduction plates 11 in the storage hole 9, and open a transmission hole 10 connected to the storage hole 9 on the opposite side of the two adjacent aluminum plates 8, and the noise reduction plate 11 is slidingly connected with the transmission hole 10;

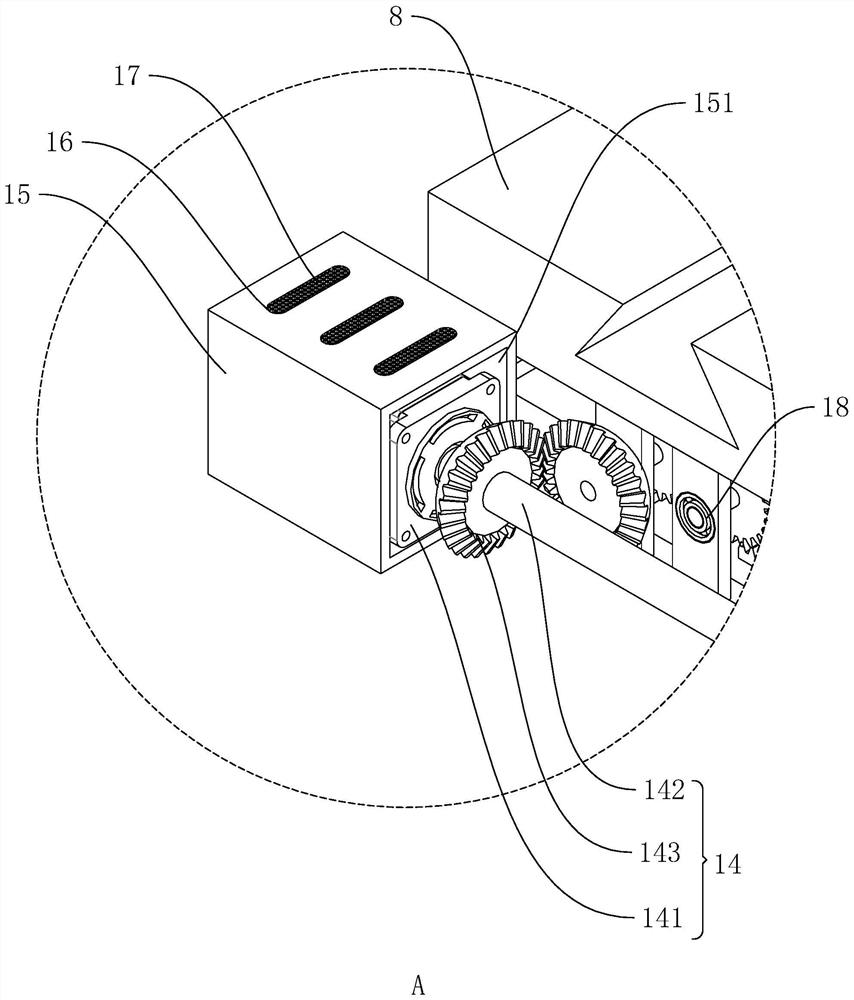

[0056] S3, a vertical fixed rod 121 is fixed inside the storage hole 9, and the fixed rod 121 is arranged symmetrically along the center line of the aluminum plate 8, and a horizontal rotation hole 13 is provided on the surface of the fixed rod 121, and the primary rotation rod 126 is connected to the secondary Rotationally connected in the rotating hole 13, the main gear 124 is fixed on one end of the primary rotating rod 126, the secondary g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com