Heat preservation and decoration integrated template and wall structure

A technology of thermal insulation board and decorative board, which is applied in the field of thermal insulation and decoration integrated formwork and wall structure, which can solve the problems of difficult construction, low efficiency, irregularities, etc., and achieve the effect of satisfying the safety of anchoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

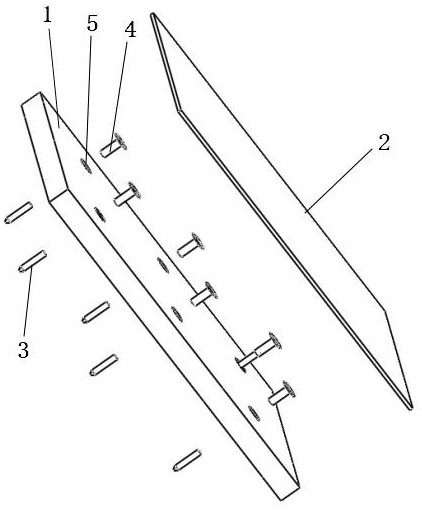

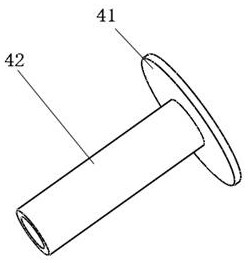

[0034] Such as Figure 1 to Figure 7 As shown, this specific embodiment provides an integrated formwork for thermal insulation and decoration, including a facing layer 7, a protective layer 6, a thermal insulation board 1, a lining layer 8, a connection cap 4 and a connector 3, and the outer surface of the thermal insulation board 1 is set Groove 5 is arranged, and installation through hole is arranged in groove 5, and connection cap 4 is installed in the installation through hole, and connection cap 4 comprises column body portion 42 and column head portion 41, and column body portion 42 is positioned at installation through hole, and column The head 41 is located in the groove 5, the outer diameter of the column head 41 is larger than the column body 42, the column head 41 is blocked in the groove 5, and the column head 41 is lower than the outer surface of the insulation board 1 or connected to the insulation board 1 The outer surface of the connecting cap is flush, and the...

specific Embodiment approach 2

[0038] Such as Figure 8 As shown, this specific embodiment provides a wall structure, including the base wall 100 and the thermal insulation and decoration integrated template in Embodiment 1, the thermal insulation board 1 is located on the outside of the base wall 100, and one end of the connector 3 is connected to the The connecting cap 4 is detachably connected, and the other end of the connecting head 3 extends into the primary wall 100 . By prefabricating the connection cap 4 in the insulation board 1, and not protruding from the inner and outer sides of the insulation board 1, it is convenient for the storage and transportation of the insulation board 1 and the formwork made, and the factory prefabrication is realized, and the connection cap is directly installed in the wall construction process. The connector 3 is installed on the 4, which saves time and labor. The connector 3 is poured into the concrete wall, which not only enhances the reliability of the connection,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com