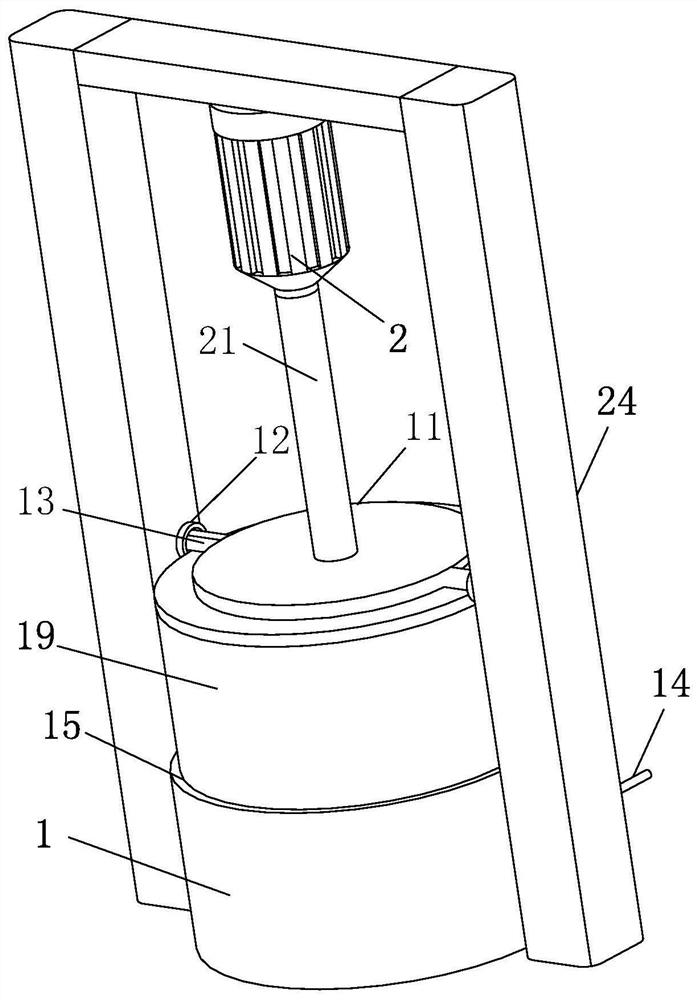

Wine brewing production line

A technology of a production line and cooking barrel, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of increasing the equipment footprint of the brewing production line, the large number of brewing production equipment, and the high cost of brewing equipment, so as to shorten the cooling time, improve the cooking efficiency, reduce the The effect of footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

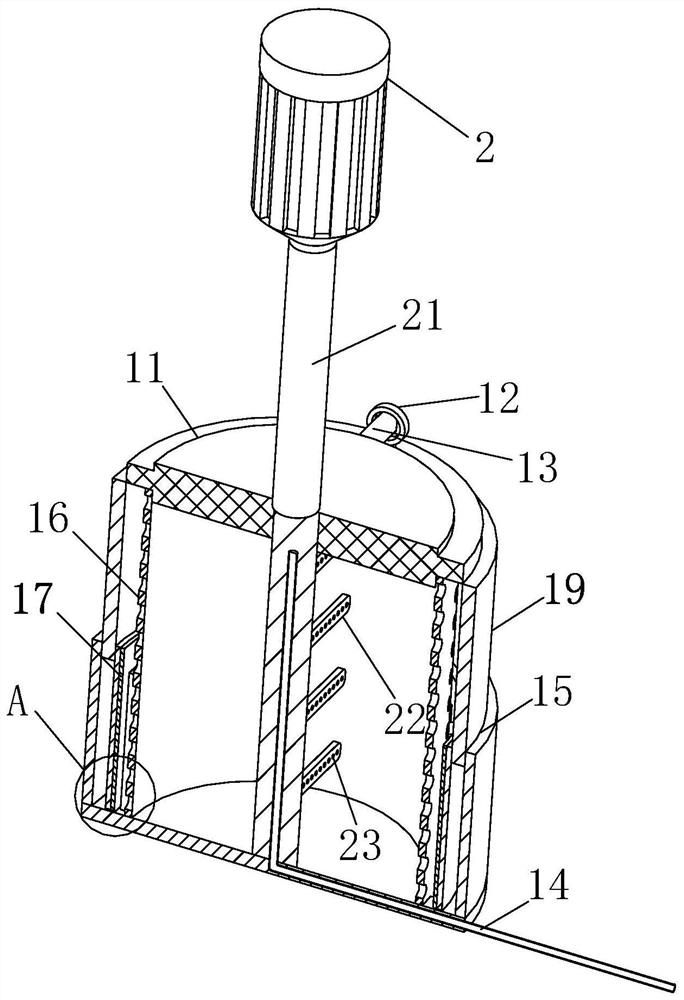

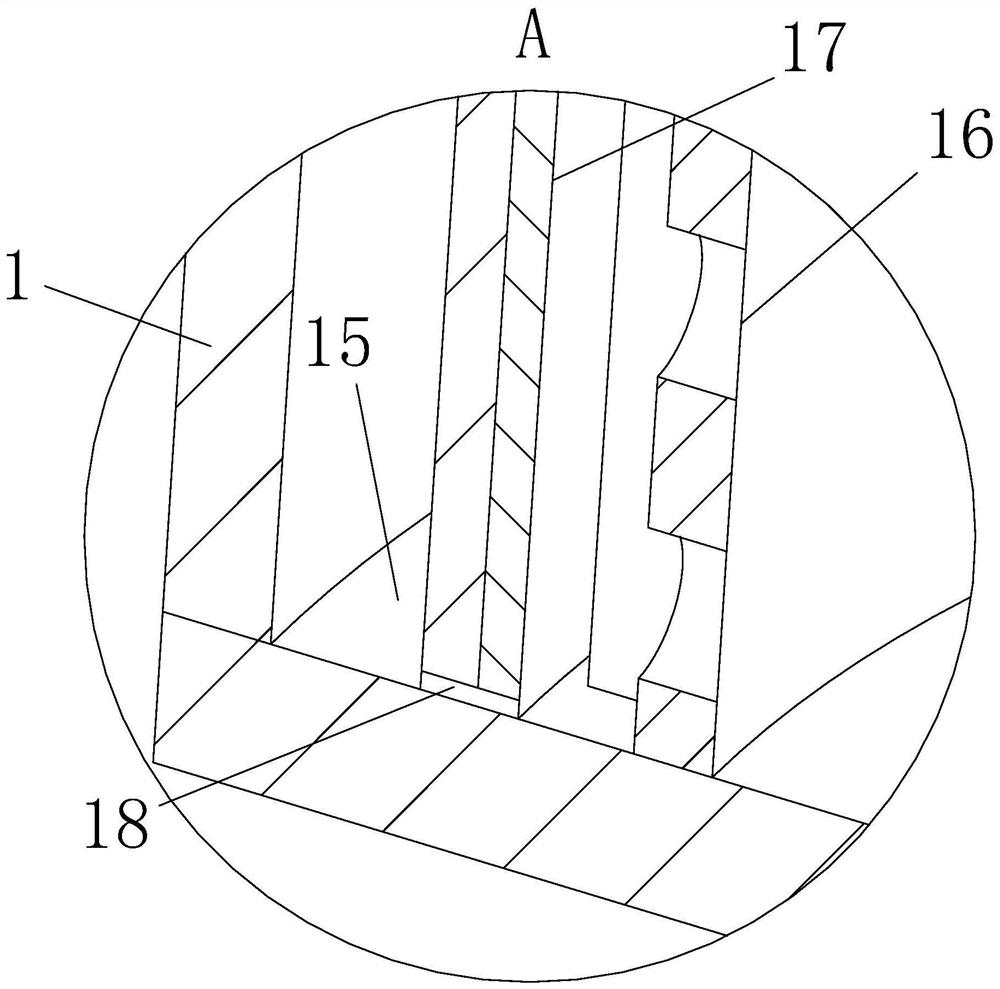

[0035] As an embodiment of the present invention, the conversion unit includes a blocking mechanism 16, which blocks the raw materials in the cooking barrel 1 during the cooling process, and the blocking mechanism 16 is fixedly installed on the On the bottom surface of the cooking barrel 1, the blocking mechanism 16 does not contact the inner wall of the cooking barrel 1, and the upper end of the blocking mechanism 16 is in close contact with the lower surface of the sealing cover 11;

[0036] Sliding mechanism, the sliding mechanism includes a chute 15 and a slide plate 19, the chute 15 is located in the side wall of the cooking barrel 1, the slide plate 19 is sealed and slidably installed in the chute 15, the upper end of the slide plate 19 is in contact with the The lower surface of the sealing cover 11 is in close contact;

[0037] When working, because after cooking the rice, there will be a large amount of hot steam in the cooking barrel 1, and the hot steam will remain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com