Metal composite plate rolling device capable of applying horizontal vibration

A metal composite plate, horizontal technology, applied in the direction of metal rolling, metal rolling, metal rolling frame, etc., can solve the problem of low bonding strength of composite plate, low displacement rate of two metal surfaces and oxide layers, and performance fluctuation range major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be described in further detail below in conjunction with accompanying drawing:

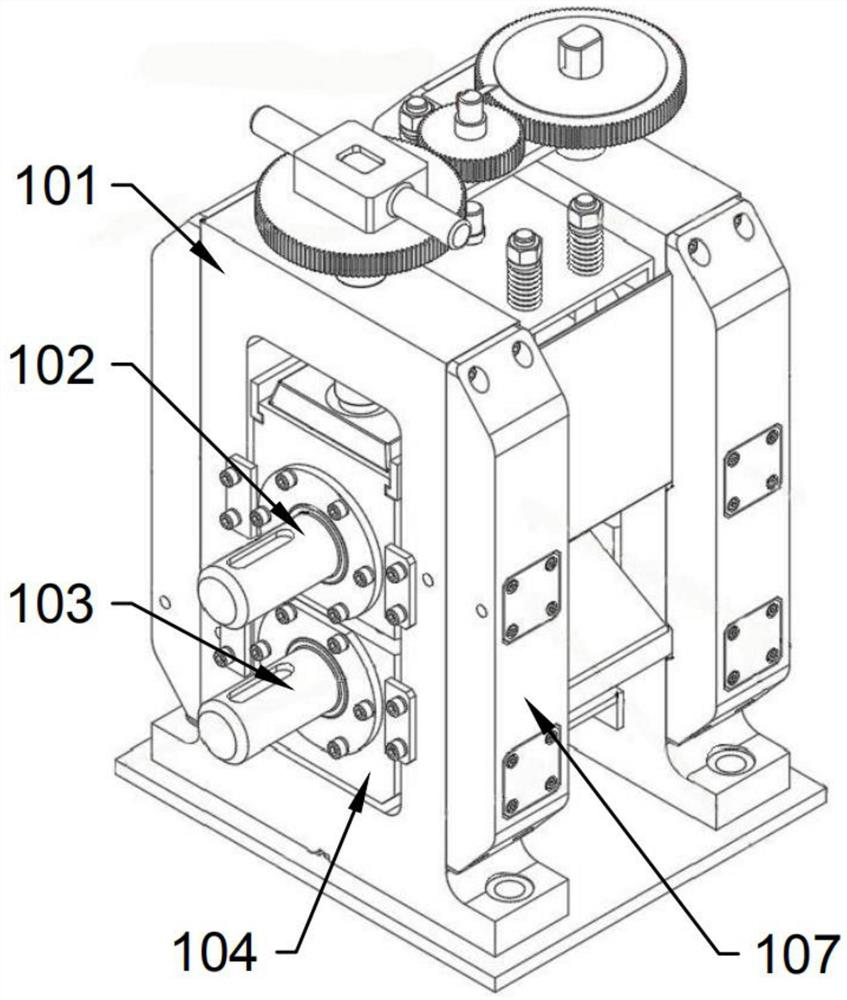

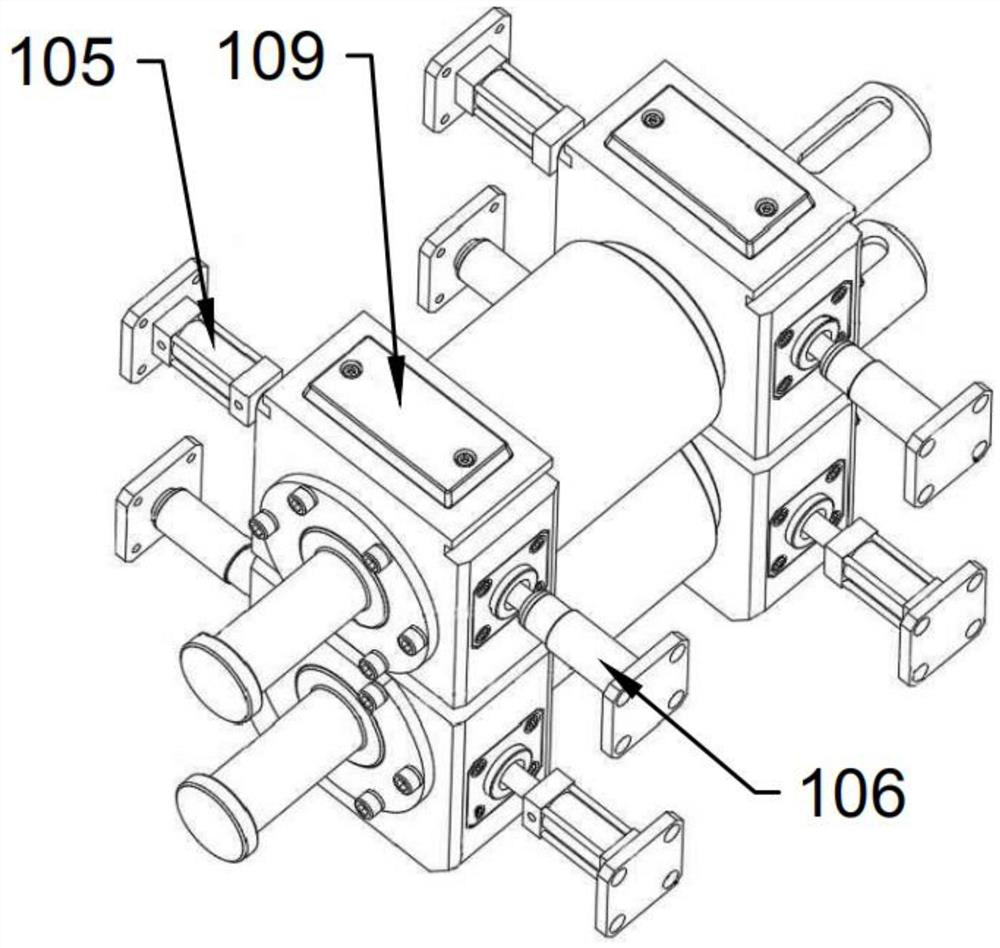

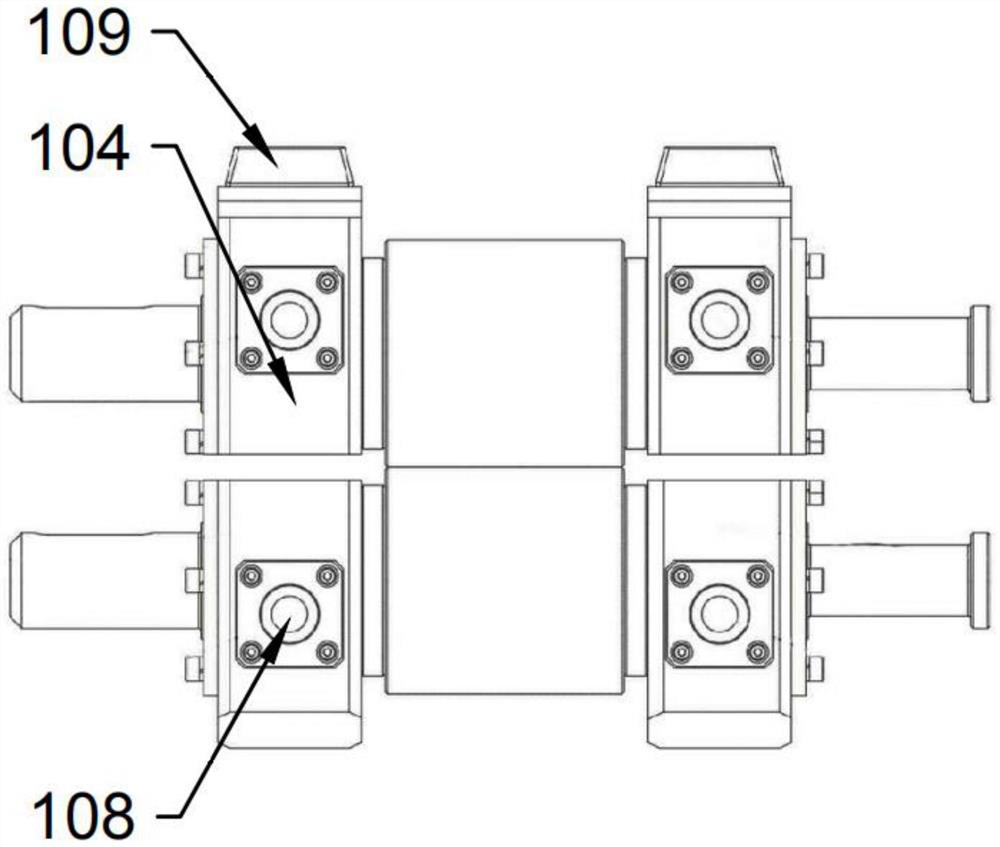

[0027] like Figure 1-Figure 9 As shown, a metal clad plate rolling device capable of applying horizontal vibrations includes symmetrically arranged frames 101, and an upper roll system 102 and a lower roll system 103 are installed between the symmetrically arranged frames 101. Both ends of the upper roller system 102 and the lower roller system 103 are fixed with bearing housings 104, and the outer sides of the bearing housings 104 are provided with horizontal vibration mechanisms to drive the upper roller systems 102 and lower roller systems 103 on the bearing housings 104 to form horizontal vibration;

[0028] Wherein: the horizontal vibration mechanism includes an exciting hydraulic cylinder 105 and a damper 106, and the exciting hydraulic cylinder 105 and the damper 106 are fixedly connected with the front and rear sides of the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com