Clamping and cutting integrated pineapple picker, picking method and picking robot

A picker and pineapple technology, applied in the field of pineapple picking robots, can solve the problems of high labor intensity, labor shortage, labor shortage, etc., and achieve the effects of high clamping accuracy, simple motor structure, and guaranteed success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

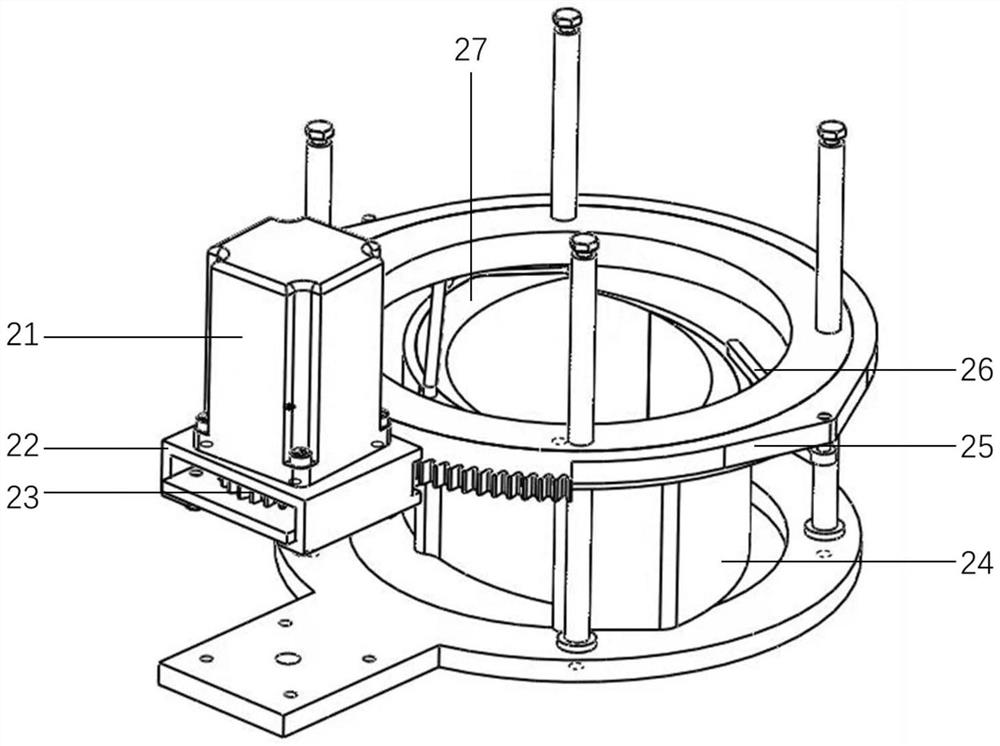

[0035] This embodiment relates to a clip-cut integrated pineapple picker, which specifically includes a three-dimensional frame, a clamping device for fixing pineapples, a cutting device for cutting fruit stems, and a control system.

[0036] The three-dimensional frame comprises an upper annular support plate, a middle annular support plate, a lower annular support plate, and four support plate connecting rods. The upper annular support plate includes a horizontally arranged annular plate, the circular through hole of the upper annular support plate is formed inside the annular plate, and a vertical connecting bracket is fixedly arranged above the upper annular support plate, connecting Four connection holes for fixed connection with an external mobile mechanical arm or movable equipment are uniformly arranged on the bracket. The middle annular support plate includes a horizontally arranged annular plate, a clamping drive connection plate for installing the clamping drive mec...

Embodiment 2

[0047] This embodiment relates to a pineapple picking vehicle-mounted robot. The end effector of the pineapple picking robot is an integrated pineapple picker in the first embodiment. The connecting bracket is fixedly connected with its mechanical driving arm, and at the same time, the controller of the pineapple picking robot is electrically connected with the control circuit of the clipping and cutting integrated pineapple picker, and the software program performs the software fusion connection. The usage method of this embodiment is: the pineapple picking robot drives the mechanical arm to adjust the position of the picker through the pineapple visual recognition and positioning system, and moves the picker to reach the top of the crown leaf of the pineapple; drives the picker to move downward from the top of the pineapple crown leaf to make it The lower annular support plate reaches the pineapple stalk (the pineapple stalk is determined by the photoelectric sensor), and the...

Embodiment 3

[0050] This embodiment relates to a pineapple picking flying robot, which is to replace the carrier in the second embodiment with a pineapple picking flying robot (i.e. an unmanned aerial vehicle). The pineapple picking flying robot includes an upper flying assembly, a lower landing gear, and an integrated The pineapple picker is arranged at the bottom of the flight assembly, between the left and right landing gears.

[0051] The parts not mentioned in this embodiment are the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com