All-solid-state battery cell, preparation method thereof and solid-state battery

一种全固态、电芯的技术,应用在非水电解质蓄电池、锂蓄电池、二次电池等方向,能够解决难以达成全固态电池跨越、无法实现超薄硫化物电解质膜应用等问题,达到降低电芯成本、减小长度、防止内短路的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

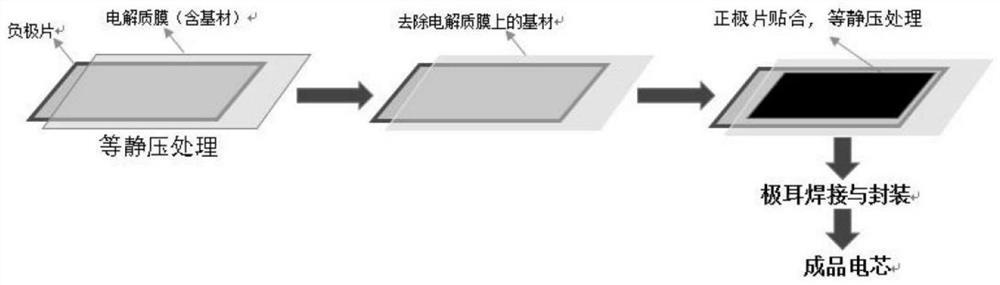

[0083] In this embodiment, an all-solid-state battery cell is prepared according to the following method:

[0084] (1) An electrolyte membrane (Li 10 GeP 2 S 12 (LGPS) electrolyte membrane) is pasted on the negative electrode sheet (single-sided negative electrode sheet, the negative electrode current collector is copper foil, the negative electrode active material layer is composed of negative electrode active material, sulfide electrolyte, conductive agent and binder, and the negative electrode active material is silicon. , the sulfide electrolyte is LGPS, the conductive agent is carbon nanotube CNT, the binder is SBR, and the mass ratio of negative electrode active material, conductive agent and binder is 10:80:5:5), at 100°C Under the pressure of 500MPa, the warm isostatic pressing treatment was carried out, the number of times of pressing was 5 times, and the holding time of each time was 100min, and then the matrix was removed to obtain the first semi-finished battery ...

Embodiment 2

[0091] In this embodiment, an all-solid-state battery cell is prepared according to the following method:

[0092] (1) Lay the electrolyte membrane (thickness and material identical to the electrolyte membrane of Example 1) on the substrate (polytetrafluoroethylene substrate) to the negative electrode sheet (double-sided negative electrode sheet, the negative electrode current collector is copper foil, each The component type and the ratio of the negative electrode active material layer on one side are all the same as the negative electrode active material of embodiment 1) on both sides, carry out isostatic pressing according to the conditions identical with embodiment 1 step (1), remove matrix afterwards, Get the first semi-finished cell.

[0093] (2) On the electrolyte film on both sides of the first semi-finished electric core in step (1), the positive electrode sheet is pasted (the positive electrode collector is aluminum foil, and the component types and ratios of the pos...

Embodiment 3

[0097] In this embodiment, an all-solid-state battery cell is prepared according to the following method:

[0098] (1) An electrolyte membrane (Li 6 P.S. 5 Cl (LPSCl) electrolyte membrane) is pasted on the negative electrode sheet (single-sided negative electrode sheet, the negative electrode current collector is copper foil, the negative electrode active material layer is composed of negative electrode active material, sulfide electrolyte, conductive agent and binder, and the negative electrode active material is Graphite, the sulfide electrolyte is LPSCl, the conductive agent is conductive carbon black SP, the binder is SBR, and the mass ratio of negative electrode active material, conductive agent and binder is 55:40:5:5), on one side at 25 Cold isostatic pressing was performed at a pressure of 500 MPa at a temperature of 5 °C, and the number of times of pressing was 5 times, and the holding time of each time was 300 min. After that, the matrix was removed to obtain the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com