Integrated sample gas suction-assisted dilution module and working method thereof

A working method and sample gas technology, applied in the field of integrated sample gas pumping and dilution modules, can solve problems such as pipeline blockage, achieve the effects of improving reliability, simplifying heat tracing structure, and reducing the probability of problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

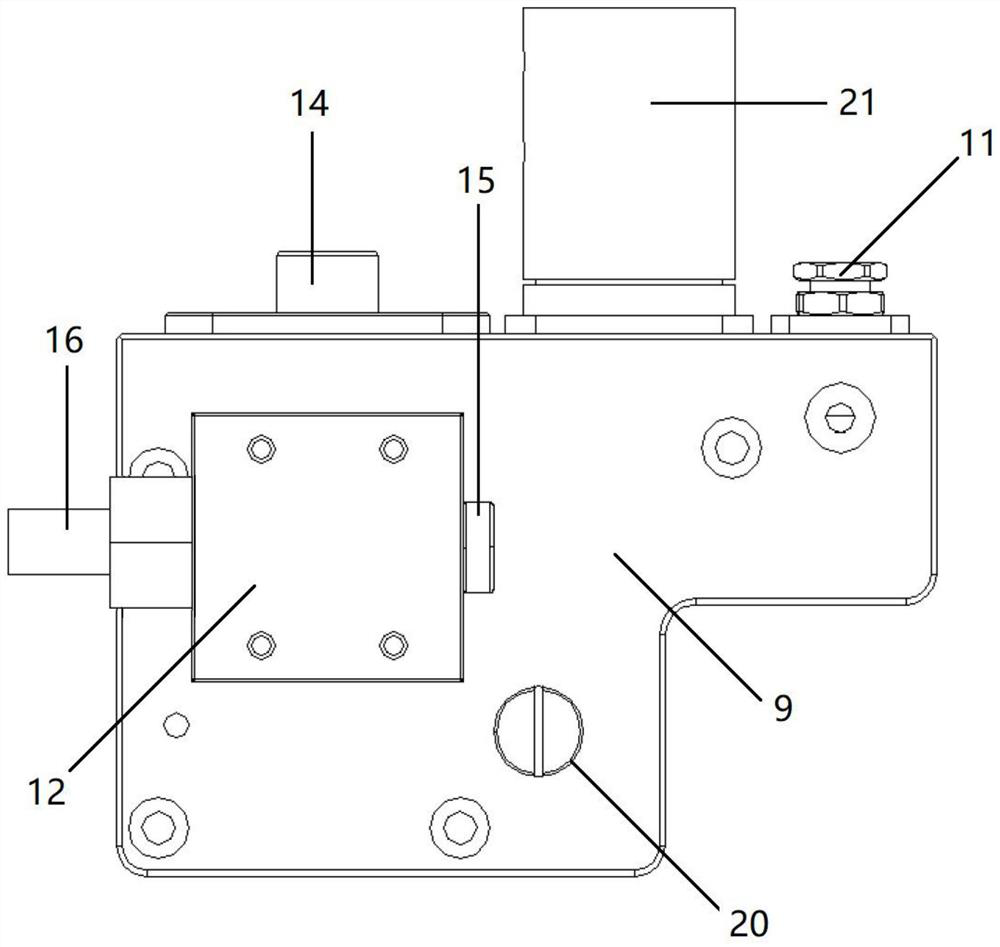

[0034] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings, and the technical solution of the present invention will be explained more clearly and completely.

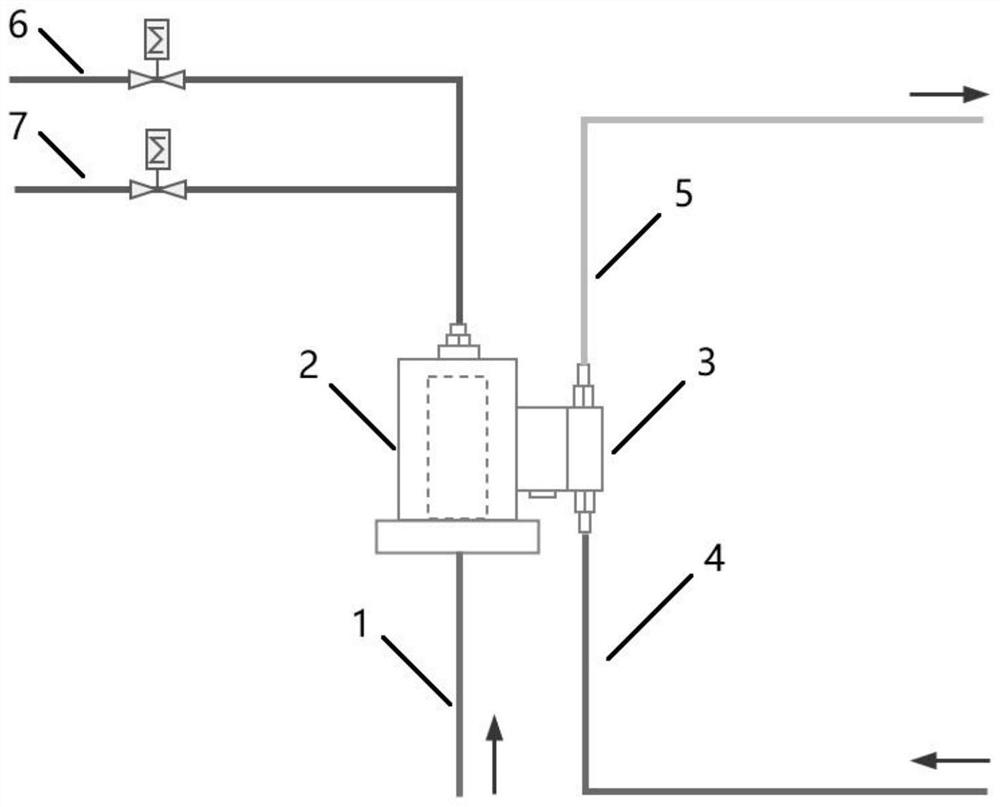

[0035] like figure 1 As shown, the traditional sample gas dilution module includes a sampling tube 1, a filter assembly 2, and a dilution assembly 3 connected in sequence. The filter assembly 2 is connected with a standard gas pipe 6 and a backflushing pipe 7, and the dilution assembly 3 has a zero gas interface 4 oppositely arranged. , Mixed sample gas interface 5. If the sample gas is extracted from the flue only by the traditional dilution module, the replacement of the sample gas in the sampling pipeline is very slow, which will bring a great delay to the measurement results.

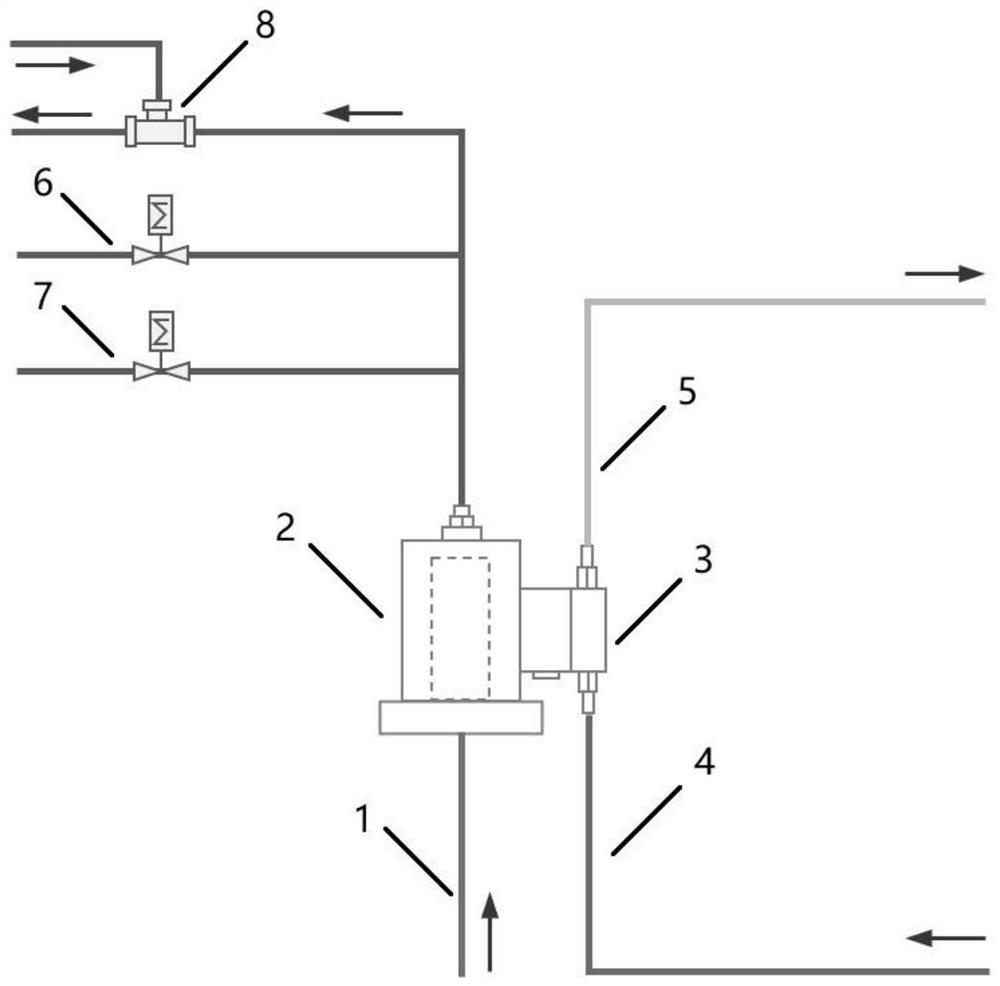

[0036] like figure 2 As shown, in order to accelerate the flow of flue gas to increase the sample gas replacement speed of dilution method sampling, many of them will connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com