Air flame heat energy stove capable of replacing gas for cooking

A flame and air technology, which is applied in the field of air flame heat energy stoves, can solve the problems of scorched bottom rice crust, insufficient crispiness of rice crust, and flame danger, etc., and achieve the effects of improving heating efficiency, avoiding flame loss, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

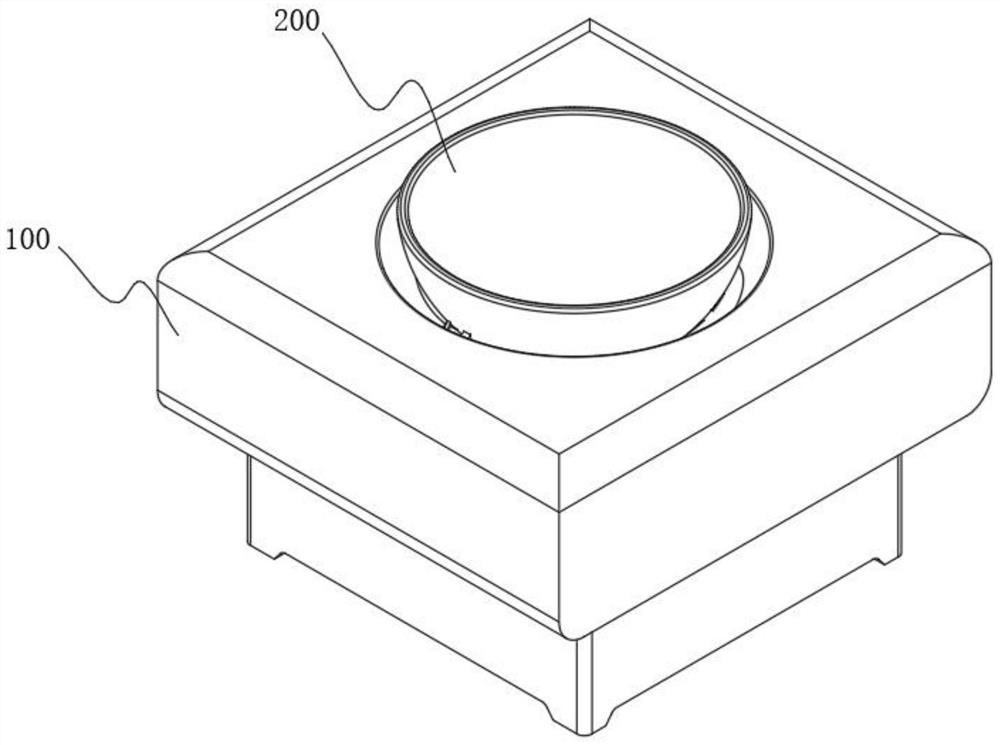

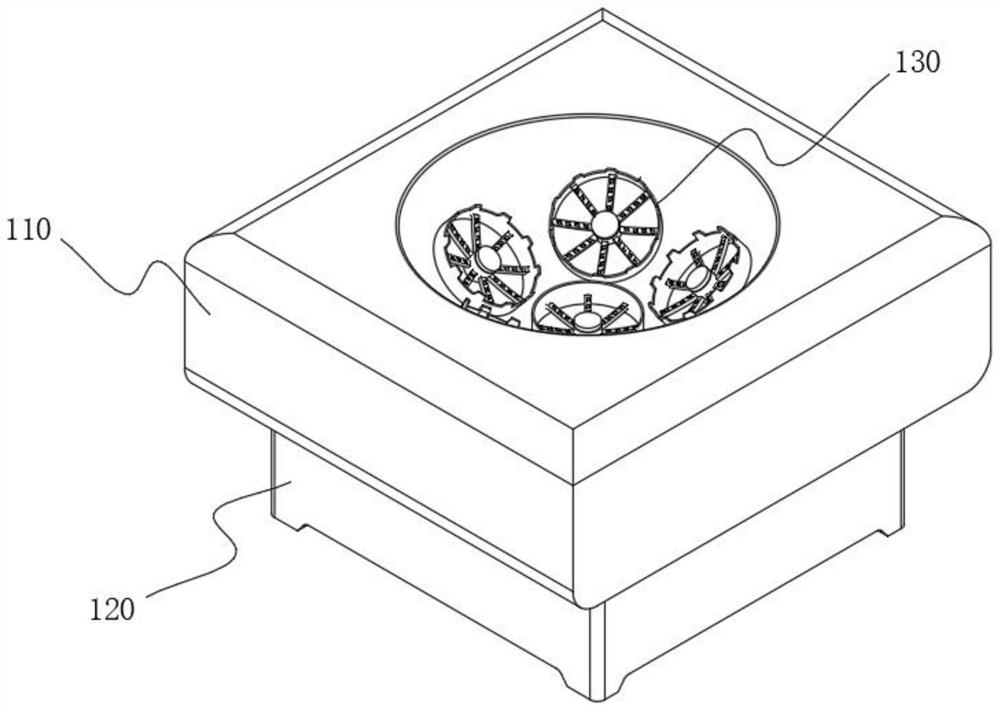

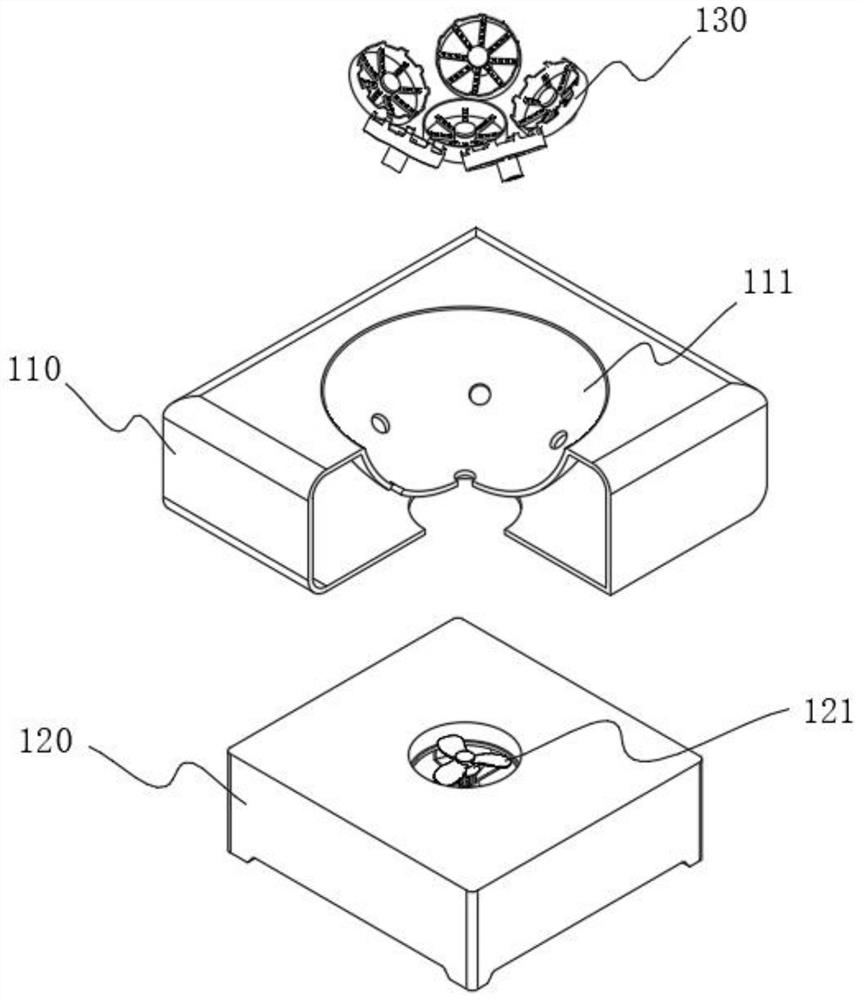

[0045] see figure 1 As shown, the purpose of this embodiment is to provide an air flame thermal energy stove that can replace gas cooking, including a stove body 100 and a pot body 200, please refer to figure 2 and image 3As shown, the cooker body 100 includes a cooker 110 and a cooker frame 120 arranged at the bottom of the cooker 110. The top of the cooker 110 is provided with an accommodating groove 111. The accommodating groove 111 is hemispherical. Put in the groove 111, a plurality of flame generating mechanisms 130 are set in the containing groove 111, please refer to Figure 4 shown, where:

[0046] The flame generating mechanism 130 includes a flame generating tube 131, a plurality of transmission tubes 132 are arranged in a ring around the flame generating tube 131, and the transmission tube 132 communicates with the flame generating tube 131, and a plurality of flame injection ports 1321 are arranged on the top of the transmission tube 132, and the flame generat...

Embodiment 2

[0053] Considering that when cooking, it is necessary to flip the spoon. If there is no flame, the effect of flipping the spoon cannot be achieved. By setting one of the flame generating mechanisms 130 in the center of the accommodating groove 111, the rest The flame generating mechanism 130 is set with the flame generating mechanism 130 at the central position as the center of a circle to form the peripheral flame generating mechanism 130. The working principle is as follows:

[0054] see Figure 7 As shown, the top edge of the isolation ring 133 of the peripheral flame generating mechanism 130 is provided with a plurality of through grooves 1331 in a circular shape, so that the flames generated in this way can emerge from the through grooves 1331 to complete the effect of flipping the spoon;

[0055] Also, see Figure 8 As shown, when used in a restaurant, a flame arresting ring 112 is provided on the top edge of the accommodating tank 111 by means of magnetic attraction. T...

Embodiment 3

[0059] Considering that once the pot body 200 is bonded to the flame arresting ring 112, the gap formed between the pot body 200 and the accommodating groove 111 will be sealed, and the amount of air entering will decrease, thereby affecting the combustion of the air flame. For example open flame trap 1121, see Figure 9 As shown, the flame arresting ring 112 has a flame arresting hole 1121 penetrating from the inside to the outside, and a plurality of flame arresting holes 1121 are formed in a circular shape on the flame arresting ring 112, please refer to Figure 10 As shown, the flame arresting hole 1121 specifically includes a flame inlet portion 1121A, an expansion hole portion 1121B, and a converging hole portion 1121C. The flame inlet portion 1121A is provided on the inner wall of the flame arresting ring 112, and the expansion hole portion 1121B and the converging hole portion 1121C are in sequence. Open at the outer end of the flame inlet portion 1121A, and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com