Method for enhancing electroreduction of carbon dioxide to generate carbon monoxide through external magnetic field

A carbon dioxide and carbon monoxide technology, applied in the field of electrochemistry, can solve the problems of inappropriateness, consumption of flow electrolytic cells, limited current density, etc., to achieve the effect of performance degradation, waste reduction, and permanent stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

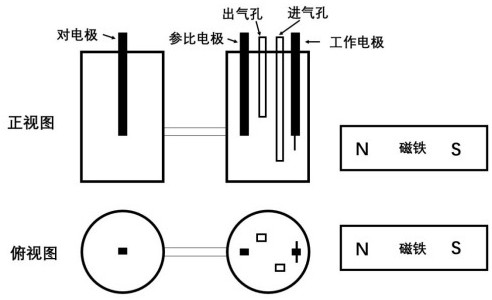

Method used

Image

Examples

Embodiment 1

[0043] First weigh Zn(NO 3 ) 2 ·6H 2 O1.5 mmol, dissolved in 3 ml of deionized water, weighed 2-methylimidazole (5.5 g) and dissolved in 20 ml of deionized water, then mixed the above two solutions, and stirred at room temperature for 6 h. After the stirring was completed, it was centrifuged several times, 3 times, at 5000 rpm, and then dried overnight in an oven at 80 °C for 12 h to obtain a solid sample. Then weigh an equal mass of Ni(NO 3 ) 2 ·6H 2 O, dissolved together with the solid sample in 10 ml of alcohol-water mixture (volume ratio of ethanol: water: 1:1), stirred at room temperature for 4 h, and dried overnight at 80 °C for 12 h. Finally put it at 900 °C, N 2 Under atmosphere protection, the heating rate was 2°C / min, fired for 3.5 h, cooled to room temperature, pickled with 1 M hydrochloric acid for 2 h, finally washed with water, filtered and dried. Obtain MOF-Zn / Ni.

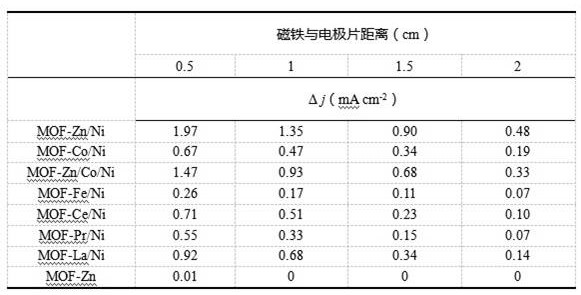

[0044] Current density increase (Δ j ) reaches a maximum value of 1.97 mA cm -2 . This...

Embodiment 2

[0046] Another scheme for preparing the catalyst, first weigh the Co(NO 3 ) 2 ·6H 2 O 1.5 mmol was dissolved in 3 ml of deionized water, 5.5 g of 2-methylimidazole was dissolved in 20 ml of deionized water, and then the above two solutions were mixed and stirred at room temperature for 6 h. After the stirring was completed, it was centrifuged several times, 3 times, at 5000 rpm, and then dried overnight in an oven at 80 °C for 12 h to obtain a solid sample. Then weigh an equal mass of Ni(NO 3 ) 2 ·6H 2 O, dissolved together with the solid sample in 10 ml of alcohol-water mixture, the volume ratio of ethanol: water was 1:1, stirred at room temperature for 4 h, and dried overnight at 80 °C for 12 h. Finally put it at 900 °C, N 2 Under atmosphere protection, the heating rate was 2 ℃ / min, fired for 3.5 h, cooled to room temperature, pickled with 1 M hydrochloric acid for 2 h, finally washed with water, filtered and dried. Obtain MOF-Co / Ni.

Embodiment 3

[0048] First weigh Zn(NO 3 ) 2 ·6H 2 O0.5 mmol, and Co(NO 3 ) 2 ·6H 2 O1.0 mmol, dissolved in 3 ml of deionized water, 5.5 g of 2-methylimidazole, dissolved in 20 ml of deionized water, then mixed the above two solutions, stirred at room temperature for 6 h. After the stirring was completed, it was centrifuged several times, 3 times, at 5000 rpm, and then dried overnight in an oven at 80 °C for 12 h to obtain a solid sample. Then weigh an equal mass of Ni(NO 3 ) 2 ·6H 2 O, dissolved together with the solid sample in 10 ml of alcohol-water mixture with a volume ratio of ethanol:water of 1:1, stirred at room temperature for 4 h, and then dried overnight at 80 °C for 12 h. Finally put it at 900 °C, N 2 Under atmosphere protection, the heating rate was 2 ℃ / min, fired for 3.5 h, cooled to room temperature, pickled with 1 M hydrochloric acid for 2 h, finally washed with water, filtered and dried. Obtain MOF-Zn / Co / Ni.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com