An environmental protection sludge separation device

A separation device and environmental protection technology, applied in the direction of sludge treatment, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problem that sludge is prone to bacteria, equipment dry block sludge affects equipment separation Efficiency, the scope of equipment work and other issues, to achieve the effect of increasing stability, enhancing disinfection effect, and speeding up the filtration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

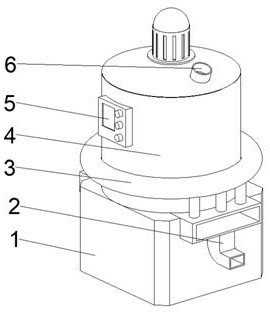

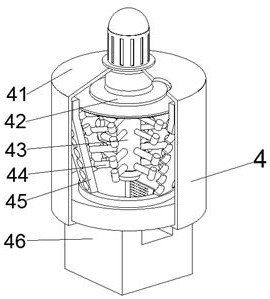

[0042] see Figure 1-6 , the present invention provides a technical solution: an environmental protection sludge separation device, including a static main body 1, through which the water contained in the sludge can be stored, and the static main body 1 performs storage during storage. The static sedimentation of the sewage reduces the situation that the discharged sewage still has a large amount of impurities. The middle position of the top of the outer wall on both sides of the static main body 1 is connected with a multi-layer discharge box 2, which is separated by the multi-layer discharge box 2. The sewage and sludge are discharged at different positions, thereby avoiding the re-mixing of sludge and sewage during discharge, and the multi-layer discharge box 2 is not easy to be blocked when discharging, effectively speeding up the discharge of sewage The top of the static main body 1 is fixedly connected with the processing device 4, the bottom of the processing device 4 r...

Embodiment 2

[0049] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for using an environmental protection sludge separation device, which is characterized in that: Step 1: The equipment is installed, and the static main body 1 and the multi-layer outlet The material box 2 is communicated, the processing device 4 is connected with the energy source, the processing device 4 is communicated with the feed pipe 6, and the static main body 1 is communicated with the processing device 4;

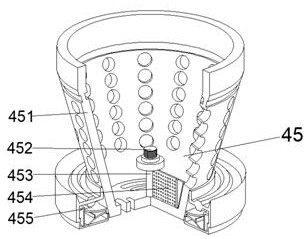

[0050] Step 2: When the sludge enters the separation tank 41 through the elastic barrier plate 42, it is tilted by the pressure of the sludge, so that the sludge falls into the filter device 45, and the rotating shaft 43 is driven by the motor to rotate, and Utilize the separating rod 44 that is connected on the rotating shaft 43 to pulverize the massive sludge that it contacts, and the separating tank 41 is fixedly connected with the filtering devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com