Noodles containing bacillus coagulans BC99 and making method of noodles

A technology of Bacillus coagulans and a production method, which are applied in the field of food processing to achieve the effects of increasing nutrition and health care functions, inhibiting pathogenic bacteria, and maintaining balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

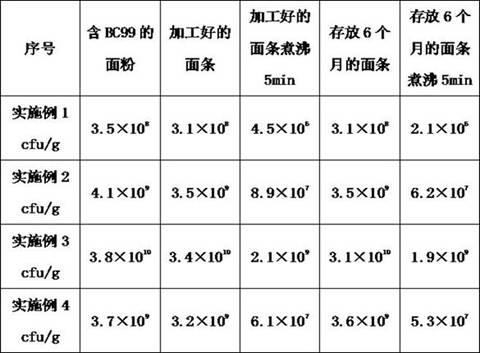

Examples

Embodiment 1

[0019] A kind of noodle of bacillus coagulans BC99, the manufacturing process comprises the following steps:

[0020] (1) Add 3g of edible salt to 1000g of special first-class flour and mix well.

[0021] (2) Select the number of spores of Bacillus coagulans BC99 at 10 11 Mix the CFU / g bacteria powder and the flour in (1) at a ratio of 1:1000, so that the final number of spores of BC99 is 10 8 CFU / g, mix well by flour mixer.

[0022] (3) Add the well-stirred BC99 flour into the dough mixer, slowly add 0.3L of pure water into the dough mixer, and knead the dough for 15 minutes.

[0023] (4) The prepared initial dough is rested for 10 minutes, and the rested dough is put into a noodle press to make wet noodles.

[0024] (5) Dry the noodles containing BC99, and the wet noodles made are preferably medium-temperature and medium-speed drying method: pre-drying at 35°C, the drying time is about 1h; main drying is at 45°C, the drying time is about 2.5h, and the drying is completed ...

Embodiment 2

[0027] A kind of noodle of bacillus coagulans BC99, the manufacturing process comprises the following steps:

[0028] (1) Add 1g of edible salt to 1000g of special first-class flour and mix well.

[0029] (2) Select the number of spores of Bacillus coagulans BC99 at 10 11 Mix the CFU / g bacteria powder and the flour in (1) at a ratio of 10:1000, so that the final number of spores of BC99 is 10 9 CFU / g, mix well by flour mixer.

[0030] (3) Add the well-stirred BC99 flour into the dough mixer, slowly add 0.3L of pure water into the dough mixer, and knead the dough for 15 minutes.

[0031] (4) The prepared initial dough is rested for 10 minutes, and the rested dough is put into a noodle press to make wet noodles.

[0032] (5) Dry the noodles containing BC99, and the wet noodles made are preferably medium-temperature and medium-speed drying method: pre-drying at 35°C, drying time is about 1h; main drying is at 45°C, drying time is about 2.5h, and drying is completed at 20-25°C ...

Embodiment 3

[0035] (1) Add 30g of edible salt to 1000g of special first-class flour and mix well.

[0036] (2) Select the number of spores of Bacillus coagulans BC99 at 10 11 Mix the CFU / g bacteria powder and the flour in (1) at a ratio of 100:1000, so that the final BC99 spore count is 10 10 CFU / g, mix well by flour mixer.

[0037] (3) Add the well-stirred BC99 flour into the dough mixer, slowly add 0.35L of pure water into the dough mixer, and knead the dough for 20 minutes.

[0038] (4) The prepared initial dough is rested for 15 minutes, and the rested dough is put into a noodle press to make wet noodles.

[0039] (5) Dry the noodles containing BC99, and the wet noodles made are preferably medium-temperature and medium-speed drying method: pre-drying at 35°C, drying time is about 1h; main drying is at 45°C, drying time is about 2.5h, and complete drying is at 25°C. About 1h.

[0040] (6) The dried noodles are cut, measured and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com