Safety valve for low-temperature and low-pressure working conditions

A low-temperature, low-pressure, safety valve technology, used in safety valves, lift valves, balance valves, etc., can solve problems such as inappropriateness, low spring preload, and unfavorable surface deformation of sealing blocks, and achieve the effect of solving limited use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

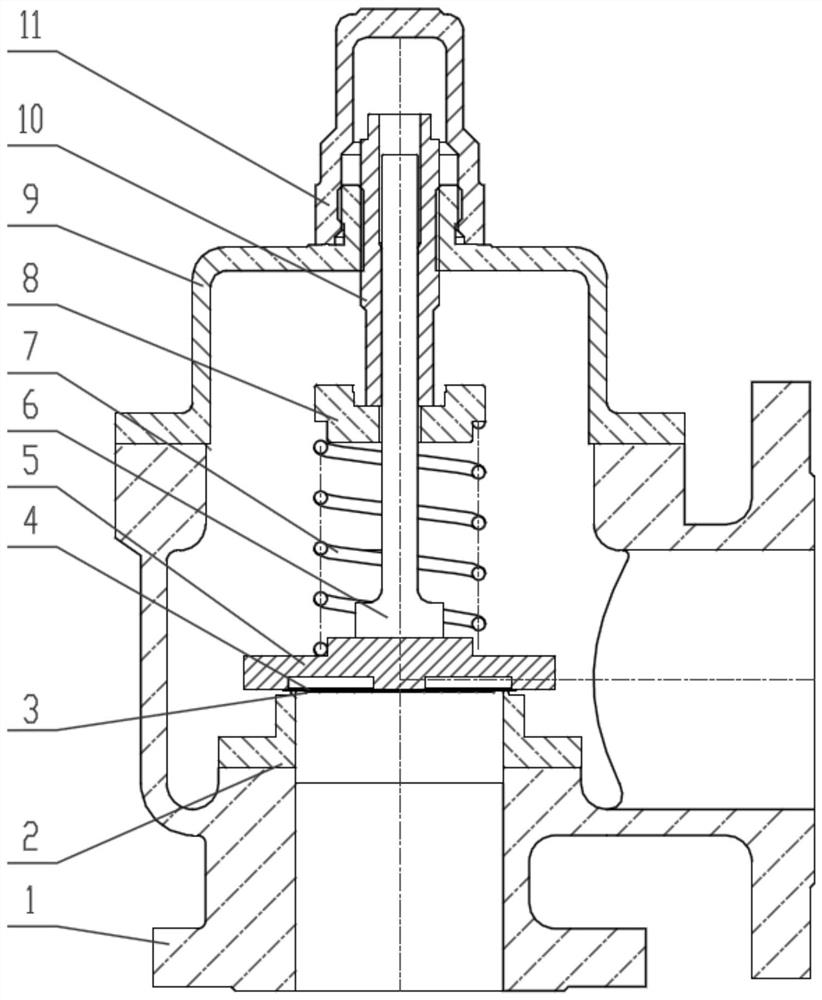

[0023] In order to solve the problem of low temperature and low pressure working conditions such as liquid nitrogen storage tanks, it is not suitable to use commonly used metal seals, seal block seals and O-ring seals. The safety valve provided by the embodiment of the present invention has the following characteristics:

[0024] Brand-new sealing structure: the seal between the valve seat and disc adopts FEP diaphragm soft sealing structure, FEP material can withstand low temperature conditions, and the FEP diaphragm structure still has good ductility guarantee under low pressure, ensuring low temperature and low pressure The sealing performance of the safety valve under working conditions.

[0025] Lightweight internal structure: the lower spring seat is integrated with the valve disc, and the valve stem and adjusting screw are used for guiding structure, which cancels the traditional guiding parts, makes the structure of the whole valve more compact, realizes the light weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com