Hydrogen-aluminum metal compound and preparation method thereof

A technology of metal composites and aluminum hydrogen, applied in the production of hydrogen, etc., can solve the problems of complex design of hydrogen preparation methods, and achieve the effect of efficient and safe preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

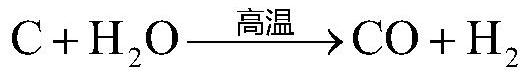

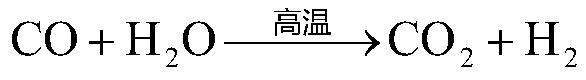

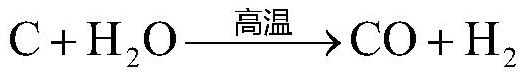

Method used

Image

Examples

Embodiment 1

[0032] The invention provides a hydrogen-aluminum metal composite, select two groups of 20 parts by weight of aluminum powder, two groups of 2 parts of hydrochloric acid as a trigger, 5 parts by weight of pure water, and the composite also includes 10 parts by weight of carbon powder, 12 parts of organic solvent, 4 parts of solid sodium hydroxide, the concentration of the hydrochloric acid is set to 12mol / L-20mol / L, and the organic solvent can be ethanol.

[0033] Further, in the above technical solution, in the preparation method of the hydrogen-aluminum metal complex, the reactor is first divided into a first reaction zone and a second reaction zone;

[0034] Further, in the above technical scheme, 20 parts by weight of aluminum powder, 10 parts by weight of carbon powder, 12 parts of ethanol and 2 parts of hydrochloric acid with a concentration of 15mol / L are put into the first reaction zone; 20 parts by weight of aluminum Powder, 5 parts by weight of pure water, 4 parts of...

Embodiment 2

[0049] The invention provides a hydrogen-aluminum metal composite. Two groups of 20 parts by weight of aluminum powder, two groups of 1 part of hydrochloric acid are used as a trigger, 3 parts by weight of pure water, and the composite also includes 6 parts by weight of carbon powder. 10 parts of organic solvent, 3 parts of solid sodium hydroxide, the concentration of the hydrochloric acid is set to 12mol / L-20mol / L, and the organic solvent is ethanol.

[0050] Further, in the above technical solution, in the preparation method of the hydrogen-aluminum metal complex, the reactor is first divided into a first reaction zone and a second reaction zone;

[0051] Further, in the above technical scheme, 20 parts by weight of aluminum powder, 6 parts by weight of carbon powder, 10 parts of ethanol and 1 part of hydrochloric acid with a concentration of 12mol / L are put into the first reaction zone; 20 parts by weight of aluminum Powder, 3 parts by weight of pure water, 3 parts of solid...

Embodiment 3

[0066] The invention provides a hydrogen-aluminum metal composite. Two groups of 20 parts by weight of aluminum powder, two groups of 3 parts of hydrochloric acid are used as triggers, 6 parts of pure water by weight, and the composite also includes 12 parts by weight of carbon powder. 15 parts of organic solvent, 5 parts of solid sodium hydroxide, the concentration of the hydrochloric acid is set to 12mol / L-20mol / L, and the organic solvent is ethanol.

[0067] Further, in the above technical solution, in the preparation method of the hydrogen-aluminum metal complex, the reactor is first divided into a first reaction zone and a second reaction zone;

[0068] Further, in the above technical scheme, 20 parts by weight of aluminum powder, 12 parts by weight of carbon powder, 15 parts of ethanol and 1 part of hydrochloric acid with a concentration of 20mol / L are put into the first reaction zone; 20 parts by weight of aluminum powder, 6 parts by weight of pure water, 5 parts of sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com