Tool locking ram structure of turning and milling composite equipment

A technology of compound equipment and ram, which is applied in the field of tool locking ram structure of turning and milling compound equipment, can solve the problems of time-consuming, troublesome process, and inability to guarantee the quality and precision of parts processing, so as to reduce the number of clamping and improve the Production efficiency, the effect of reducing production assistance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

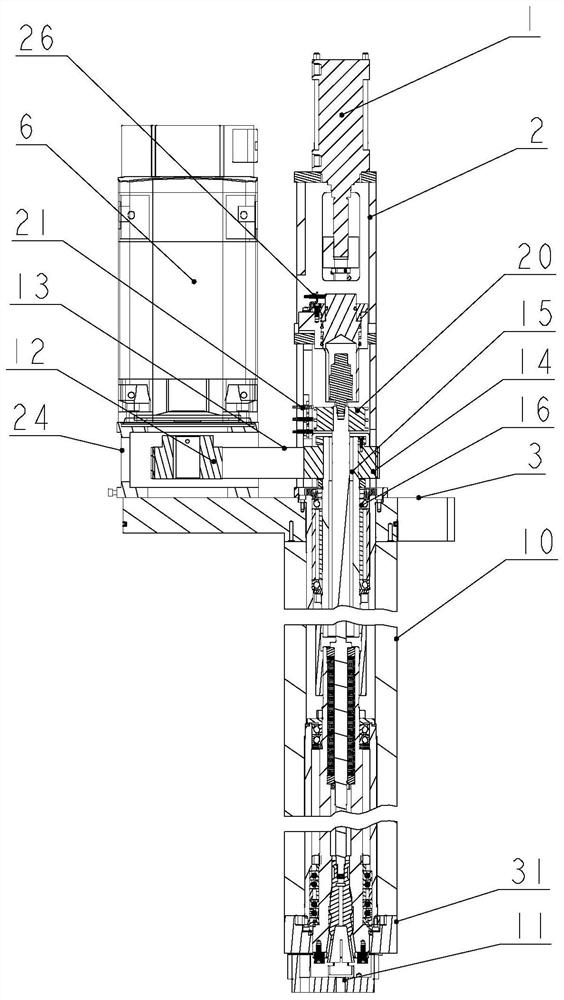

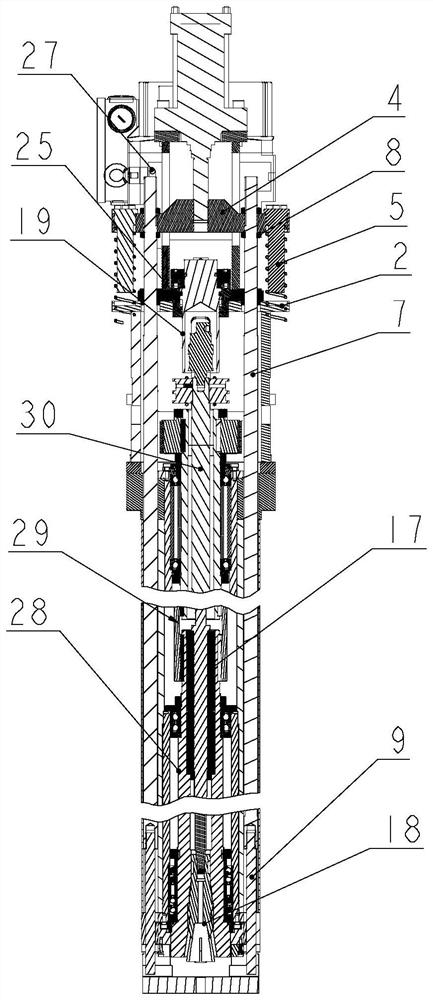

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] Such as Figure 1-Figure 2 As shown, the turning tool oil cylinder 1 is installed on the fixed seat 2, the fixed seat 2 is installed on the fixed plate 3, and the fixed plate 3 is fixed on the upper end of the ram 10; the turning tool oil cylinder 1 piston is connected with the support 4, and the two sides of the support 4 The pull rod 7 is fixed by the lock nut 8, the limit rod 5 is fixed on the outside of the support 4; one end of the T-shaped clamp rod 9 is fixed with the pull rod 7; the T-shaped clamp rod 9 is connected with the T-shaped groove of the turning tool holder 11; the induction switch 27 Installed on the bracket 2, it is used to monitor the position of the pull rod 7.

[0018] The motor 6 is installed on the motor base 24, and the motor base 24 is installed on the fixed plate 3; the first pulley 12 is installed on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com