High-precision internal-cooling ball screw internal-cooling deep hole machining numerical control special machine tool

A special machine tool and cooling roller technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problem of particularly high coaxiality requirements between the tool and the shaft to be processed, large runout of shaft workpieces, and inability to achieve deep depth. Hole processing and other problems, to achieve the effect of ingenious design, high-precision coaxiality requirements, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

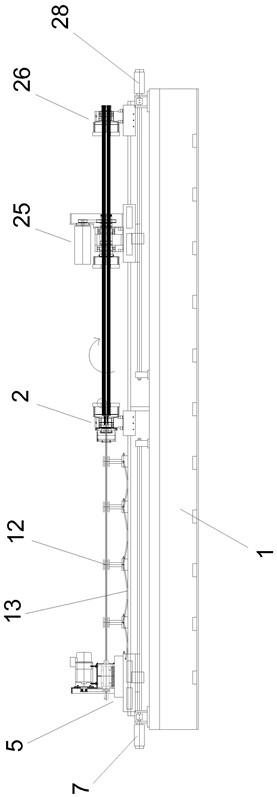

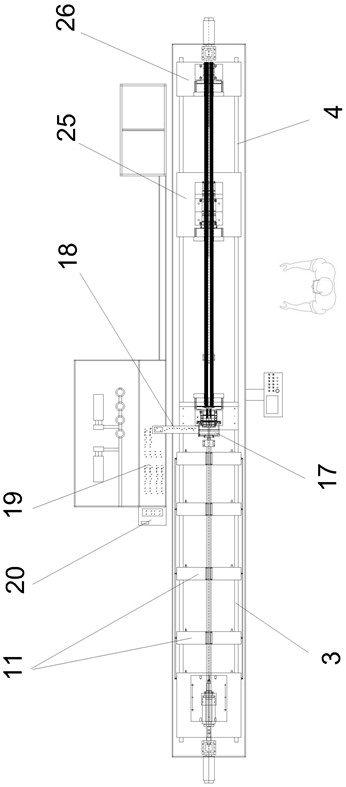

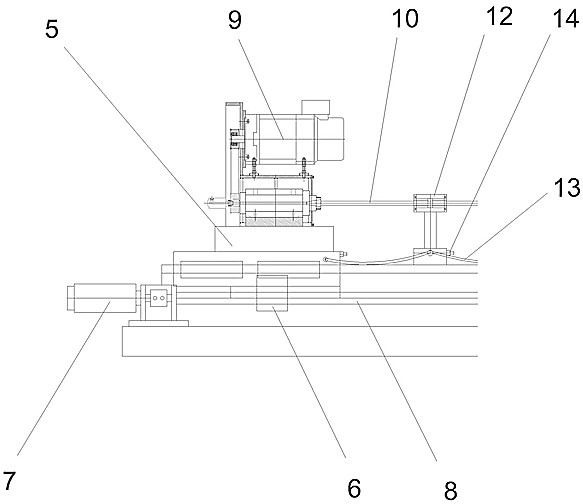

[0026] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figure 1 to Figure 7 Shown: a high-precision internal cooling ball screw internal cooling deep hole processing CNC special machine tool, which includes a bed body 1 as a base, a fixed seat 2 is arranged in the middle of the bed body 1, and the two sides of the fixed seat 2 A pair of first linear slide rails 3 and a pair of second linear slide rails 4 are respectively arranged on the bed body 1, and the first linear slide rails 3 and the second linear slide rails 4 are all along the length direction of the bed body 1 distributed,

[0027]A tool slide 5 is slidably connected to the first linear slide rail 3, the bottom of the tool slide 5 is provided with a first screw block 6, and a tool feed motor 7 is also provided on the bed body 1, and the tool The working end of the feed motor 7 is connected to the first lead screw 8 which is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com