Catalyst for preparing methyl acetate through carbonylation of dimethyl ether as well as preparation method and application of catalyst

A technology of methyl acetate and solid acid catalyst, applied in the field of catalytic chemistry, can solve the problems of equipment maintenance cost, environmental pollution, high cost and the like, and achieve the effects of good industrial application prospect, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

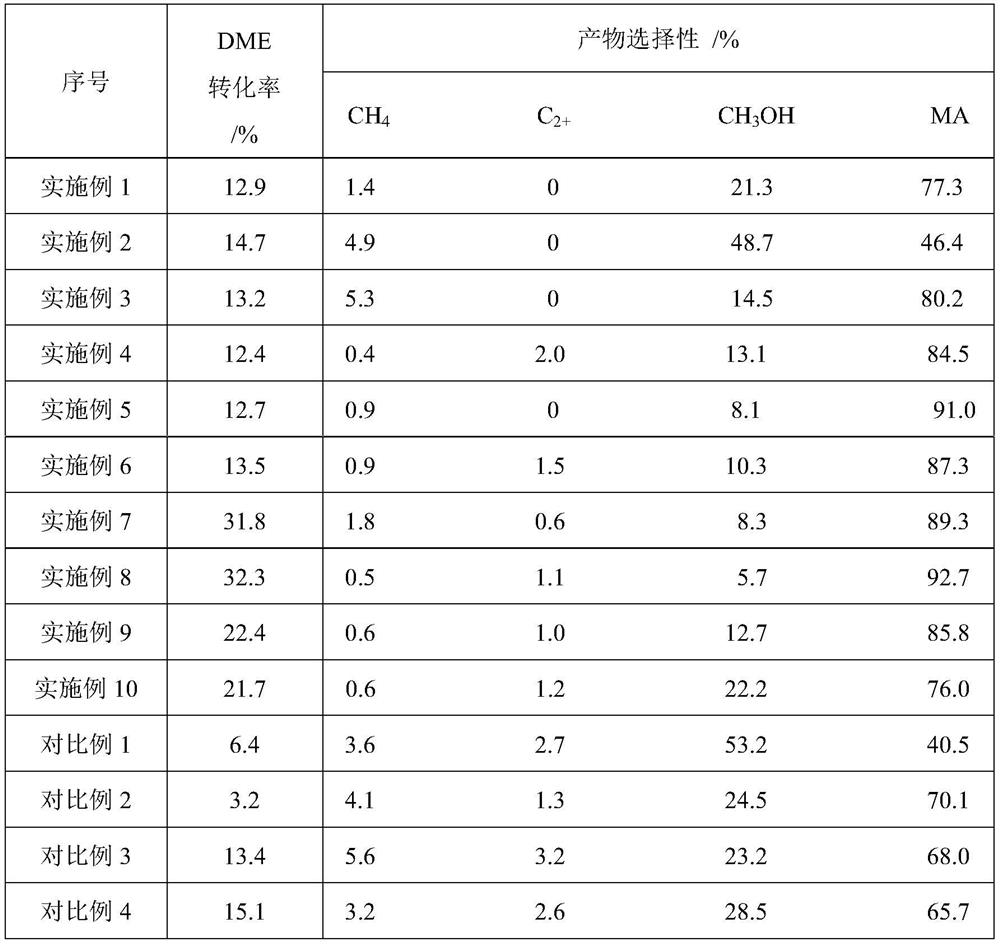

Examples

Embodiment 1

[0026] Weigh 1.0g solid acid Nb 2 o 5 ·nH 2 O powder was added to 100 mL of deionized water and stirred vigorously. Then accurately weigh 1.0mL to a concentration of 0.02mol L -1 RuCl 3 The solution was dissolved in deionized water to prepare 10 mL of noble metal solution, and slowly injected into the vigorously stirred solid acid suspension through a syringe pump at an injection speed of 5.0 mL / h. After the injection was completed, the resulting mixed solution was stirred at room temperature for 24 h. Transfer the fully mixed mixed solution to a rotary evaporator, and realize solid-liquid separation at a water bath temperature of 80°C to obtain Nb loaded with Ru metal elements. 2 o 5 ·nH 2 O solid. Then after the obtained solid is ground evenly, pass into H 2 Concentration of 5% H 2 -Ar mixed gas for reduction, temperature 320°C, time 4h. The reduced solid is compressed into tablets to obtain the catalyst.

[0027] The reaction conditions for the catalyst to be us...

Embodiment 2

[0029] Weigh 1.0g solid acid Nb 2 o 5 ·nH 2 O powder was added to 100 mL of deionized water and stirred vigorously. Then accurately weigh 1.0mL to a concentration of 0.02mol L -1 RhCl 3 The solution was dissolved in deionized water to prepare 10 mL of noble metal solution, and slowly injected into the vigorously stirred solid acid suspension through a syringe pump at an injection speed of 5.0 mL / h. After the injection was completed, the resulting mixed solution was stirred at room temperature for 24 h. Transfer the fully mixed mixed solution to a rotary evaporator, and realize solid-liquid separation at a water bath temperature of 80°C to obtain Nb loaded with Rh metal elements. 2 o 5 ·nH 2 O solid. Then after the obtained solid is ground evenly, pass into H 2 Concentration of 5% H 2 -Ar mixed gas for reduction, temperature 320°C, time 4h. The reduced solid is compressed into tablets to obtain the catalyst.

[0030] The reaction conditions for the catalyst to be us...

Embodiment 3

[0032] Weigh 1.0g solid acid WO 3 / ZrO 2 powder, added to 100 mL of deionized water and stirred vigorously. Then accurately weigh 1.0mL to a concentration of 0.02mol L -1 RhCl 3 The solution was dissolved in deionized water to prepare 10 mL of noble metal solution, and slowly injected into the vigorously stirred solid acid suspension through a syringe pump at an injection speed of 5.0 mL / h. After the injection was completed, the resulting mixed solution was stirred at room temperature for 24 h. The fully mixed mixed solution was transferred to a rotary evaporator, and the solid-liquid separation was realized at a water bath temperature of 80°C to obtain WO loaded with Rh metal elements. 3 / ZrO 2 solid. Then after the obtained solid is ground evenly, pass into H 2 Concentration of 5% H 2 -Ar mixed gas for reduction, temperature 320°C, time 4h. The reduced solid is compressed into tablets to obtain the catalyst.

[0033] The reaction conditions for the catalyst to be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com