Preparation method of combined gas guide graphite electrode and quartz crucible without inner surface bubble group

A graphite electrode and quartz crucible technology, which is applied in glass manufacturing equipment, electrical components, electric heating devices, etc., can solve problems such as crucible foreign matter falling into the quartz crucible, melting of the lower end of the quartz tube sheath, and defects in condensate bubble groups. , to avoid silica condensation, reduce oxidation consumption, and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

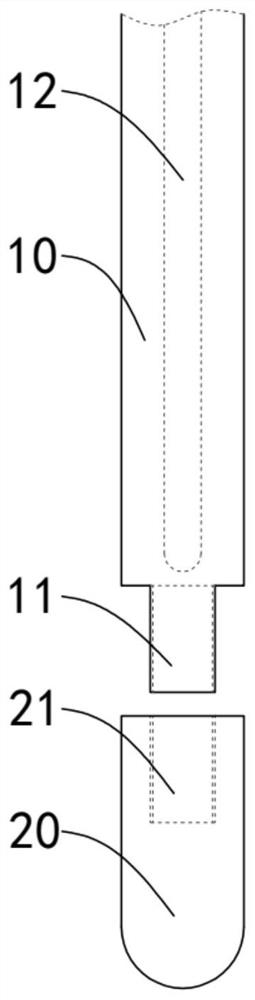

[0042] see figure 1 , the embodiment of the present invention also provides a method for preparing a quartz crucible without bubbles on the inner surface, using a combined gas-conducting graphite electrode, comprising the following steps:

[0043] Step 1, forming the quartz sand raw material into the inner wall of the graphite crucible to form a quartz crucible, installing a combined gas-conducting graphite electrode, and connecting the upper graphite electrode 10 and the lower graphite electrode 20;

[0044] Step 2: use the lower section graphite electrode 20 to strike the arc and heat the quartz crucible to melt the quartz crucible, and pass the protective gas into the axial air hole 12. The pressure of the protective gas is controlled at 0.2-0.7Mpa, so that The protective gas of the upper graphite electrode 10 passes through the inner wall side of the upper graphite electrode 10 to the outer wall side of the upper graphite electrode 10, and forms a 360 ° surrounding air flo...

Embodiment 1

[0049] Example 1: Taking the melting of a 32-inch quartz crucible as an example, three conventional graphite electrodes with a diameter of 65 mm are used for melting. After the melting is completed, the longitudinal length of the electrode head without silica vapor condensate is measured, and 50 sets of data are continuously measured. Take L from 50 sets of data min 85mm is used as the design length of the lower dense electrode. Combined gas-conducting graphite electrodes are used, the diameter of the upper graphite electrode 10 and the lower graphite electrode 20 is φ65mm, the length of the upper graphite electrode 10 is 600mm, the diameter of the axial pores 12 is φ12mm, and the through-hole porosity of the lower graphite electrode 20 is 30%~ 35%, the ash content of the upper graphite electrode 10 is 0.03%, the length of the lower graphite electrode 20 is 85mm, and the density of the lower graphite electrode 20 is 1.74g / cm 3 , the ash content of the lower graphite electrode...

Embodiment 2

[0051] Embodiment 2: Taking the melting of a 32-inch quartz crucible as an example, three conventional graphite electrodes with a diameter of 60 mm are used for melting. After the melting is completed, the longitudinal length of the electrode head without silica vapor condensate is measured, and 50 sets of data are continuously measured. Take L from 50 sets of data min 82mm is used as the design length of the lower dense electrode. Combined gas-conducting graphite electrodes are used, the diameter of the upper graphite electrode 10 and the lower graphite electrode 20 is φ60mm, the length of the upper graphite electrode 10 is 600mm, the diameter of the axial pores 12 is φ10mm, and the through-hole porosity of the lower graphite electrode 20 is 20%~ 30%, the ash content of the upper graphite electrode 10 is 0.03%, the length of the lower graphite electrode 20 is 82mm, and the density of the lower graphite electrode 20 is 1.74g / cm 3 , the ash content of the lower graphite electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com