Water pump and vehicle

A technology of water pumps and hydraulic components, applied in the field of vehicles, can solve the problems of increasing the axial space of the whole machine, wasting axial space, and rising costs, and achieve the effects of improving cooling uniformity, cooling efficiency, and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

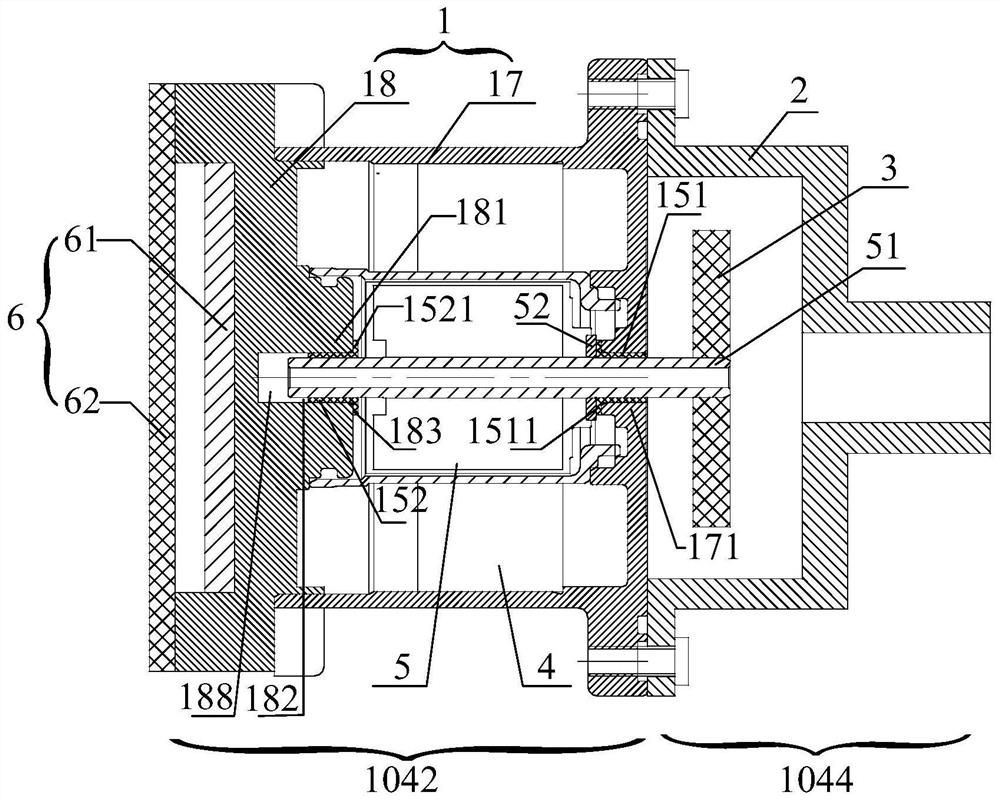

Embodiment 1

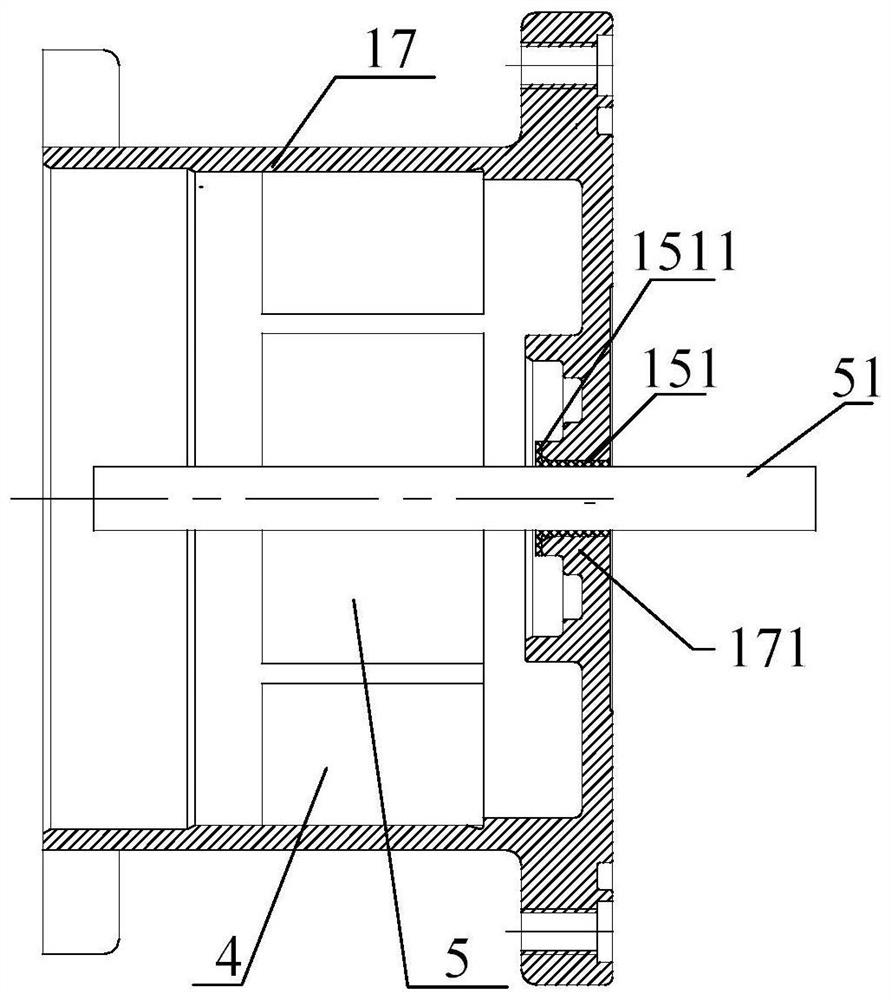

[0137] The limiting structure 34 includes: at least one first block 341, such as Figure 5 and Figure 6 shown. One end of the first stopper 341 is connected to the end surface of the rotor, and the other end of the first stopper 341 is provided with a stopper protrusion 3432, and the stopper protrusion 3432 is configured as a buckle 3411, such as Figure 5 shown. The buckle 3411 is used to stop and fit with the end of the washer 52 away from the rotor.

[0138] The buckle 3411 of the first stopper 341 is arranged at the end of the first stopper 341 far away from the rotor, and is used to resist and cooperate with the end of the washer 52 away from the rotor, so that the washer 52 is clamped between the elastic support member 35 and the buckle 3411 In between, under the blocking of the buckle 3411, the gasket 52 cannot cross the buckle 3411 in the axial direction, thereby restricting the axial position of the gasket 52, and when the gasket 52 is impacted by the first bearin...

Embodiment 2

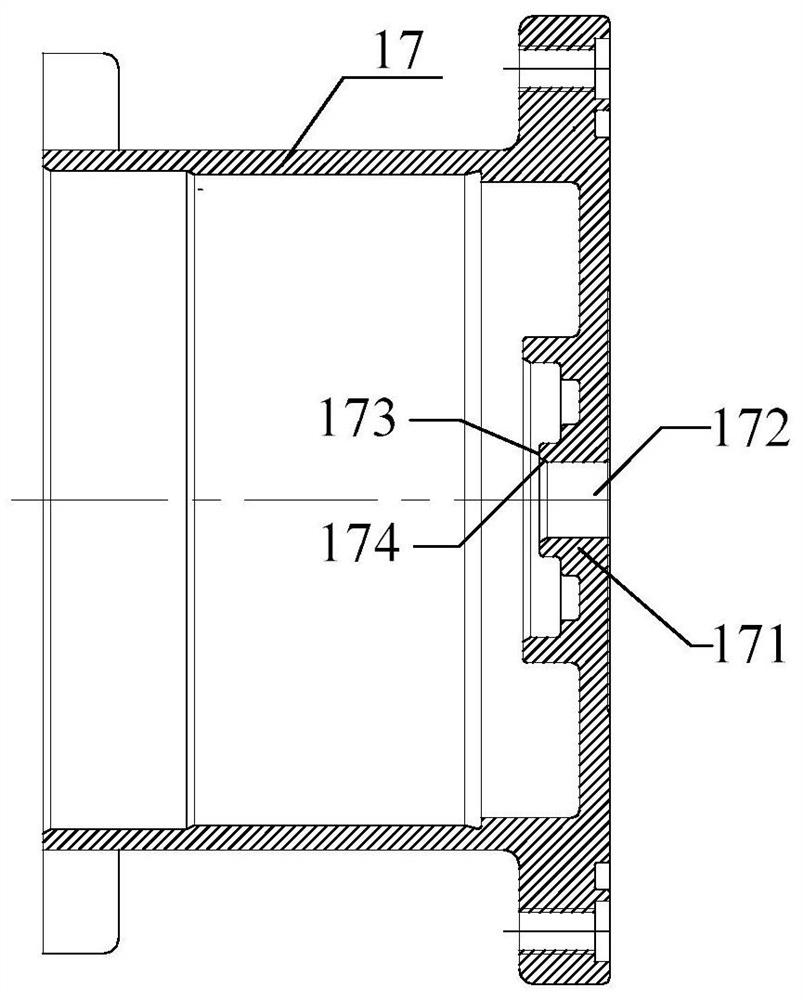

[0148] The limiting structure 34 includes: an annular limiting part 343, such as Figure 7 shown. One end of the annular limiting portion 343 is connected to the end surface of the rotor, and the other end of the annular limiting portion 343 is provided with at least one stop protrusion 3432, such as Figure 7 As shown, the annular limiting portion 343 is sleeved on the outside of the washer 52 .

[0149] The stop protrusion 3432 is provided at the end of the annular limiting portion 343 away from the rotor, and is used to stop and cooperate with the end of the washer 52 away from the rotor, so that the washer 52 is clamped between the elastic support member 35 and the stop protrusion 3432 During this period, under the blocking of the stop protrusion 3432, the gasket 52 cannot cross the stop protrusion 3432 in the axial direction, thereby restricting the axial position of the gasket 52, and when the gasket 52 is supported by the first bearing 151 During the impact, the gaske...

Embodiment 3

[0156] The limiting structure 34 includes: an annular limiting part 343, such as Figure 8 and Figure 9 shown. One end of the annular limiting portion 343 is connected to the end surface of the rotor, and the other end of the annular limiting portion 343 is provided with at least one stop protrusion 3432, such as Figure 8 As shown, the annular limiting portion 343 is sleeved on the outside of the washer 52 , and the stop protrusion 3432 is used to stop and fit with the end of the washer 52 away from the rotor 3 .

[0157] At the same time, the annular stopper 343 can also restrict the gasket 52 and the elastic support member 35 in the circumferential direction, which is beneficial to prevent the gasket 52 and the elastic support member 35 from radially shifting, tilting, etc., and further improves the padding performance. The stability and reliability of the sheet 52 and the elastic support 35.

[0158] Further, the annular limiting portion 343 is provided with an anti-ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com