Active anti-floating design method based on anti-floating variable water level

A design method and water level variable technology, applied in design optimization/simulation, infrastructure engineering, special data processing applications, etc., can solve problems such as increased construction costs, economic losses, poor groundwater runoff, etc., to achieve low construction costs and efficient construction Simple, technically feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

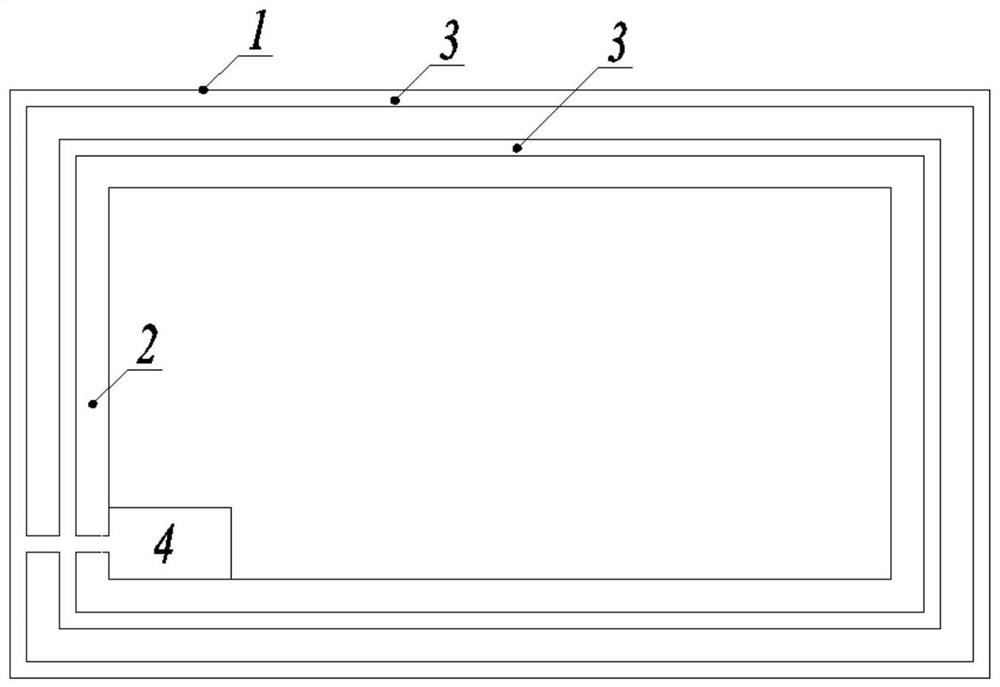

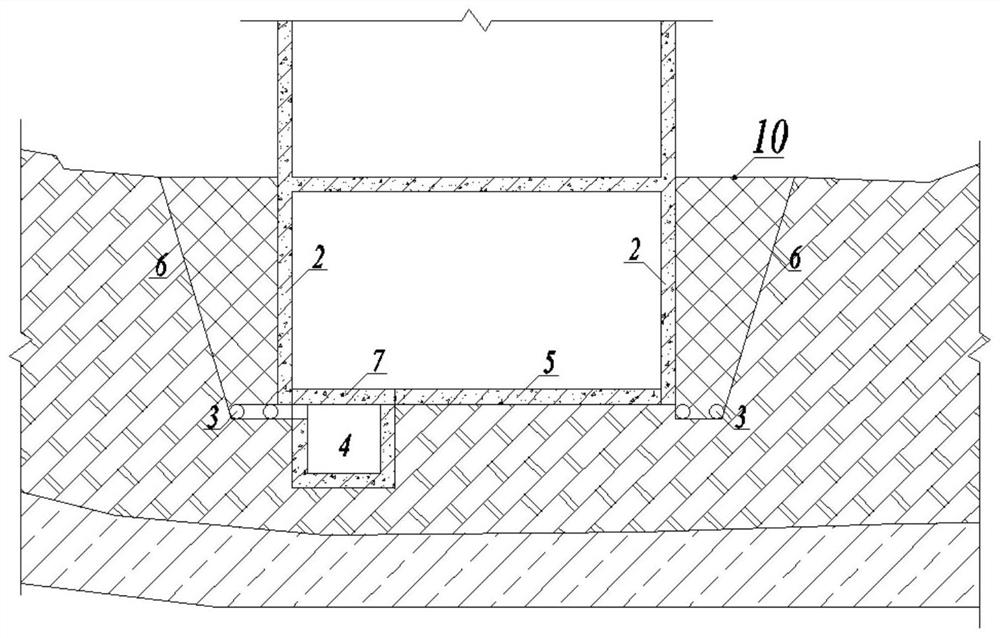

[0035] An active anti-floating design method based on anti-floating water level is suitable for such as figure 1 and figure 2 As shown in the drainage layout, after the excavation of the foundation pit is completed, the water collection well 4 will be built, and the reinforced concrete cover plate 7 will be installed in the water collection well. The drainage pipe 3 is arranged between them and its position is fixed. The drainage pipe 3 is connected with the water collection well 4, and the collected water in the water collection well 4 is discharged out of the basement through the pumping and drainage equipment; the basement floor 5 and the basement exterior wall 2 are poured, and finally the basement exterior wall 2 The foundation pit fertilizer groove between the foundation pit side wall 6 to the ground 10.

[0036] like Figure 5 As shown, the specific implementation process is as follows:

[0037] In step 1, when the underground water level of the construction site ri...

Embodiment 2

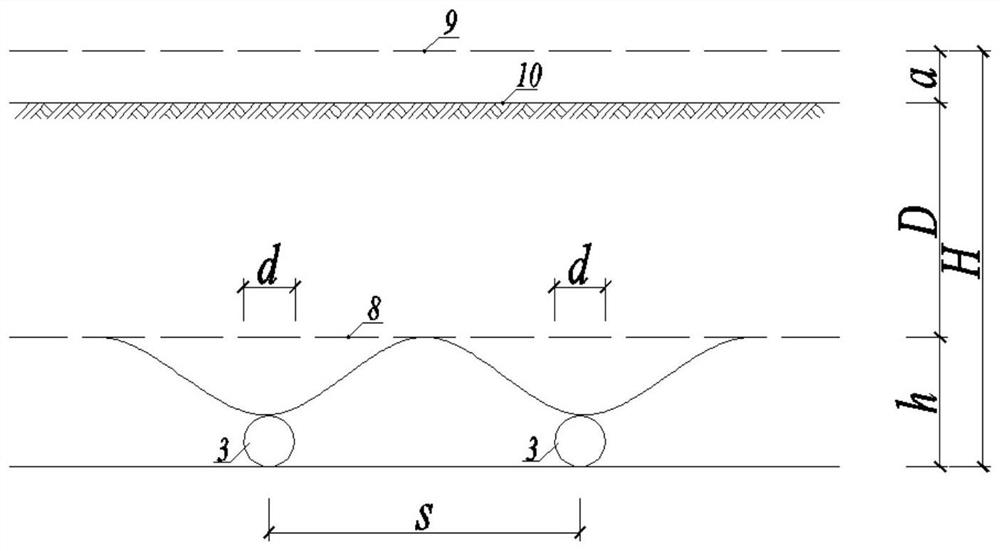

[0067] Step 1: Taking the bottom of the buried pipe as the benchmark, consider that the elevation of the anti-floating water level is H=26m, the anti-floating constant water level is h=5m, the seepage flow path D=20m, and the head difference Δh between the anti-floating water level and the anti-floating constant water level =21m, the width B of the fertilizer groove of the foundation pit at the constant water level against buoyancy 1 =5m, single pipe burial length (length of foundation pit) L=500m, soil permeability coefficient k=0.1m / s.

[0068] Substituting the parameters into formula 1.1 to obtain the hydraulic gradient between the anti-floating water level and the anti-floating constant water level:

[0069] Substitute the parameters into formula 1.2 to obtain the cross-sectional area at the constant water level: A 1 =B 1 L=5×500=2500m 2

[0070] Substitute the parameters into formula 1.3 to obtain the permeation flow at the constant water level against buoyancy: Q=k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com