Self-adaptive pressure control algorithm of reciprocating natural gas compressor

A technology of pressure control and natural gas, which is applied in the direction of pump control, electric controller, liquid variable capacity machinery, etc., and can solve the problem that the displacement of the compressor cannot be adjusted accurately and automatically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

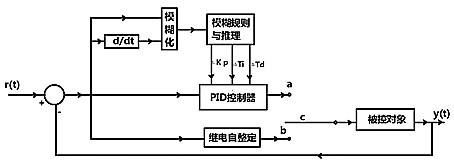

[0036] like Figures 1 to 6 shown, image 3 The whole algorithm sets two modes, self-tuning mode a and adjustment mode b. During the initial operation, turn switch c to the b self-tuning position, and obtain the initial value of the PID controller parameters through the parameter self-tuning module. This value can satisfy the Basic control requirements, the accuracy is slightly poor; in later use, switch the switch c to the adjustment mode position a, the PID controller will play a role, and the fuzzy control module will self-correct the PID parameters in real time to achieve the optimal control effect. The self-tuning module adopts the relay feedback tuning algorithm.

[0037] Most of the controlled systems can be equivalent to a first-order system with pure lag. By measuring the critical proportional gain Kc and oscillation period Tc of this first-order system, the parameters of the PID controller can be obtained according to the Z-N method formula. KP, Ti, Td.

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com