Revolving body scanning measurement method and data compensation calibration method thereof

A technology of data compensation and calibration method, applied in the field of laser scanning, can solve the problems of high work intensity, low efficiency, large errors, etc., and achieve the effect of reducing data, ensuring data, and reducing scanning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

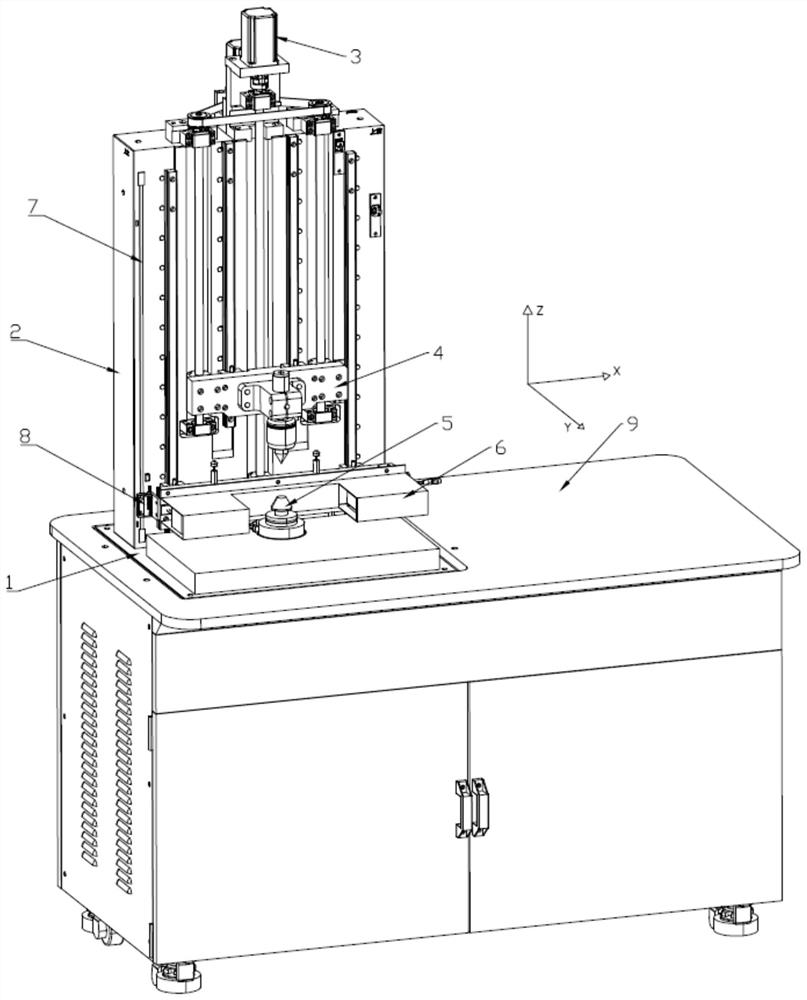

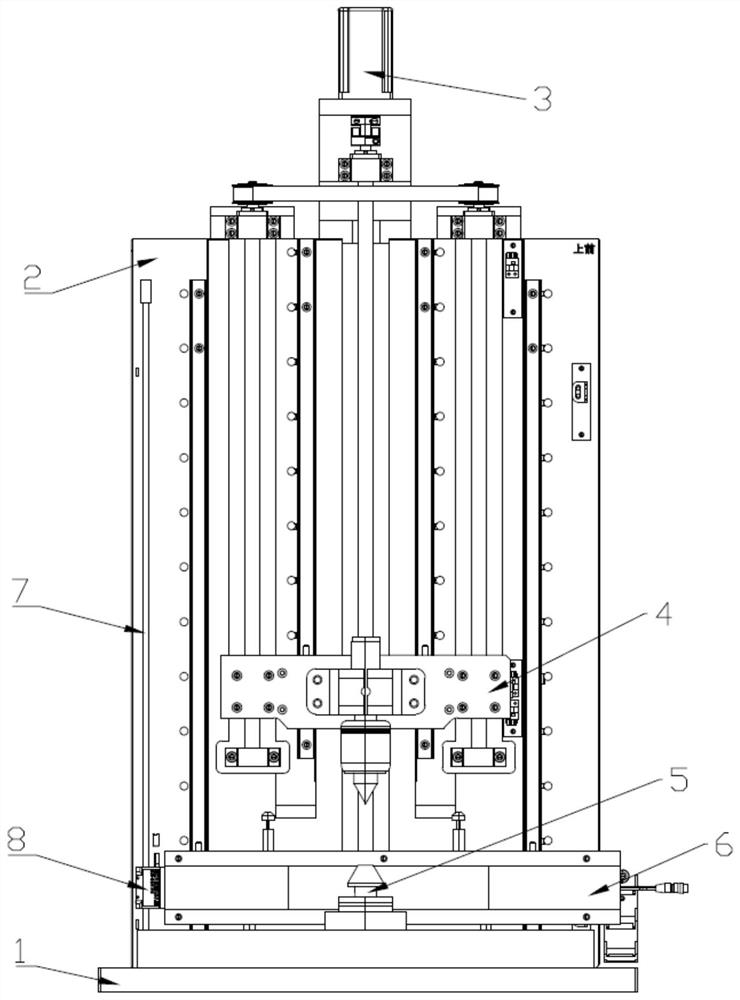

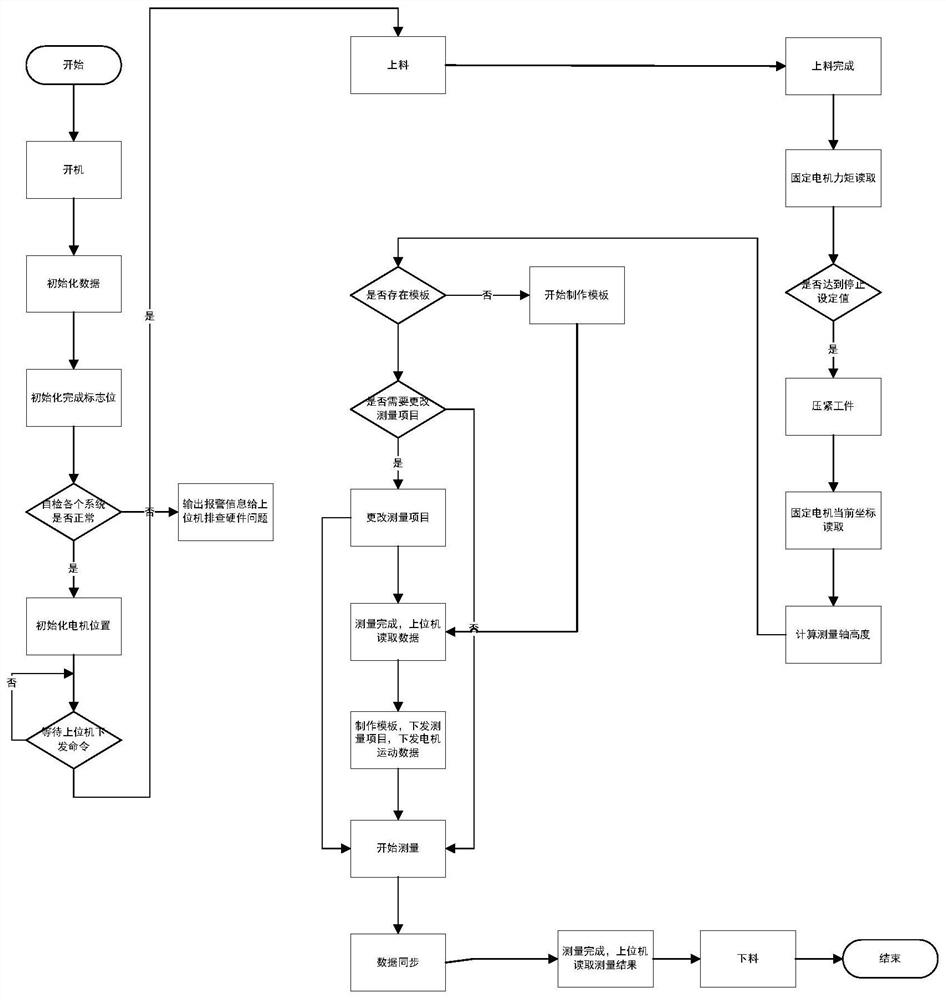

[0084] Such as figure 1 , 2 As shown, a high-precision rotating body measuring device includes a data processing device, a fixed table, a moving device 3, a positioning assembly, a scanning device 6 and a distance measuring device, wherein the moving device 3 is arranged on the fixed table; the positioning assembly is divided into two parts Parts are respectively arranged on the moving device 3 and the fixed platform, the positioning assembly is used to fix the revolving body; the scanning device 6 is arranged on the moving device 3; the distance measuring device is arranged on the fixed platform, and the distance measuring device is used to detect the scanning device 6 Traveling distance; the processing device is respectively connected to the distance measuring device, the moving device 3 and the scanning device 6 through communication.

[0085] The fixed platform includes a base 1 and a stand 2, the stand 2 is vertically arranged on the base 1, and the stand 2 is a square m...

Embodiment 2

[0189] This embodiment is obtained based on Embodiment 1, wherein the relative position of the upper positioning cone and the lower positioning cone needs to be tilted and self-calibrated before step 1; the tilted self-calibration includes the following steps:

[0190] Step S1: The data processing device receives the corresponding instruction and enters the tilt self-calibration mode;

[0191] Step S2: The scanning device scans the standard calibration rod, combined with the distance measuring device, to obtain scanning data; the standard calibration rod is a rotating body with known shaft diameter and height data;

[0192] Step S3: The data processing device obtains the inclination angle α of the standard calibration rod in the Y-Z plane according to the scan data;

[0193] Step S4: Obtain the inclination angle β of the standard calibration rod in the X-Z plane according to the inclination angle α;

[0194] Step S5: Determine the relationship between the inclination angle α ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com