Dry ice sublimation cooling spray chamber device

A technology for cooling spray and spray cavity, which is used in household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of inability to achieve the thermal insulation effect of dry ice spray cooling system, inapplicability, etc., to improve spray cooling efficiency and save consumption. , reduce the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

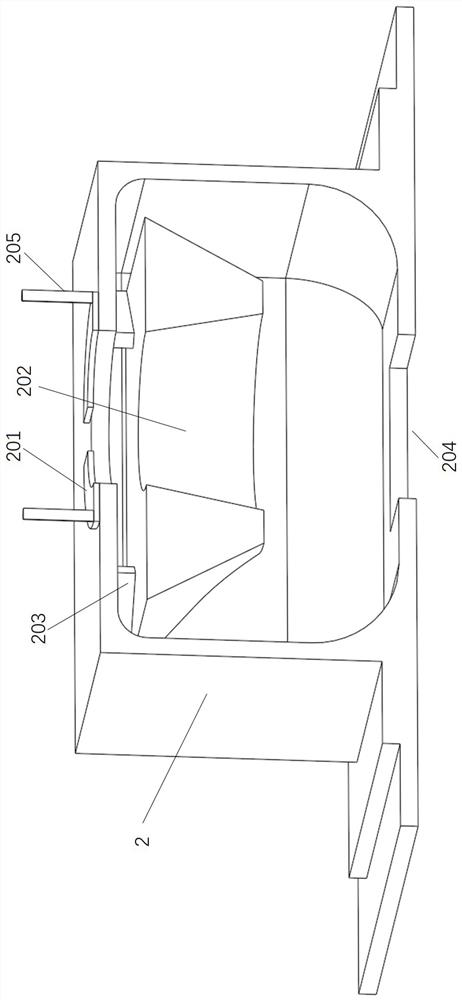

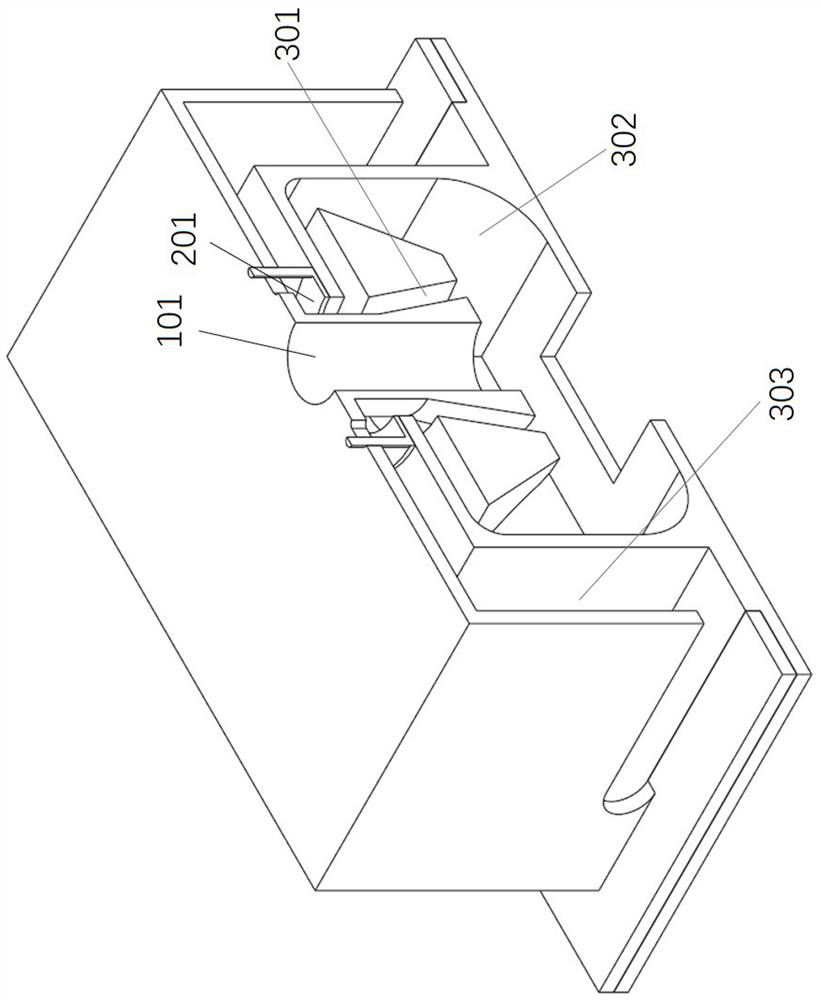

[0031] Such as Figure 1 to Figure 3 As shown, a dry ice sublimation cooling spray chamber device in this embodiment is composed of a dry ice spray chamber 2 and a thermal insulation shell 1 nested inside and outside. The surface level is tightly bonded.

[0032] The thermal insulation shell 1 is provided with a circular entrance, and the thermal insulation shell is provided with a nozzle tube 101 extending downward at the circular entrance. The cone-like outer contour; the dry ice nozzle enters the dry ice spray chamber through the circular inlet and the nozzle channel, the diameter of the nozzle channel is slightly larger than the diameter of the dry ice noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com