Bearing lubricating and cooling device for pitot tube pump

A bearing lubrication and cooling device technology, which is applied to components, pumps, and pump components of elastic fluid pumping devices, can solve problems such as low cooling efficiency, poor reliability, and mechanical failure, and meet the requirements of lubrication and Cooling effect, good stability, not easy to slip and fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0017] like figure 1 As shown, the specific embodiment of the present invention is:

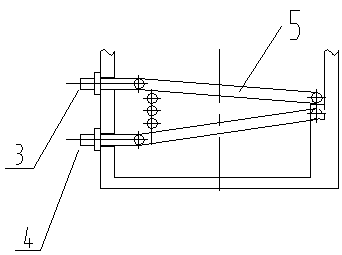

[0018] A bearing lubricating and cooling device for a pitot tube pump, comprising a bearing seat 1, a gland 2, a drive end and a non-drive end bearing housing, the bottom side of the bearing seat 1 is provided with a cooling inlet 3 and a cooling outlet 4, And a cooling pipe 5 is installed, the cooling pipe 5 is arranged in the lubricating oil in the bearing housing 6, the bearing lubrication efficiency is high, and the bearing operating temperature is low, the cooling pipe 5 flows axially and radially from the cooling inlet 3 to the cooling outlet 4 The paths are all in a high-to-low flow direction. The cooling outlet 4 is located at the lowest position of the flow path. The cooling inlet 3 and the cooling outlet 4 are designed to be high in and low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com