Magnetic suspension blower with adjustable blade tip clearance and debugging method

A technology of blade tip clearance and blower, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of volute adjustment, the inability of blade tip clearance to meet the requirements, and the inability to adjust the impeller and volute blade tip clearance, etc. To achieve the effect of improving the quality of the blast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

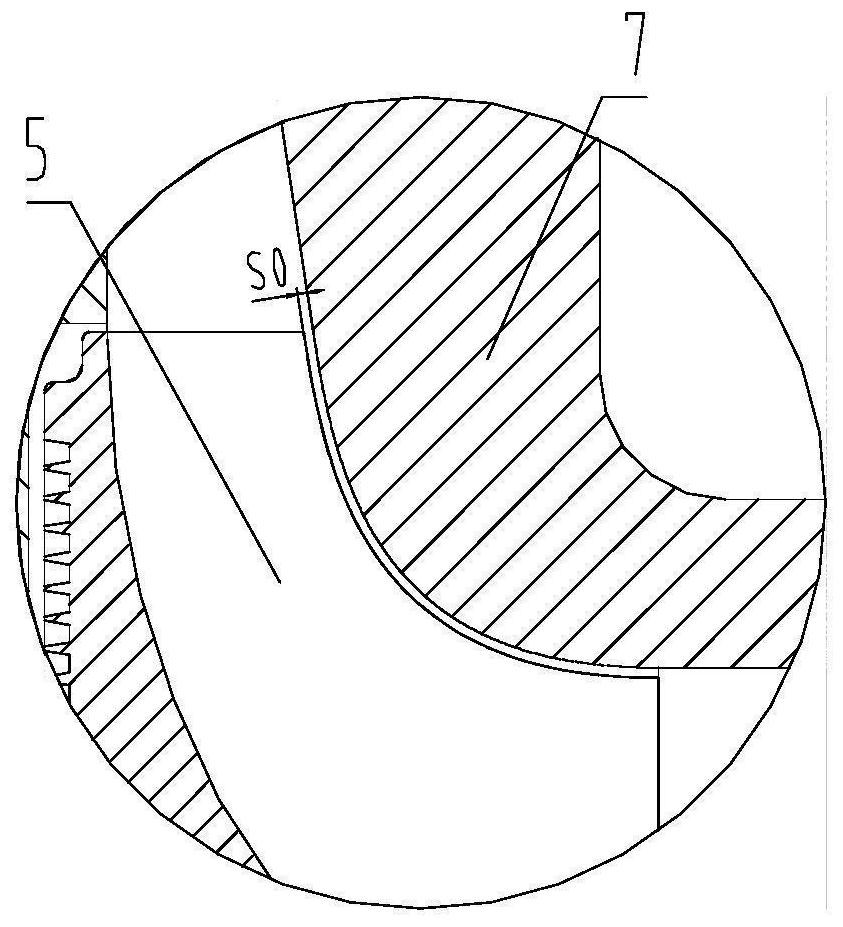

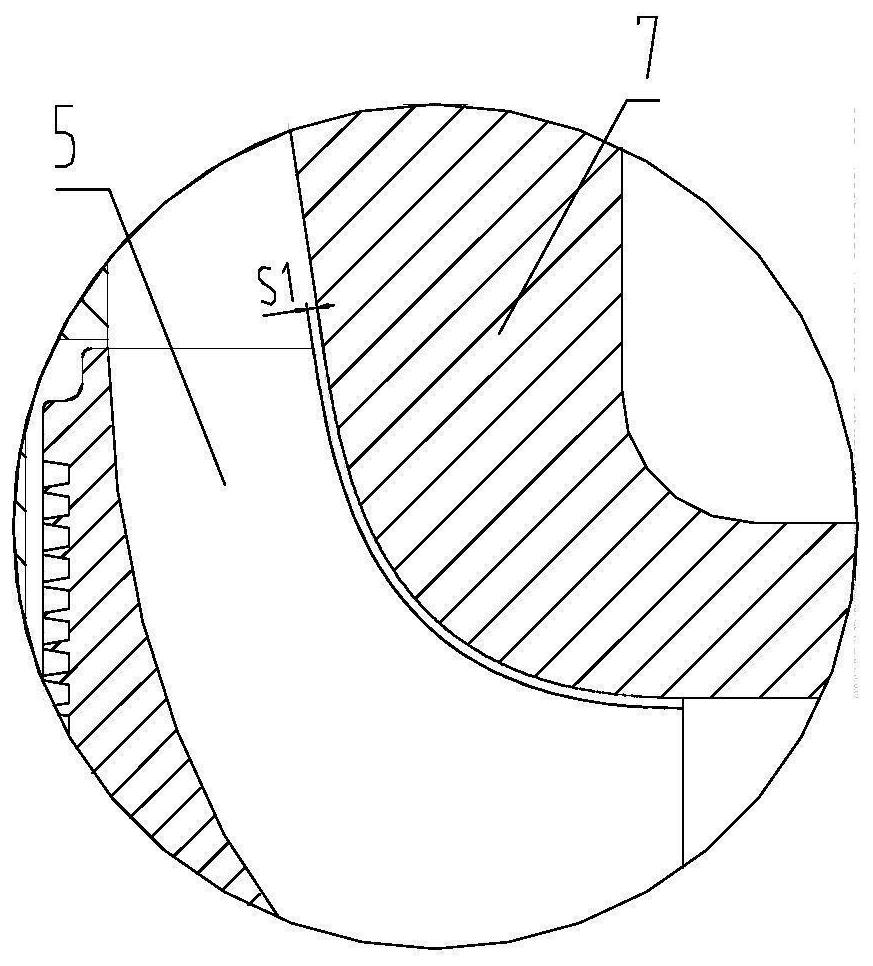

[0037] Such as figure 1Shown is a magnetic levitation blower with adjustable tip clearance, which includes a casing 1, a motor shaft 2, a magnetic bearing device 3, a plurality of radial and axial sensors 4, an impeller 5, an axial adjustment block 6 and a volute 7 ; The motor stator 11 is fixedly embedded in the inner hole of the casing 1, and the motor shaft 2 is fixedly provided with a motor rotor 21, and the position of the motor stator 11 corresponds to the position of the motor rotor 21; the impeller 5 is fixed on one end of the motor shaft 2, and the axial adjustment block 6 Fixed on the casing 1, the volute 7 is fixed on the axial adjustment block 6; the volute 7 is provided with a blast channel 71, and the impeller 5 is located in the blast channel 71; the axial adjustment block 6 is made of aluminum alloy, and the axial The adjustment block 6 is provided with a cooling water channel 61 and a resistance wire 62; the water inlet end and the water outlet end of the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com