Rapid hole plugging device for static breaking of pile head of cast-in-place pile and using method

A cast-in-place pile and pile head technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of accumulation, limit the application of static splitting technology, spray holes, etc., to ensure the quality of the project and improve the efficiency of pile head removal , the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

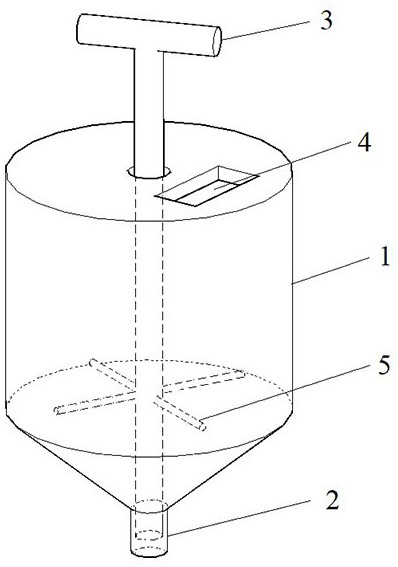

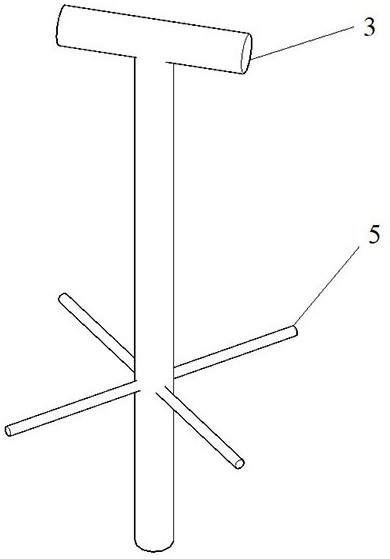

[0017] The fast hole plugging device for statically removing pile heads of cast-in-place piles is composed of a material storage tank (1), a material guide pipe (2), a stamping rod (3), and a material turning support (5). The material used for plugging holes is a mixture of rapid-setting cement and coarse sand. The rapid-setting cement quickly solidifies and achieves higher strength after being exposed to water. Adding coarse sand can increase the friction between the plugging material and the split hole wall, greatly improving Its plugging effect. The top of the storage tank (1) is provided with a square feeding hole (4) for filling hole-clogging materials, and the bottom is funnel-shaped. The feed pipe (2) is composed of a hollow steel pipe with an inner diameter of 50 mm and a length of 50 mm, and is connected to the bottom of the funnel surface of the storage tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com