Homogenization treatment process of S31254 super austenitic stainless steel

An austenitic stainless steel and homogenization treatment technology, which is applied in the field of metal forging, can solve the problems of not meeting the requirements of use and easy non-compatibility, etc., and achieve the effects of less time consumption, inhibition of growth, and guaranteed diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

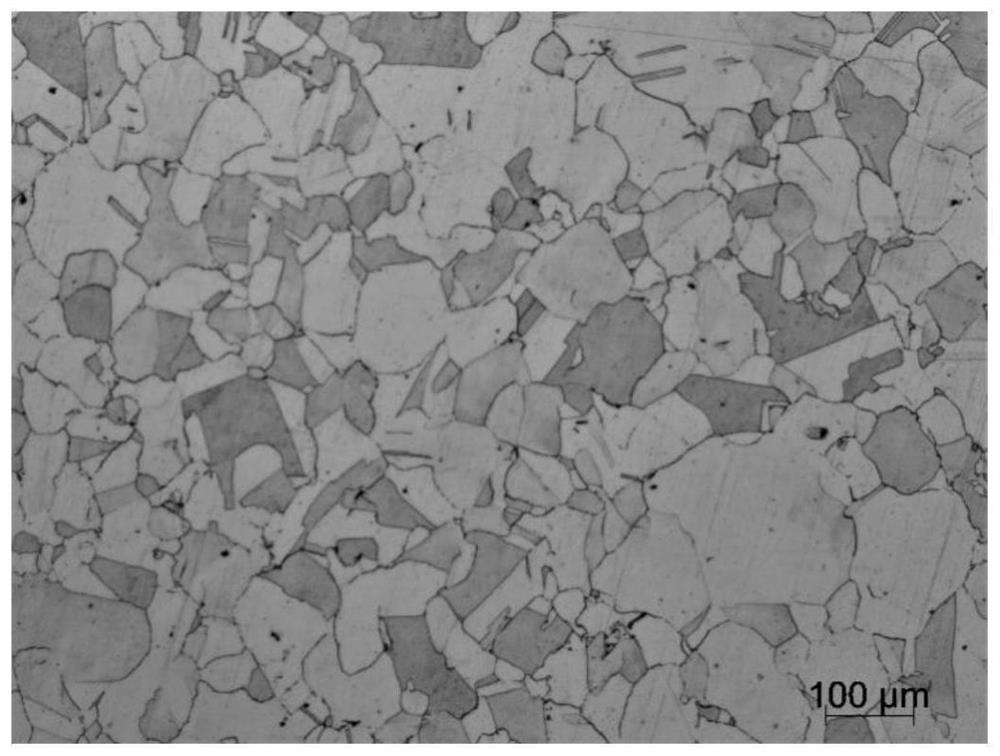

[0029] A homogenization treatment process for S31254 super austenitic stainless steel, specifically comprising the following steps:

[0030] Step 1: Heat a 19-inch S31254 steel ingot to 800°C and keep it warm for 2 hours to make the core temperature of the steel ingot consistent with the external temperature. The internal temperature is consistent with the external temperature, and the steel ingot is evenly heated through to obtain a heat-through steel ingot;

[0031] Step 2: Heat the heat-through steel ingot to 1260°C and keep it for 20 hours. After it is released from the furnace, the released steel ingot is obtained. Keep warm for 20 hours.

Embodiment 2

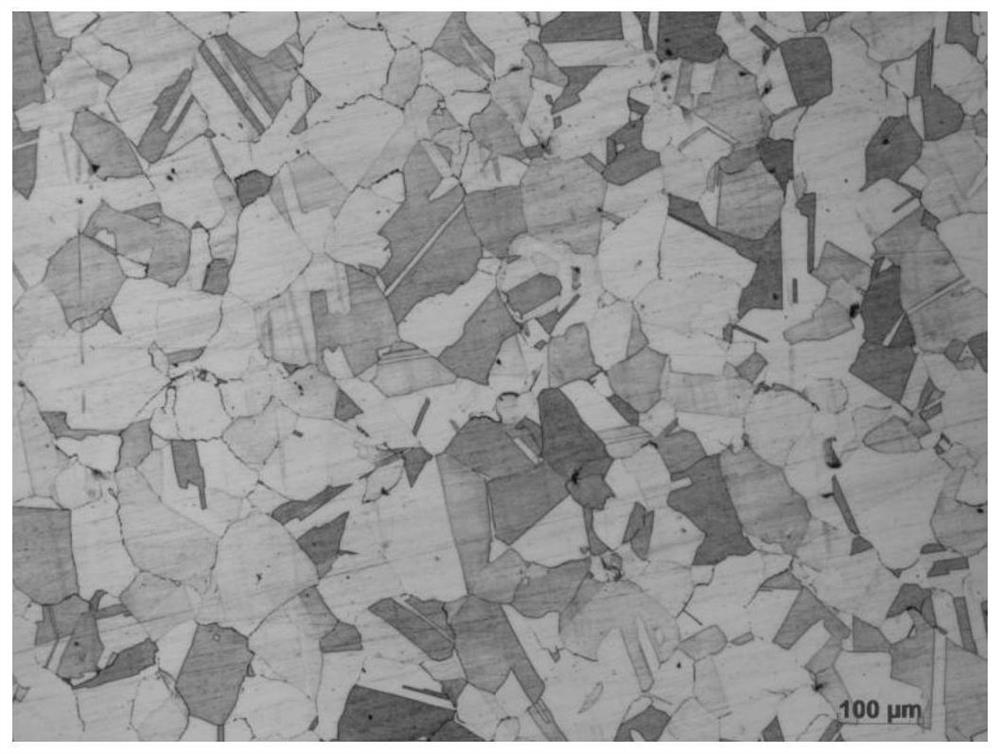

[0033] A homogenization treatment process for S31254 super austenitic stainless steel, specifically comprising the following steps:

[0034] Step 1: Heat a 19-inch S31254 steel ingot to 750°C, keep it warm for 2 hours to make the core temperature of the steel ingot consistent with the external temperature, and the steel ingot is evenly heated, then raise the temperature to 1150°C at a heating rate of 220°C / h, and hold it for 1.5 hours to make the steel ingot The core temperature is consistent with the external temperature, and the steel ingot is evenly heated through to obtain a heat-through steel ingot;

[0035] Step 2: Heat the heat-through steel ingot to 1260°C and keep it for 20 hours. After being released from the furnace, the discharged steel ingot is obtained. Keep warm for 18 hours.

Embodiment 3

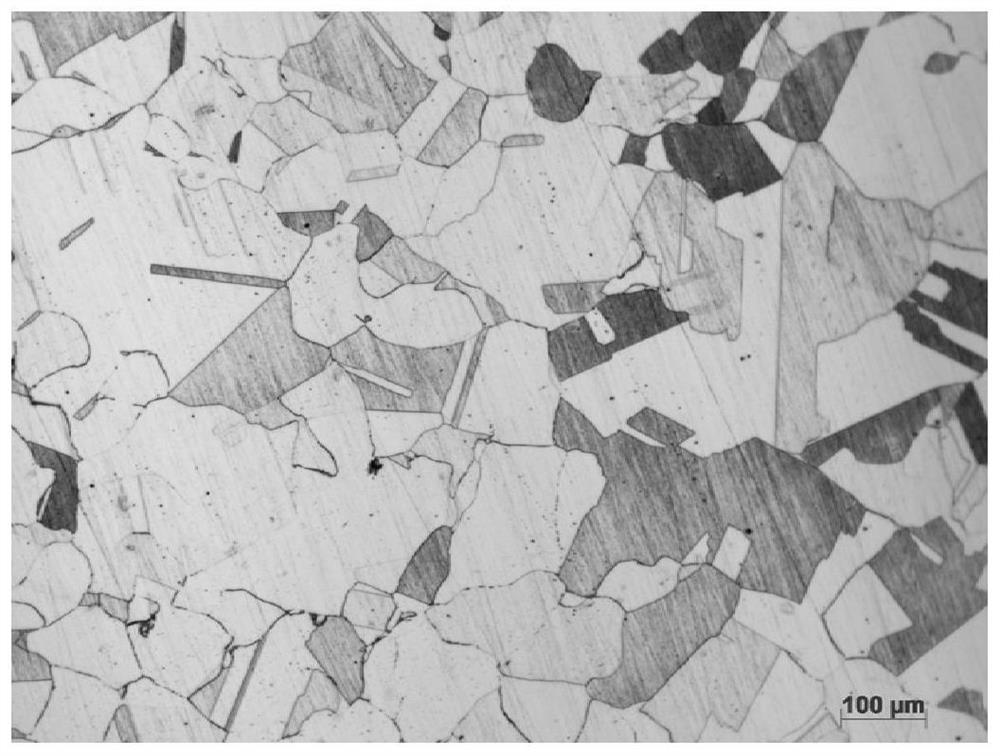

[0037] A homogenization treatment process for S31254 super austenitic stainless steel, specifically comprising the following steps:

[0038] Step 1: Heat a 12-inch S31254 steel ingot to 800°C and keep it warm for 1.5 hours to make the core temperature of the steel ingot consistent with the external temperature. The temperature of the core of the steel ingot is consistent with the external temperature, and the steel ingot is evenly heated through to obtain a heat-through steel ingot;

[0039] Step 2: Heat the heat-through steel ingot to 1240°C and keep it for 18 hours. After being released from the furnace, the discharged steel ingot is obtained. Keep warm for 18 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com