Method and production device for extracting ultra-pure helium from helium-containing natural gas at normal temperature in gradient manner

A natural gas and helium technology, applied in chemical instruments and methods, climate sustainability, inert gas compounds, etc., can solve problems such as narrow application range, high production energy consumption, and low yield of helium products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

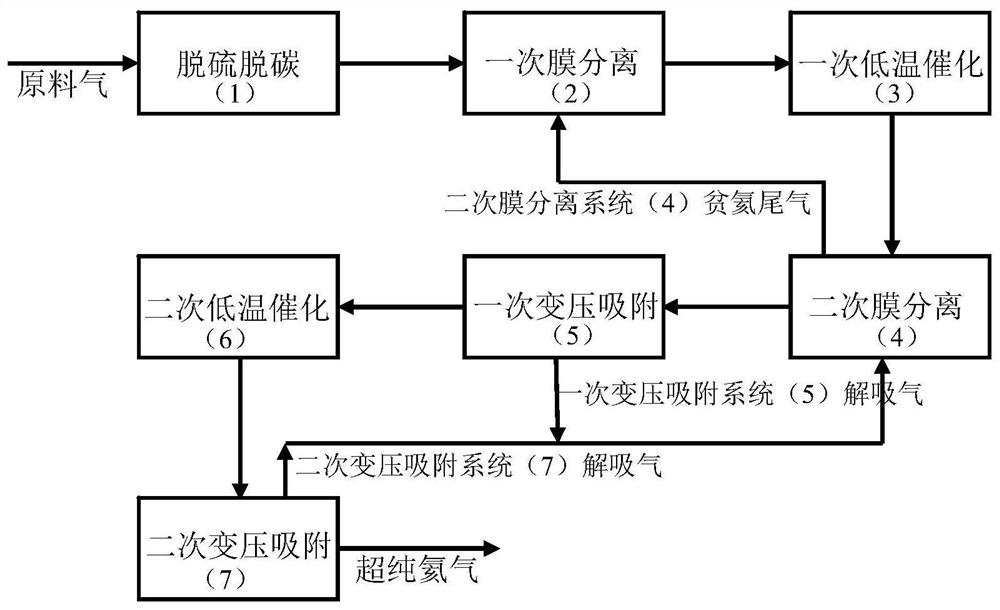

[0021] Please refer to the attached figure 1 . This figure embodies the main equipment of the present invention and its interconnection.

[0022] Helium-containing raw material gas 1 enters the primary membrane separation system (2) after being treated by the desulfurization and decarbonization system (1). The operating pressure of the membrane module is 2.90MPag, and the operating temperature is 60°C. After being treated by the gas separation membrane, the helium-removed tail gas is sent out of the boundary, and the concentrated hydrogen-containing raw material gas is sent to the primary low-temperature catalytic system (3). The dehydrogenation raw material gas after dehydrogenation treatment by the primary low-temperature catalytic system is sent to the secondary membrane separation system (4). The operating pressure of the membrane module is 2.90MPag, and the operating temperature is 60°C. After being treated by the gas separation membrane, the helium-removed tail gas r...

Embodiment 2

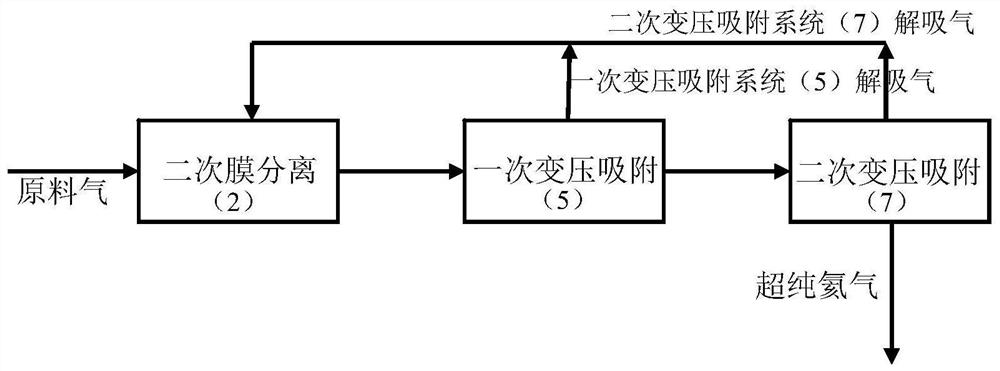

[0028] Please refer to the attached figure 2 . This figure embodies the main equipment of the present invention and its interconnection.

[0029] The helium-containing raw material gas 2 directly enters the secondary membrane separation system (4). The operating pressure of the membrane module is 6.90MPag, and the operating temperature is 70°C. After being treated by the gas separation membrane, the helium-removed tail gas is sent outside the boundary, and the raw material gas with high helium content is sent to the primary pressure swing adsorption system (5). The operating pressure of the pressure swing adsorption tower is 2.9MPag, and the operating temperature is 30°C. After treatment, the desorbed gas and the desorbed gas of the secondary pressure swing adsorption system (7) return to the secondary membrane separation system (4), and the helium concentration after the extraction reaches 99.9%, and enters the secondary pressure swing adsorption system (7 ), the operatin...

Embodiment 3

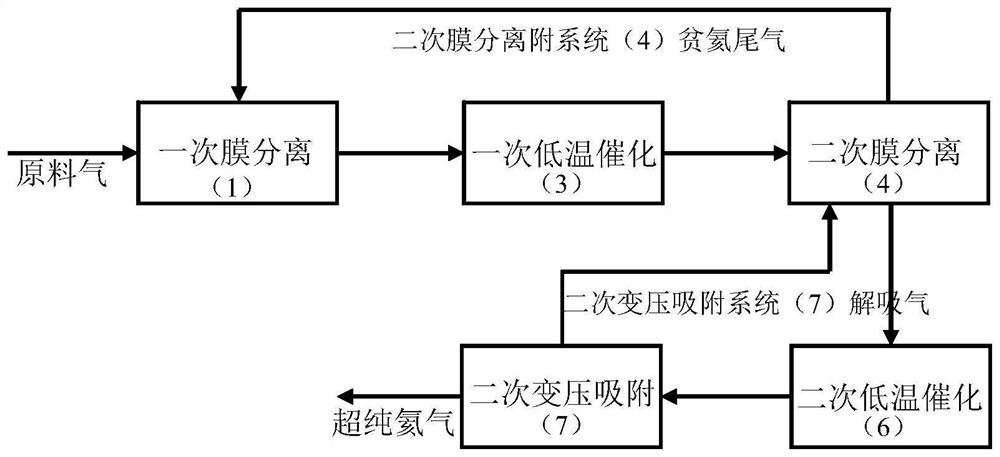

[0035] Please refer to the attached image 3 . This figure embodies the main equipment of the present invention and its interconnection.

[0036] The raw material gas containing helium enters the primary membrane separation system (2) directly. The operating pressure of the membrane module is 2.90MPag, and the operating temperature is 70°C. After being treated by the gas separation membrane, the helium-removed tail gas is sent out of the boundary, and the concentrated hydrogen-containing raw material gas is sent to the primary low-temperature catalytic system (3). The dehydrogenation raw material gas after the dehydrogenation treatment in the primary low-temperature catalytic system (3) is sent to the secondary membrane separation system (4). The operating pressure of the membrane module is 2.90 MPag, and the operating temperature is 70 °C. After being treated by the gas separation membrane, the helium-depleted tail gas is returned to the primary membrane separation system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com