Cutting device capable of conveniently adjusting cutting distance and used for constructional engineering

A technology of construction engineering and cutting device, applied in metal processing, manufacturing tools, metal processing equipment and other directions, can solve the problems of increased labor intensity of workers, prolonged construction period, low cutting efficiency, etc., and achieves reduced labor intensity of workers and shortened construction period. , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

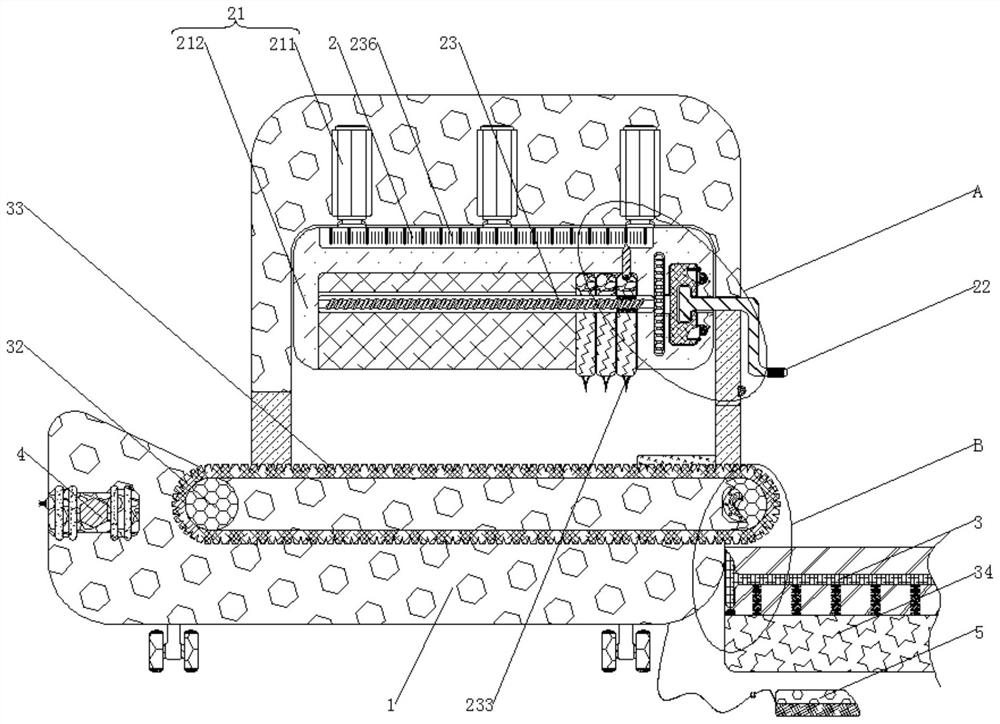

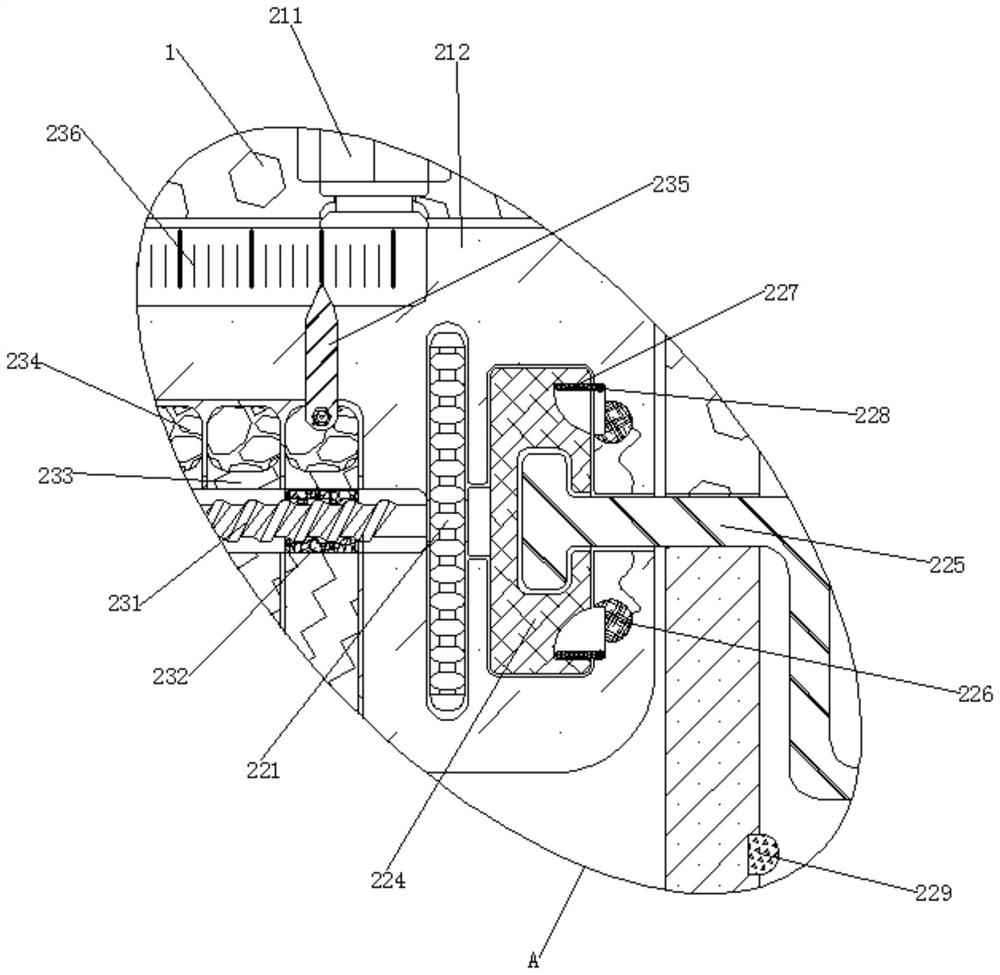

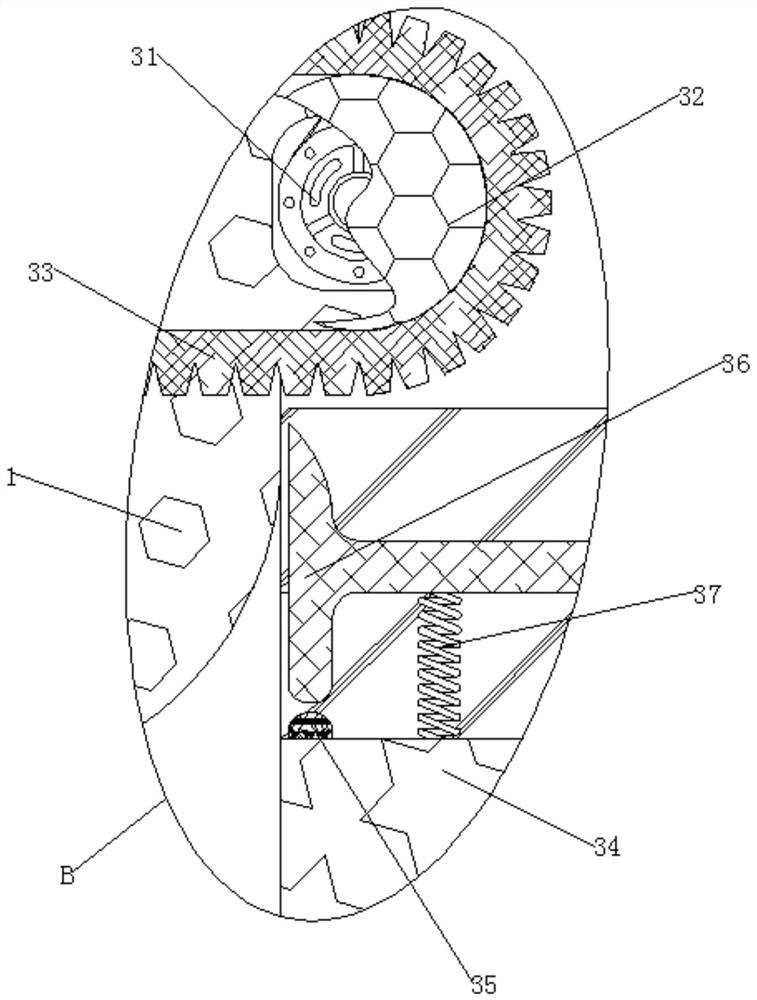

[0025] see figure 1 , 2 4. A cutting device for convenient adjustment of cutting spacing for construction engineering, comprising a casing 1, an adjustable cutting mechanism 2 is movably connected to the interior of the casing 1, and the adjustable cutting mechanism 2 includes an adjustment assembly 23, and the adjustment assembly 23 is adjusted for a speed change of the spacing. Assembly 22, push assembly 21 that pushes the adjustment assembly 23, the inner casing 1 is movably connected with the push assembly 21, and the push assembly 21 includes an electric telescopic rod 211, a push plate 212, and a chute 213, and the interior of the casing 1 is fixedly connected with an electric The telescopic rod 211 , the push plate 212 is fixedly connected to the outside of the electric telescopic rod 211 , the chute 213 is opened inside the push plate 212 , the push plate 212 is slidably connected to the inside of the housing 1 , and the speed change assembly 22 is movably connected to...

Embodiment 2

[0028] see Figure 1-4 , a cutting device that is convenient for adjusting the cutting spacing for construction engineering, comprising a casing 1, an adjusting cutting mechanism 2 is movably connected inside the casing 1, and the adjusting cutting mechanism 2 includes an adjusting assembly 23, and the adjusting assembly 23 is adjusted. , the push assembly 21 for pushing the adjustment assembly 23, the inside of the casing 1 is movably connected with the push assembly 21, the push assembly 21 includes an electric telescopic rod 211, a push plate 212, a chute 213, and the inside of the casing 1 is fixedly connected with an electric telescopic rod 211, the push plate 212 is fixedly connected to the outside of the electric telescopic rod 211, the chute 213 is opened inside the push plate 212, the push plate 212 is slidably connected to the inside of the housing 1, the speed change assembly 22 is movably connected to the inside of the push assembly 21, the speed change The assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com