Precision control tool for welding titanium alloy thin-wall winding drum

A technology of precision control and titanium alloy, applied in the field of titanium alloy welding, it can solve the problem of difficult high-precision control of deformation of thin-walled reels of titanium alloy, and achieve the effects of ultra-high-precision welding, convenient installation, and prevention of deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

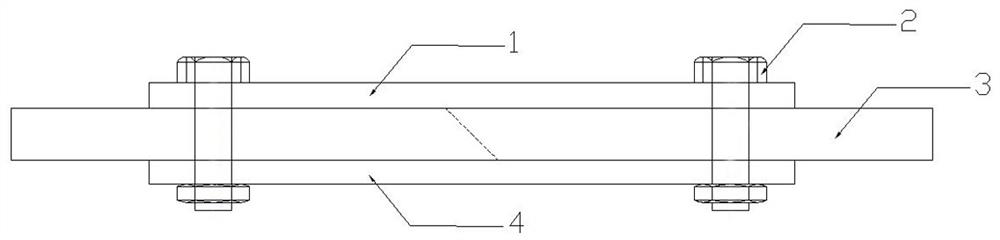

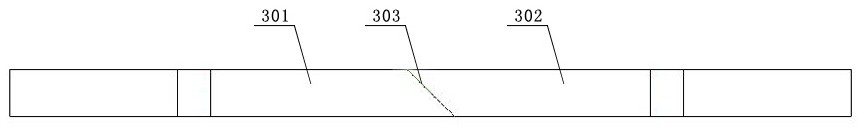

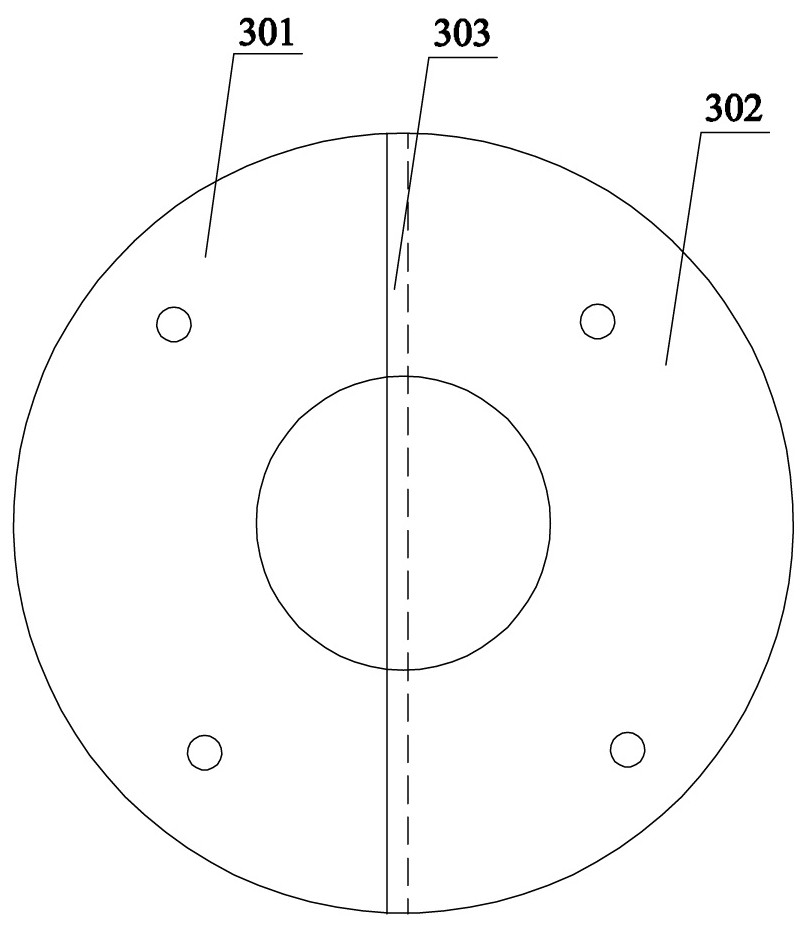

[0025] Such as Figure 1 to Figure 4 As shown, the precision control tooling for welding titanium alloy thin-walled rolls of this embodiment includes a clamping disc 3, which can be set according to different sizes of titanium alloy thin-walled rolls to be welded. Titanium alloy thin-walled reels are usually rolled into a cylindrical shape by titanium alloy thin plates, and are obtained by spot welding at the interface after curling. The clamping disc 3 is used to be sleeved in the thin-walled reel to be welded, along the The inner wall of the thin-walled reel is radially supported. In order to control the size of the thin-walled reel with high precision during welding, the clamping disc 3 includes a first disc body 301 and a second disc body 302, and the first disc body 301 and the second disc body 302. The two discs 302 are assembled together through the inclined surface 303 to form the clamping disc 3, that is, the first disc 301 and the second disc 302 can be two semicircu...

Embodiment 2

[0029] Different from Embodiment 1, in this embodiment, the inclined surface 303 and the axis of the clamping disc 3 form an included angle of 40°-50°, and the included angle is preferably 45°, because the inclined surface 303 of this angle makes the first disc body 301 When the second disc body 302 is subjected to axial pressure along the clamping disc 3, the relative displacement change can occur more stably, which is conducive to the stable dimensional change of the clamping disc 3 in the radial direction, and effectively avoids the first disc The body 301 and the second disk body 302 have a misalignment phenomenon.

Embodiment 3

[0031] The difference from the above-mentioned embodiment is that the materials used in the precision control tool for welding titanium alloy thin-walled drums in this embodiment are carefully selected materials, and the clamping disc 3 is made of a material with a higher thermal expansion coefficient than the titanium alloy. The coefficient of thermal expansion is slightly higher than that of titanium alloy.

[0032] The diameter tolerance of the finished titanium alloy reel is required to be within 0.5mm. In order to accurately control the dimensional accuracy, a material with a thermal expansion coefficient slightly higher than that of the titanium alloy is selected to make the clamping disc 3 after calculation. The thermal expansion coefficient of the titanium alloy is about 9×10 -6 / °C, the present invention selects 45# steel to make clamping disc 3, and the coefficient of thermal expansion of 45# steel is about 1.2×10 -5 / °C, after the titanium alloy thin-walled reel is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com