Inverse opal hydrogel microcarrier for treating wounds and application of inverse opal hydrogel microcarrier

An inverse opal and microcarrier technology, applied in the field of biomedical materials, can solve the problems of poor water-solubility and poor water-solubility of retinoic acid, and achieve the effect of good scar removal, convenient use and improvement of wound scars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the preparation of inverse opal hydrogel microcarrier

[0030] An inverse opal hydrogel microcarrier, the preparation steps are as follows:

[0031] (1) Preparation of silica colloidal crystal template:

[0032] Select silicon dioxide particles with an average diameter of 200 nm, suspend them in absolute ethanol, vortex and ultrasonically disperse them in absolute ethanol, and prepare a silicon dioxide dispersion with a concentration of 2%. Insert the glass sheet vertically into the silica dispersion, and place it in a constant temperature and humidity box, and adjust the temperature in the box to 30 degrees Celsius and the humidity to 40%. With the evaporation of absolute ethanol, the silica particles are neatly arranged on the surface of the glass sheet, forming a silica colloidal crystal template.

[0033] (2) Preparation of inverse opal film microcarriers

[0034] First, the recipe for the inverse opal film is as follows:

[0035] Cyclodextrin 2g ...

Embodiment 2

[0047] Embodiment 2: Wound scar repair experiment

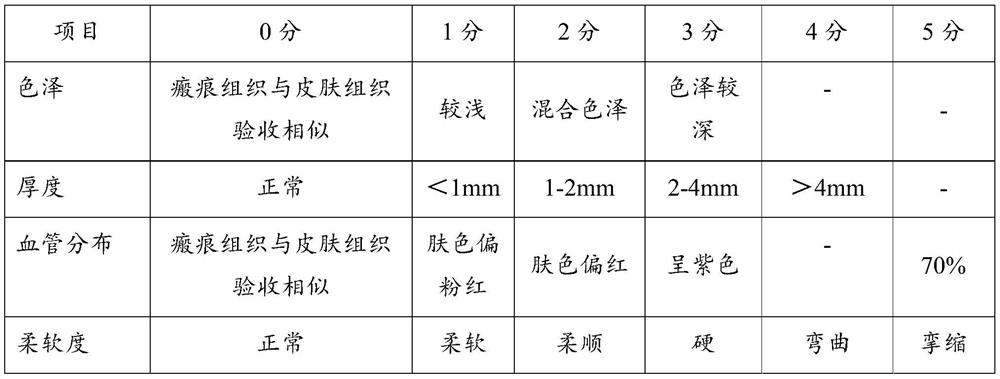

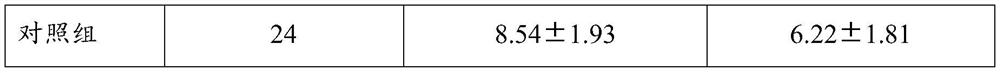

[0048] Methods: 18 large-eared white rabbits were purchased, male or female, with a body weight of 1.8-2.2kg. After adaptive feeding for 7 days, each white rabbit was observed, fed and watered, and there was no obvious abnormality, and they were included in the experiment. Establishment of scar animal model: anesthetized by injecting pentobarbital solution with a concentration of 30 g / L into the ear margin vein, and making a circular wound with a diameter of 1 cm on the ventral side of the rabbit ear along the long axis, two places in each ear, with an interval of about 3.0 cm, The full-thickness skin was completely removed, and the wound healed naturally after 21 days of skin transformation to form a hypertrophic scar mass. There was no unhealed wound infection or poor healing, and no new scar tissue was formed.

[0049] Grouping: 18 rabbits were randomly divided into 3 groups, namely blank group, experimental group and con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com