Cigar rolling machine

A cigar rolling and cigar rolling technology, which is applied in the manufacture of cigars, applications, tobacco, etc., can solve the problems of inconvenient maintenance, inflexible operation of the rolling machine, and fast adjustment, etc., and achieves easy maintenance, fast adjustment, and molding efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

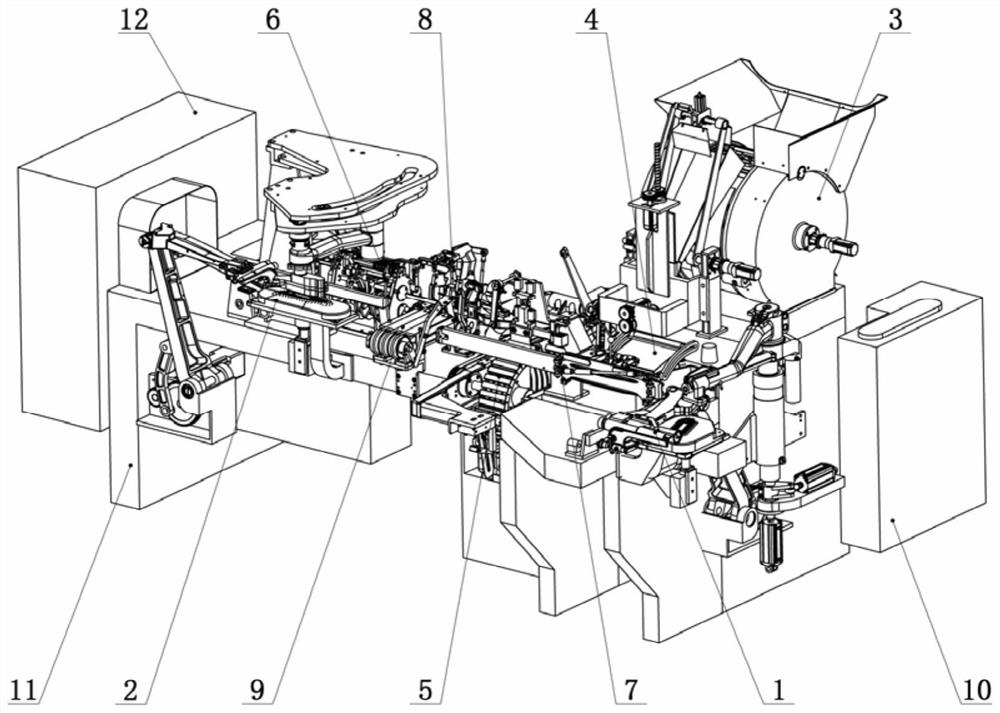

[0033] see Figure 1 to Figure 13, the present invention provides a technical solution: a cigar rolling machine, including twelve modular parts, the twelve modular parts are an inner bag cutting mechanism 1, an outer bag cutting mechanism 2, a core leaf supply mechanism 3, and a cigar rolling mechanism 4 , Sizing mechanism 5, wrapping assembly 6, inner wrapping conveying mechanism 7, outsourcing conveying mechanism 8, discharging conveying mechanism 9, negative pressure mechanism 10, frame 11, electric control system 12.

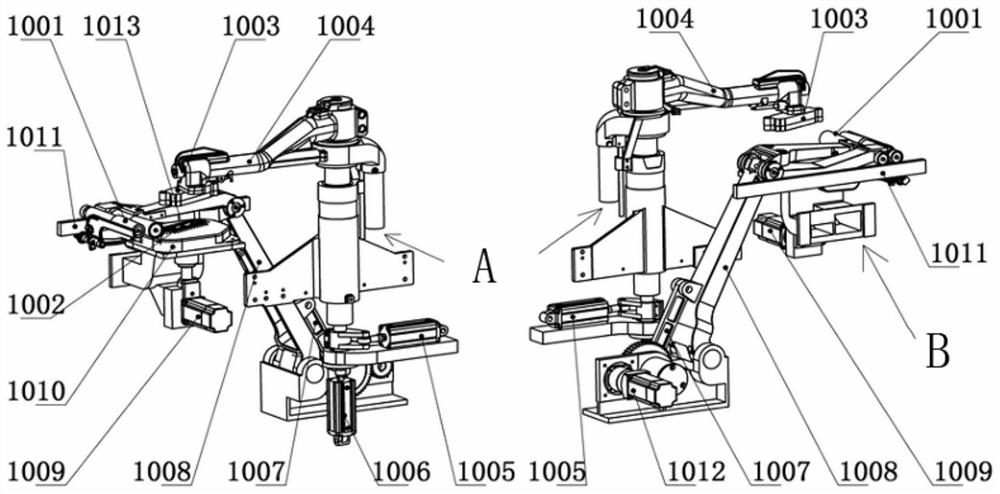

[0034] In this embodiment, the main component parts of the inner package cutting mechanism 1 include the first cutter roller 1001, the first knife mold 1002, the first suction cup 1003, the first suction cup swing arm 1004, the first suction cup swing cylinder 1005, the first suction cup Lifting cylinder 1006, first connecting rod 1007, second connecting rod 1008, first knife mold servo motor 1009, first knife mold base 1010, first cutter roller guide rail 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com