A real-time video seam cutting method and system based on microblaze

A real-time video and video technology, applied in image communication, selective content distribution, electrical components, etc., can solve the problems that the output of the display device cannot be well adapted, cannot meet the video seam clipping operation, and video distortion, etc. Convenient programming and debugging, real-time acquisition and processing of displayed images, and reduction of screen distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

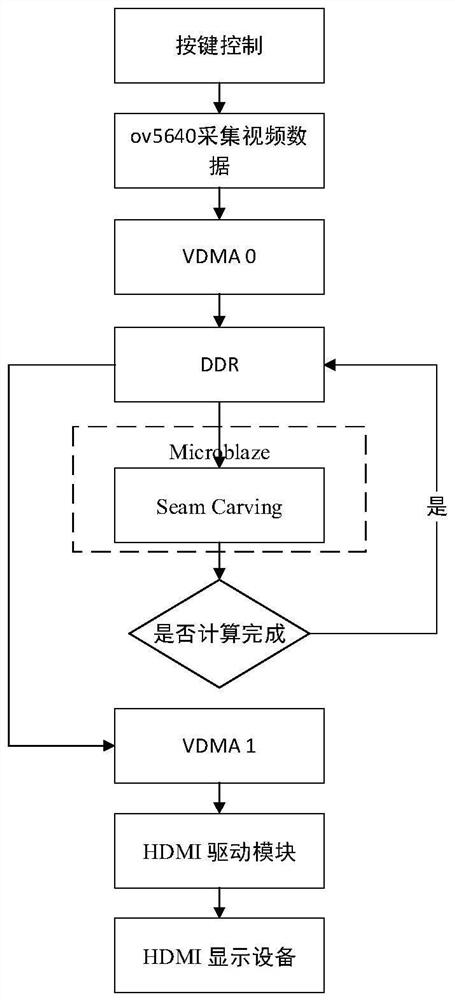

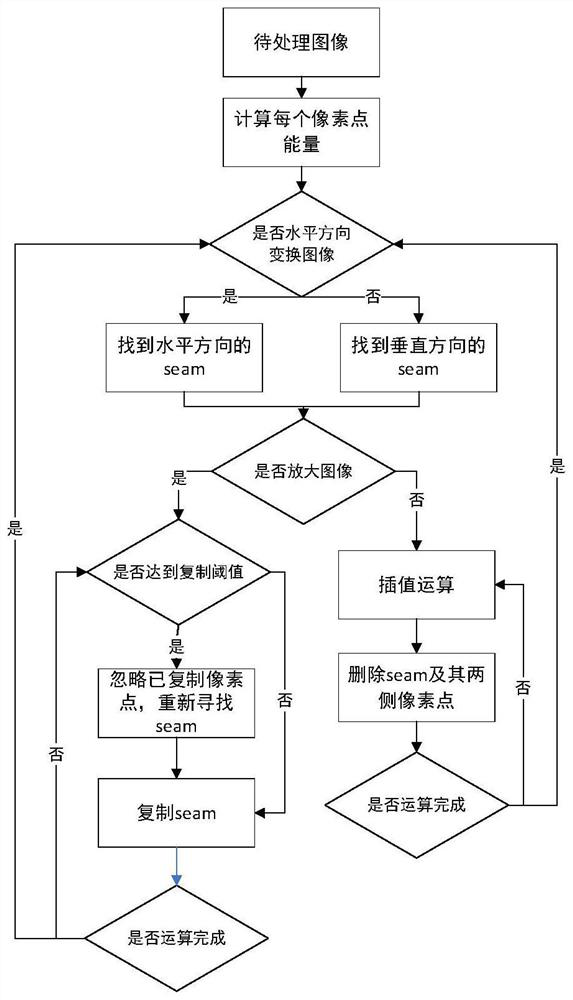

[0073] With the increasing demand for real-time video applications in public life, real-time video capture and display technology is widely used, especially in live broadcast, screen monitoring and other fields. In the prior art, for the transmission requirements of real-time video, data processing is often carried out by expanding or reducing the video, which often leads to the occurrence of video distortion; in addition, simply cutting the original video will cause information loss, Unable to perform real-time and undistorted seam cropping operations on video. In view of the situation that the input of the video capture device and the output of the display device cannot be adapted, this embodiment proposes a real-time video seam trimming method based on microblaze. In the case of looking for, improve the running speed and the rate of video information collection and transmission.

[0074] Specifically, a real-time video seam cropping method based on microblaze includes the ...

Embodiment 2

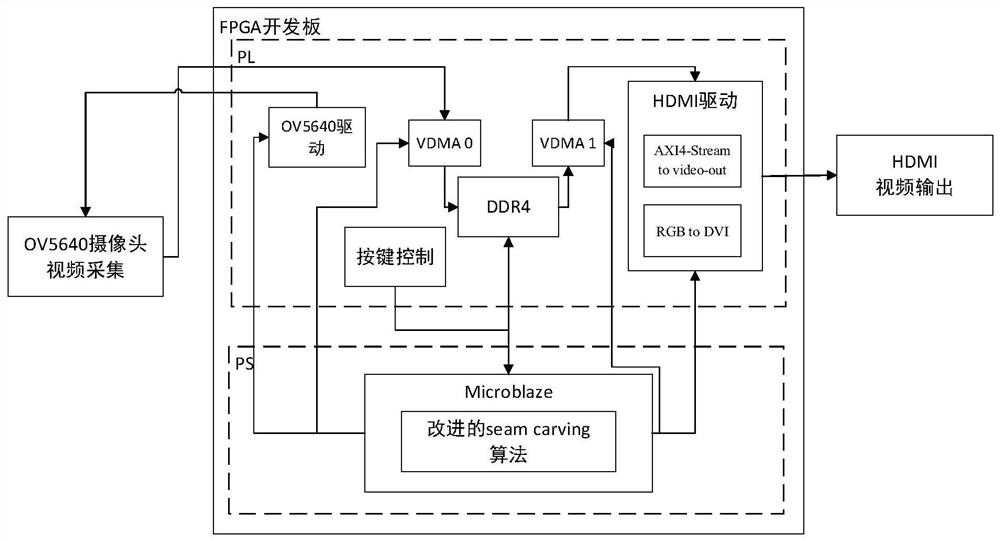

[0083] In a further embodiment based on the first embodiment, a real-time video seam cutting method based on microblaze is implemented by combining the PS system processing terminal and the PL programmable logic terminal.

[0084] Specifically, the processing end of the PS system is composed of the microblaze soft core module and the seam cutting algorithm module, which are responsible for the scheduling and control of the overall operation process, and provide a processing unit for realizing the video seam cutting operation process; the PL programmable logic end is composed of The camera video acquisition module, VDMA frame buffer module, DDR memory module, HDMI display module module, button control module are composed, which are responsible for the acquisition and display of video data. Both the PS system processing end and the PL programmable logic end can interact with the DDR double-rate synchronous dynamic random access memory to read or write data, and use the AXI bus to...

Embodiment 3

[0088] In a further embodiment based on the first embodiment, the camera video acquisition module selects the corresponding video acquisition resolution according to the trigger signal, and when acquiring the corresponding original video data, the selected camera is an OV5640 monocular camera. In a preferred embodiment, the preset The resolution of the captured video image is 640*480.

[0089] In order to facilitate the subsequent seam cropping operation on the video data, when reading the video data in the double-rate synchronous dynamic random access memory for processing and analysis, the microblaze soft core first performs RGB to grayscale processing on the video image data. The corresponding conversion formula for:

[0090]

[0091] In the formula, represents the image data after grayscale processing; Indicates the brightness value of the red channel; Indicates the brightness value of the green channel; Represents the luminance value of the blue channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com