Method and device for determining safe fracture toughness of pipeline

A fracture toughness and determination method technology, applied in the direction of applying stable tension/pressure to test material strength, complex mathematical operations, etc., to achieve accurate and reliable calculation results, accurate determination, simple and fast calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

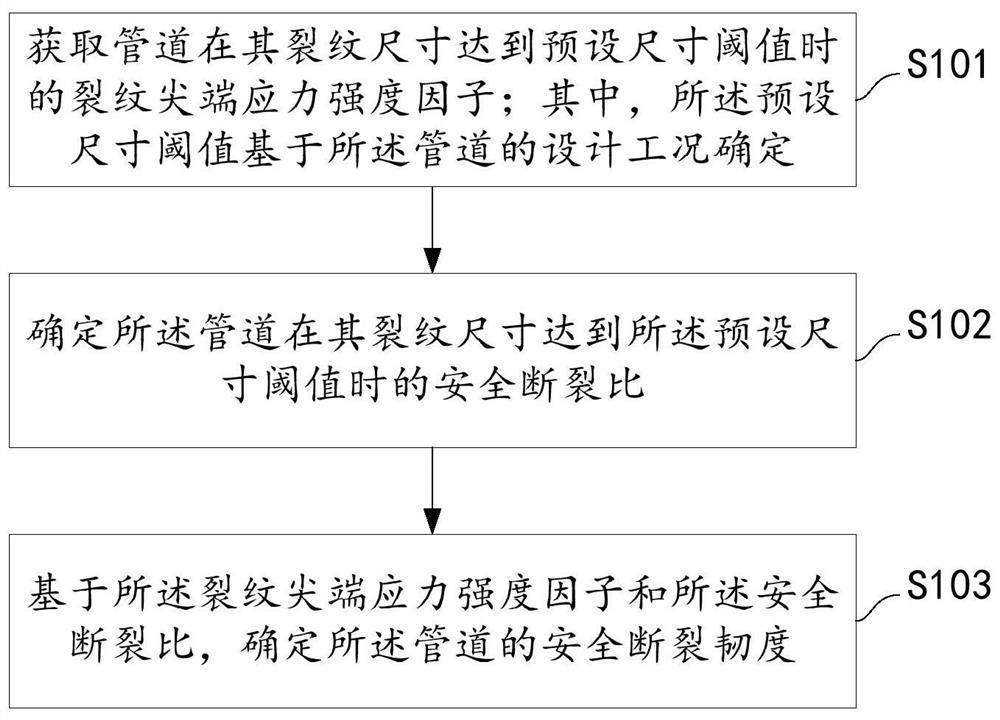

[0052] According to an embodiment of the present invention, a method for determining the safe fracture toughness of a pipeline is provided, such as figure 1 As shown, the method described in this embodiment includes:

[0053] Step S101, obtaining the crack tip stress intensity factor of the pipeline when the crack size reaches a preset size threshold; wherein the preset size threshold is determined based on the design working conditions of the pipeline;

[0054] In this embodiment, the design conditions of the pipeline include: the allowable wall thickness of the pipeline under preset corrosion conditions, the preset delivery pressure of the pipeline, etc., and the preset size threshold can be based on the preset Design parameters such as the allowable wall thickness under corrosive conditions and the preset delivery pressure of the pipeline are determined.

[0055] In this embodiment, the crack tip stress intensity factor of the pipeline when the crack size reaches a preset ...

Embodiment 2

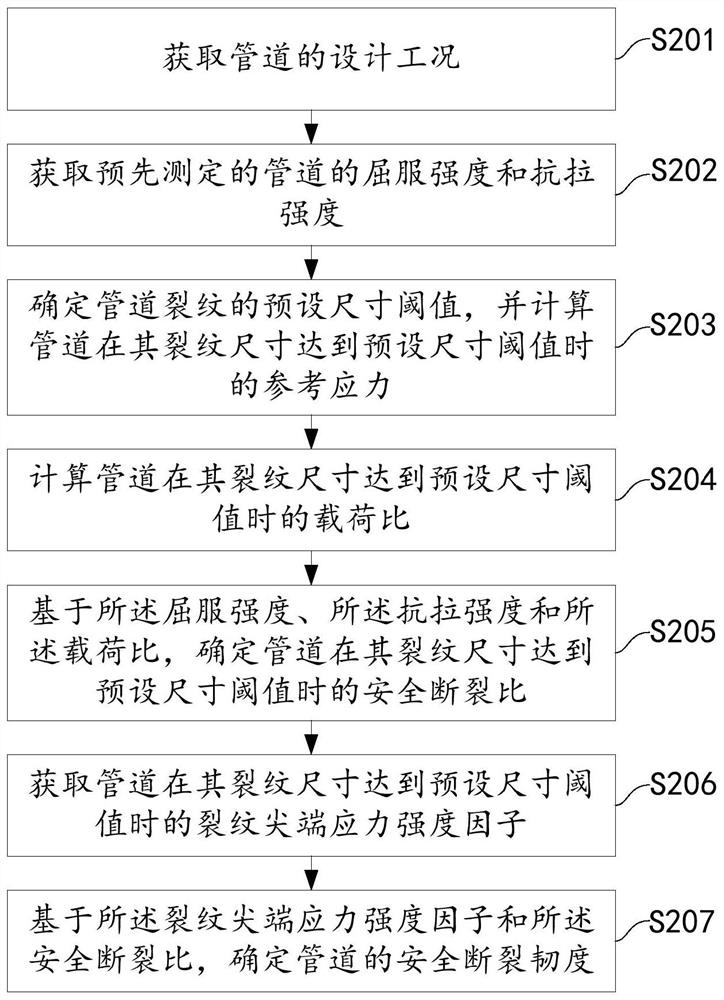

[0079] This embodiment takes an X80 natural gas transmission pipeline project with a specification of φ1219×21.4mm and a design pressure of 12MPa as an example to describe in detail the method for determining the safe fracture toughness of the pipeline project at the design stage. Such as figure 2 As shown, the method includes:

[0080] Step S201, obtaining the design working condition of the pipeline;

[0081] Specifically, a comprehensive analysis of pipeline corrosion conditions shows that the treated natural gas is less corrosive. According to the annual average corrosion rate of 0.1mm and the pipeline service for 30 years, the allowable wall thickness under pipeline corrosion conditions is 18.4mm. At the same time, the delivery pressure of the set pipeline is obtained.

[0082] Step S202, obtaining the pre-measured yield strength and tensile strength of the pipeline;

[0083] Specifically, the transverse tensile specimen of the pipeline is prepared according to the re...

Embodiment 3

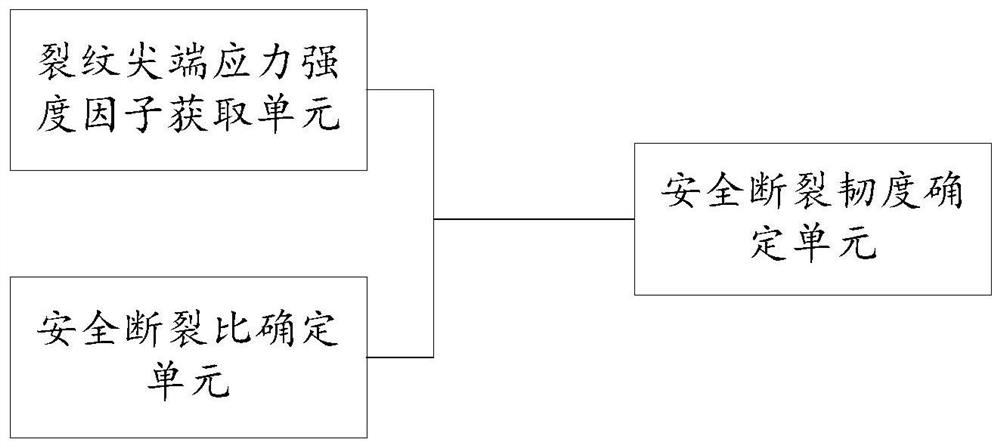

[0117] Corresponding to the above method embodiments, the present invention also provides a device for determining safe fracture toughness, such as image 3 As shown, the device includes:

[0118] The crack tip stress intensity factor acquisition unit 301 is configured to acquire the crack tip stress intensity factor of the pipeline when the crack size reaches a preset size threshold; wherein the preset size threshold is determined based on the design condition of the pipeline;

[0119] A safe fracture ratio determination unit 302, configured to determine the safe fracture ratio of the pipeline when the crack size reaches the preset size threshold;

[0120] The safe fracture toughness determination unit 303 is configured to determine the safe fracture toughness of the pipeline based on the crack tip stress intensity factor and the safe fracture ratio.

[0121] For details related to specific implementations such as the working principle and workflow of the above-mentioned dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com