Cooling and heat preservation assembly for high-temperature magnetic drive pump

A magnetic pump and assembly technology, which is applied in the field of cooling and thermal insulation assemblies for high-temperature magnetic pumps, can solve the problems of difficult welding, weak welding, and limited welding position of pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

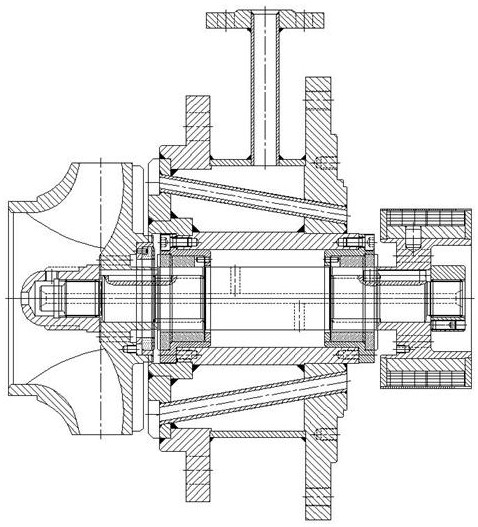

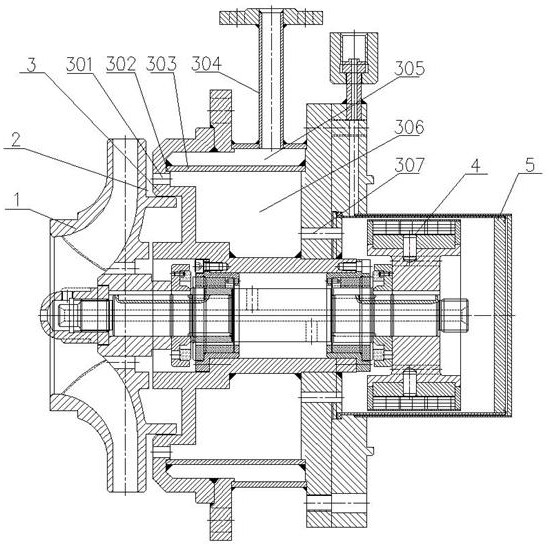

Image

Examples

Embodiment 1

[0027] The cooling and heat preservation assembly 3 is divided into a cooling and heat preservation inner chamber 305 and a drainage inner chamber 306 by a partition assembly 303 , and a plurality of first drainage holes 301 and second drainage holes 307 are evenly arranged in a ring in the drainage inner chamber 306 .

[0028] The above-mentioned technical solutions in the embodiments of the present application have at least the following technical effects or advantages:

[0029] Since the cooling and heat preservation assembly is separated into a cooling and heat preservation inner cavity and a drainage inner cavity by a partition plate assembly, and a number of first drainage holes and second drainage holes are uniformly arranged in a circular shape in the cooling and heat preservation inner cavity, the problem is effectively solved. In the prior art, the pipe is welded in the cooling and heat preservation assembly. Due to the limited position reserved in the cooling and hea...

Embodiment 2

[0031] The inner wall of the cooling and heat preservation assembly 3 is provided with an annular boss 302 , and the outer ring of the annular boss 302 is welded with a partition assembly 303 .

[0032] The above-mentioned technical solutions in the embodiments of the present application have at least the following technical effects or advantages:

[0033] Since the inner wall of the cooling and heat preservation assembly is equipped with an annular boss, the outer ring of the boss is welded with a partition assembly, and the cooling and heat preservation assembly is divided into a cooling and heat preservation inner cavity and a drainage inner cavity through the partition plate assembly, so it is effectively solved. In the prior art, the technical problem of heat preservation of the easily crystallized medium cannot be realized, and then realized that the high-temperature magnetic pump can be cooled or kept warm according to the different media, the water inlet of the high-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com