A device for cleaning the inner wall of the ventilation duct of a range hood

A technology for ventilation ducts and range hoods is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems of exhaust structure range hood failure, oil dripping, sticking and blocking, pollution and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

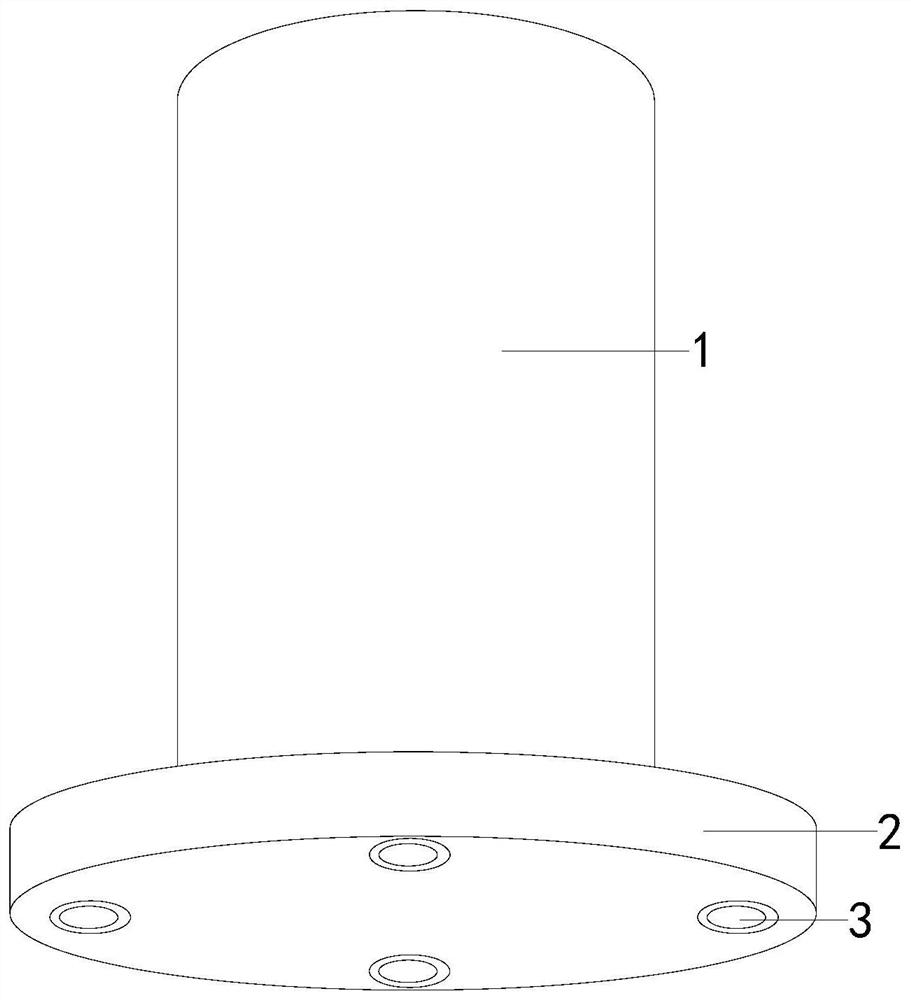

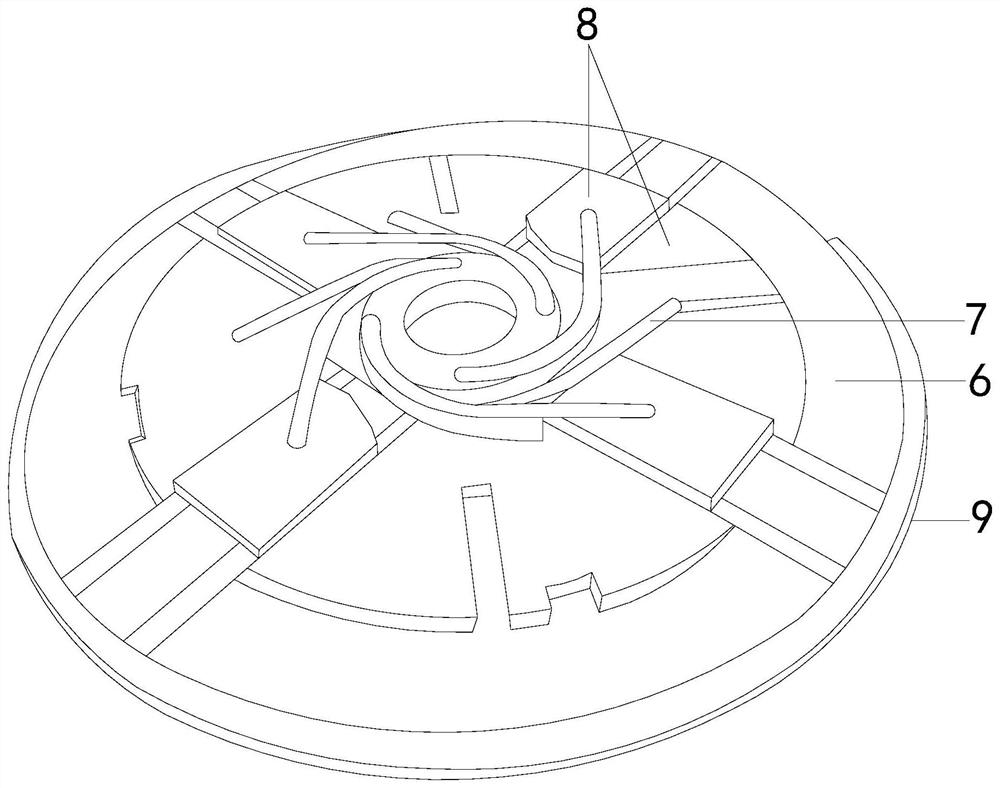

[0024] See figure 1 The present invention provides an inner wall cleaning apparatus of a venting hood venting conduit, including a cylindrical body 1, a cleaning plate mechanism 2, a collecting oil hole 3, the cylindrical body 1 bottom end connection cleaning disk mechanism 2, cleaning disk The surface of the mechanism 2 is provided with a gauge hole 3 and through the upper and lower ends of the structure, the cylindrical body 1 is the main structure of the upper half of the device, and the power component for carrying the equipment operation is efficiently running, while The construct of the entire device is connected to a connection, and the intensive hole 3 at the bottom of the cleaning plate mechanism 2 is an isometric distribution that exhibits an annular arrangement in its edge position, and the main means to make the collected oil can be discharged from this structure to a defined collection process. In the container, it is possible to avoid removing the drawback to remove ...

Embodiment 2

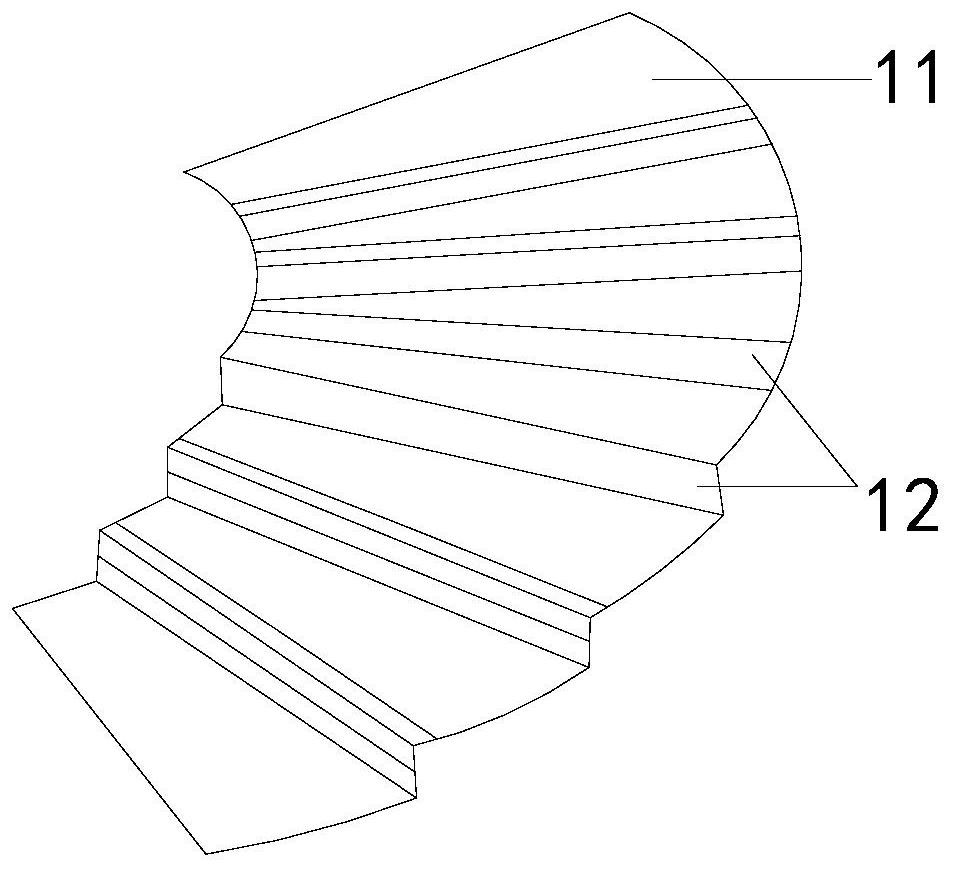

[0031] The second embodiment drawn in connection with the first embodiment, combined image 3 , Figure 4 versus Figure 5 The surface is equipped with a guide groove 12 on the surface of the cladding plate 11, and the push rod 15 side coupling strap 16, the position of the pipette 16 is in the position of the oleo 17, the ouli tube 17 Unicom hill 7, The tapered groove 20 is provided with an outer hose 21 and an outer hose 21 is provided and a stacked oil film 22 is active in its bottom position. The stacked oil film 22 is irregular film layer generates an internal cavity structure and promotes the structural change manufacturing. The lower suction will inhale the oil from the cone 20, and the guide groove 12 distributed by the step plate 11 is the drainage effect of the oil dresses using the height loss of the step plate 11, and the drainage can be moved toward the center position. Gathering, the oil scale oil absorbed by the straw 16 is directly dropped down to the oak tube 17 posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com