Mining rock drift heading machine

A roadheader and rock roadway technology, which is applied in the field of mine rock roadway roadheaders, can solve the problems that the bolter drilling machine is not perpendicular to the tunnel wall, the working mode affects the equipment's tunneling efficiency, and the bolt cannot play a safe anchoring role. , to achieve the effect of saving the time and work of artificial slag removal, improving space utilization and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

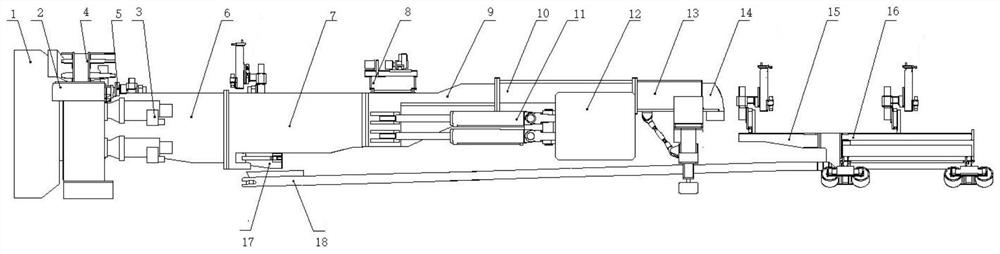

[0022] see figure 1 , the present invention provides a technical solution: a mining rock roadway boring machine, including a tunneling system, a tensioning propulsion system, a support system, a conveying system, a dust removal system, and a supporting system 16; The shield 2 and the main drive 3 are composed of shields 2 on the top, bottom, left, and right sides of the main drive 3, and the cutter head 1 is installed at the end of the main drive 3;

[0023] The tension propulsion system includes the front main beam 6, the drilling rig beam 7, the transition beam 9, the sliding beam 10, the rear support 13, the propulsion system 11 and the tension system 12, the active drive 3 is installed on the front main beam 6, and the front main beam 6 Connected with the drilling rig beam 7, the propulsion system 11 is installed on both sides of the transition beam 9 and the sliding beam 10, the tensioning system 12 is installed on the sliding beam 10, and one end of the propulsion system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com