Steel wire rope lubricating grease composition and preparation method thereof

A grease composition and wire rope technology, applied in the field of lubrication, can solve problems such as low dropping point, and achieve the effect of meeting the requirements of high temperature use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

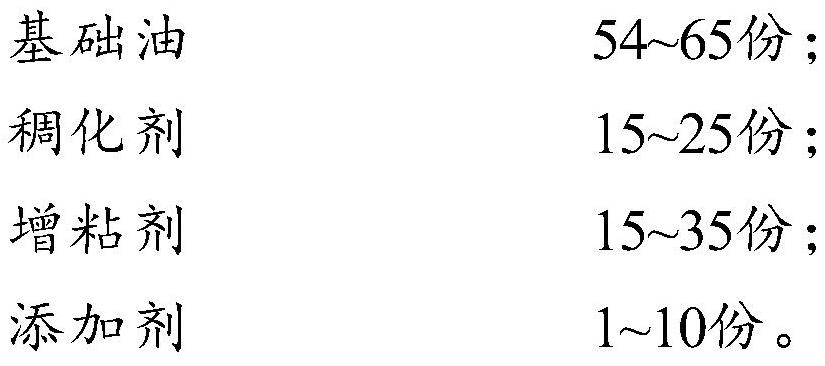

[0038] The present invention provides a kind of preparation method of the wire rope grease composition described in the above technical scheme, comprising:

[0039] The base oil, thickener, tackifier and additives are mixed to obtain a wire rope grease composition.

[0040] In the present invention, the mixing method preferably includes:

[0041] Mix base oil, thickener and tackifier to obtain a mixture;

[0042] The mixture and additives are mixed to obtain a wire rope grease composition.

[0043] In the present invention, the mixing temperature of the base oil, thickener and tackifier is preferably 130-150°C, more preferably 135-145°C, most preferably 140°C; the mixing time is preferably 1.5-2 hours , more preferably 1.6 to 1.8 hours.

[0044] In the present invention, the mixing temperature of the mixture and the additive is preferably 90-110°C, more preferably 95-105°C, most preferably 100°C.

[0045] The steel wire rope lubricating grease composition provided by the i...

Embodiment 1

[0048] In parts by weight, add 59 parts of mineral oil (Maoming Petrochemical), 18 parts of PE wax (Nanjing Tianshi) and 23 parts of tackifier (ethylene-propylene copolymer, Lubrizol), stir and heat up to 140°C, constant temperature for 1.5~2h; after the constant temperature is over, lower the temperature to about 100°C, add 1.5 parts of diphenylamine (Xilong Chemical Test), 2 parts of T202 (zinc dialkylthiophosphate, Xinxiang Ruifeng), 2 parts of T321 ( Sulfurized isobutylene, Shenyang Feida) 1.5 parts and barium petroleum sulfonate (Suzhou Sanli) 1.5 parts, to obtain steel wire rope surface grease.

[0049] According to the following method, the steel wire rope surface grease prepared by the embodiment of the present invention 1 is tested for performance, and the test results are as follows:

[0050]

[0051]

Embodiment 2

[0053] In parts by weight, add 59 parts of mineral oil (Maoming Petrochemical), 18 parts of OPE wax (Nanjing Tianshi) and 23 parts of tackifier (ethylene-propylene copolymer, Lubrizol), stir and heat up to 140 ℃, constant temperature 1.5 ~ 2h. After the constant temperature is over, lower the temperature to about 100°C, add 1.5 parts of diphenylamine (Xilong Chemical Test), 2 parts of T202 (zinc dialkylthiophosphate, Xinxiang Ruifeng), 1.5 parts of T321 (isobutylene sulfide, Shenyang Feida) 1.5 parts and 1.5 parts of barium petroleum sulfonate (Suzhou Sanli) to obtain steel wire rope surface grease.

[0054] According to the following method, the steel wire rope surface grease prepared by the embodiment of the present invention 2 is tested for performance, and the test results are as follows:

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com