Combined-type mist spray box

A spray box and combined technology, applied in the direction of spray device, liquid spray device, etc., can solve the problems of dripping water and poor thermal insulation effect, and achieve the effect of solving the problem of water dripping due to lax sealing, avoiding corrosion phenomenon and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described further in conjunction with accompanying drawing:

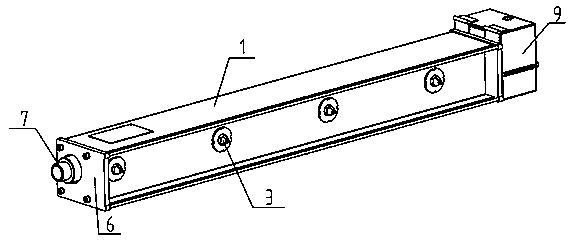

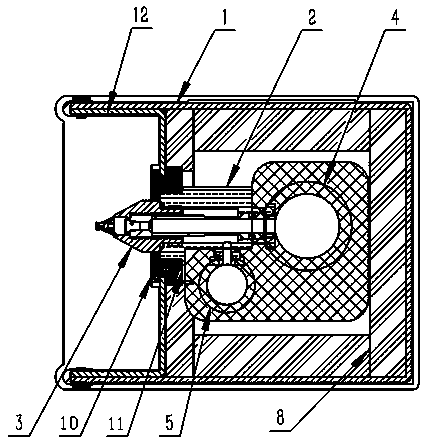

[0018] Such as figure 1 , 2 As shown, the spray box includes a strip-shaped box body 1 and a nozzle seat 2 formed by injection molding of metal (copper, stainless steel) and PPR plastic. , and the nozzle seat 2 is connected in series with the gas pipeline 4 and the water pipeline 5 by welding to avoid water leakage at the connection between the nozzle seat and the gas pipeline 4 and the water pipeline 5. The water pipeline 5 and the gas pipeline 4 are respectively connected to the The nozzle holder 2 is connected through, and the water pipeline 5 is located under the nozzle holder 2, which completely solves the problem of dripping water from the nozzle. The cover 11 is fixed to the box body 1 . End caps 6 are installed at both ends of the box body 1 respectively, and the end caps 6 have a supporting effect on the box body. On the left end cover of the box body 1, there is an outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com