Polyvinyl phosphorus antioxidant and preparation method and application thereof

A polyvinyl phosphorus and antioxidant technology, applied in the field of polyvinyl phosphorus antioxidants and their preparation, can solve the problems of low migration and extraction resistance, low molecular weight of antioxidants, poor thermal stability, etc., and achieve enhanced Migration resistance, high oxidation resistance, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040]The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0041] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

[0043] In a 50ml flask, 1g of polyethylene-vinyl acetate copolymer shown in formula IV (EVA, VA-19%, wherein x is 434, y+z is 33, and the copolymer is terminated with a methyl group) is dissolved in 20mL In tetrahydrofuran, heat in an oil bath at a temperature of 90°C, and magnetically stir to fully dissolve it. After the polyethylene-vinyl acetate copolymer shown in formula IV is completely dissolved, add 10 mL of sodium hydroxide-absolute ethanol solution to react for 2 hours. The product was precipitated with a large amount of absolute ethanol, filtered, washed repeatedly with absolute ethanol, and vacuum-dried for 12 hours to obtain the side chain hydroxyl-containing polyethylene represented by formula II.

[0044]

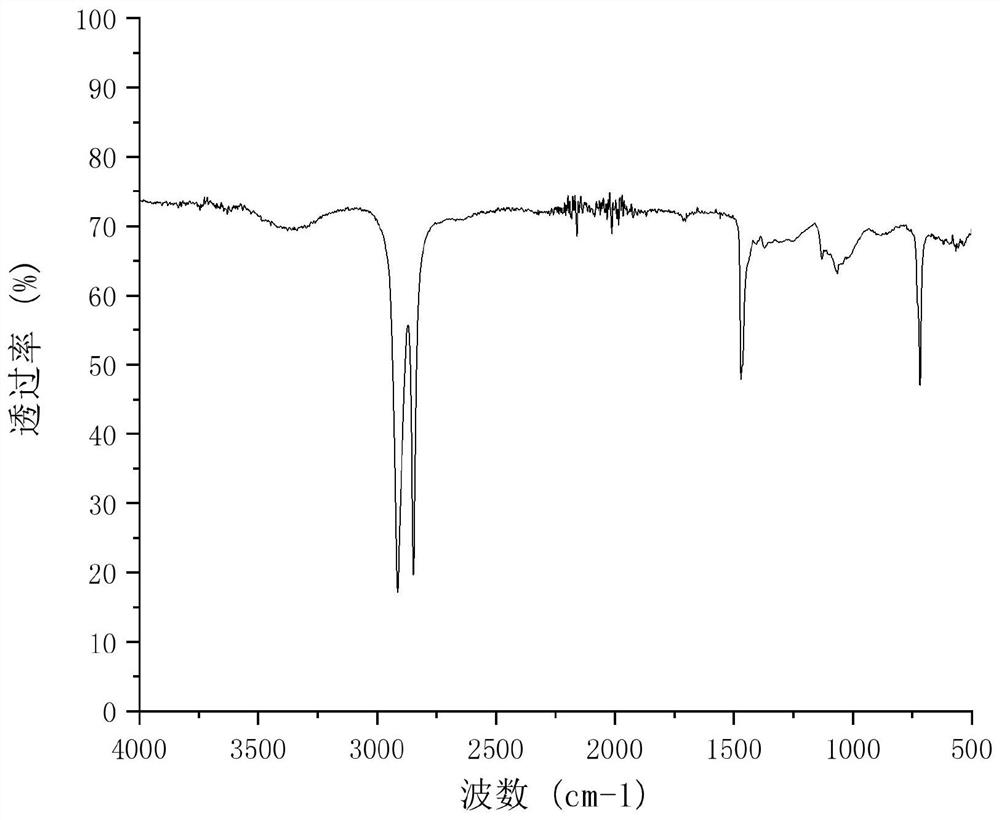

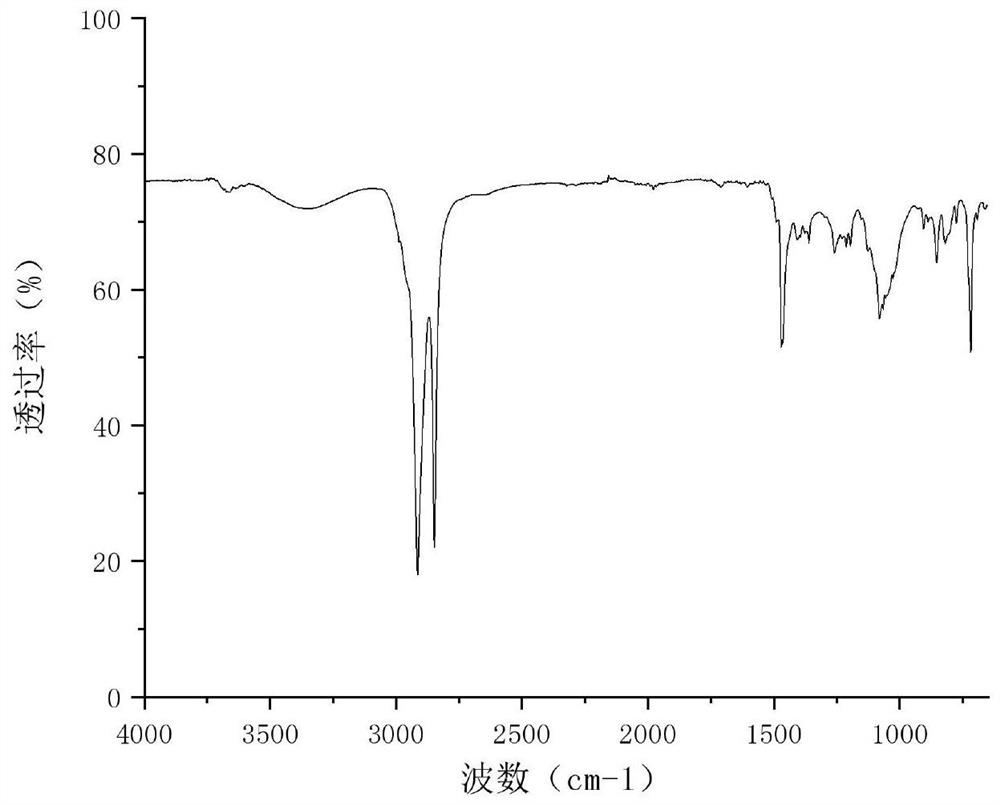

[0045] The FTIR characterization result of polyethylene-vinyl acetate copolymer shown in formula IV is as follows figure 1 Shown, the FTIR characterization result of the side chain containing hydroxyl group shown in formula II is as follows figure 2 As sh...

Embodiment 2

[0047] Add 100mL of xylene solution to a 250ml two-necked flask, and 25ml (about 0.05mol) of PCl 3 (2mol / L dissolved in dichloromethane, Energy Sea) and 20.6g (about 0.1mol) 2,4-di-tert-butylphenol were added, and then 0.02gMgCl 2 , Bubble nitrogen, react at 0-20°C for 1 hour, then raise the temperature to 60°C, react for 24h, remove unreacted substances and their solvent by rotary evaporation, and prepare the compound represented by the intermediate formula III. Get 2g intermediate and dissolve in xylene solution, join in the two-necked flask, add the side chain hydroxyl-containing polyethylene shown in the formula II that 0.5g above-mentioned embodiment 1 prepares, add 0.02gMgCl 2 , bubble nitrogen, heat up to 120°C, react for 4h, precipitate the product with absolute ethanol, filter, wash repeatedly with absolute ethanol, and vacuum-dry at 50°C for 12h to obtain a polyvinyl phosphorus-containing antioxidant (wherein the grafting rate is 16.7% (according to Figure 4 The i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com