Bagging and packaging machine for pillow interior

A packaging machine and pillow core technology, applied in packaging machines, packaging, transportation packaging, etc., can solve problems such as lack of system stability, increase cost, and occupy too much space, so as to save bagging volume and floor space , Improve the effect of discharging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

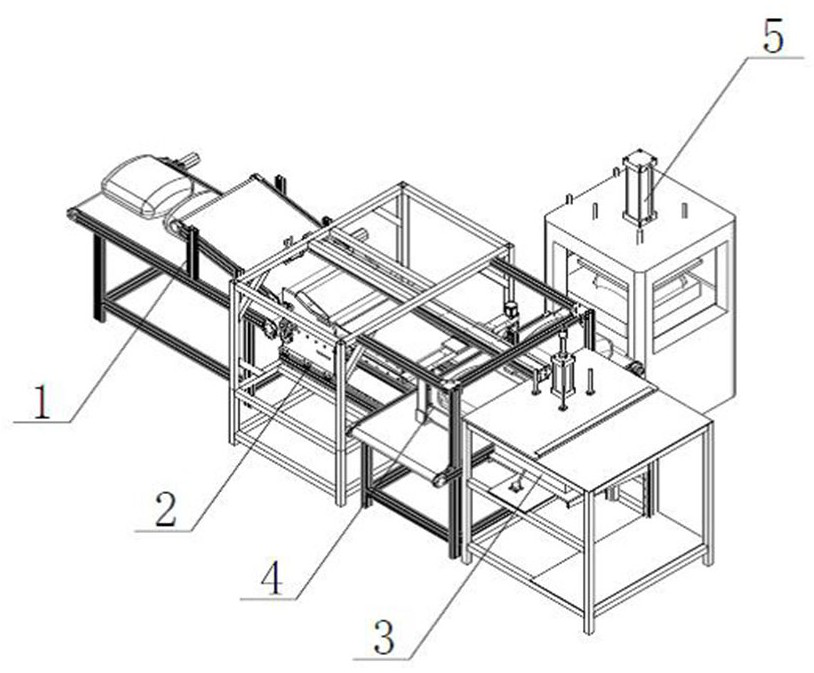

[0043] Example: such as figure 1 Shown, a kind of pillow bag packing machine, comprises feeding device 1, compressing device 2, bag opening device 3, bagging device 4, discharging device and sealing bag device 5; Wherein feeding device 1, compressing device 2 , the bag opening device 3 and the bagging device 4 are arranged in a straight line, but the bagging device 4 is located between the compression device 2 and the bag opening device 3, and the discharge device is located below the bagging device 4, and the bag sealing device 5 is located at the side of the discharge device.

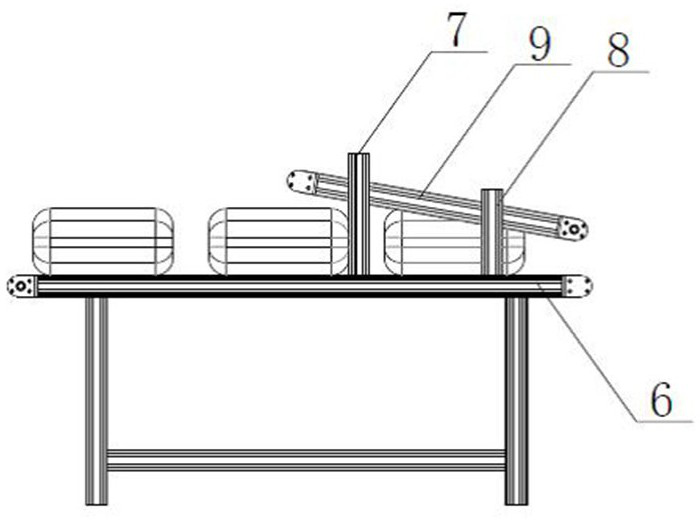

[0044] Such as figure 2 As shown, the feeding device 1 includes a first conveyor 6; a pair of high columns 7 and a pair of low columns 8 are sequentially arranged on the end of the first conveyor 6 along its conveying direction, and the height of the high columns 7 is higher than that of the low columns. The height of the column 8, two high columns 7 and two low columns 8 jointly support a second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com