Power distribution switch welding current diagnosis system and using method thereof

A welding current and diagnostic system technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of low automation and low intelligence, achieve high automation, high intelligence, and improve diagnosis effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

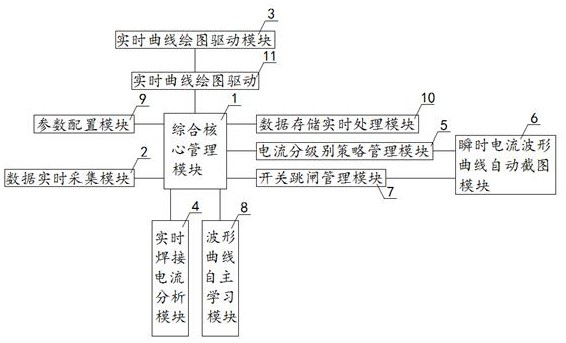

[0077] see figure 1 , a power distribution switch welding current diagnosis system, including a comprehensive core management module 1, a real-time data acquisition module 2, a real-time curve drawing drive module 3, a real-time welding current analysis module 4 and a current classification strategy management module 5; The core management module 1 is connected with the data real-time acquisition module 2, the real-time curve drawing driving module 3, the real-time welding current analysis module 4 and the current classification strategy management module 5, and the current classification strategy management module 5 is automatically connected with the instantaneous current waveform curve. The screenshot module 6 is connected; the integrated core management module 1 is used to control the data real-time acquisition module 2, the real-time curve drawing driver module 3, the real-time welding current analysis module 4 and the current classification strategy management module 5 mo...

Embodiment 2

[0085] Basic content is the same as embodiment 1, the difference is:

[0086] see figure 1 , the welding current diagnostic system also includes a switch trip management module 7, the switch trip management module 7 is connected to the integrated core management module 1, the instantaneous current waveform curve automatic screenshot module 6, and the switch trip management module 7 is used for Capture, detect and identify the flashing momentary action; the welding current diagnostic system also includes a waveform curve self-learning module 8, and the waveform curve self-learning module 8 is connected with the integrated core management module 1, and the waveform curve self-learning module 8 It is used to compare and analyze real-time waveform curves and normal waveform curves; the waveform curve self-learning module 8 is provided with an expert library for comparing and analyzing normal waveform curves; the welding current diagnostic system also includes a parameter configura...

Embodiment 3

[0088] Basic content is the same as embodiment 1, the difference is:

[0089] see figure 1 , the instantaneous value of the welding current data is the instantaneous value of the ABC three-phase current, the multi-level current limit value is divided into high-level H, middle-level M and low-level L, the instantaneous value of the three-phase current and the multi-level current limit value Corresponding; the standard in the screenshot retention step refers to that the instantaneous value of any one of phase A, B, and C of the three-phase current reaches or exceeds the standard value of advanced H.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com