Multi-pass rolling type sheet flexible flanging forming method

A multi-pass, flanging technology, applied in the field of sheet metal parts manufacturing, can solve the problem of high precision of insert installation, achieve the effect of simple and feasible method, and improve forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

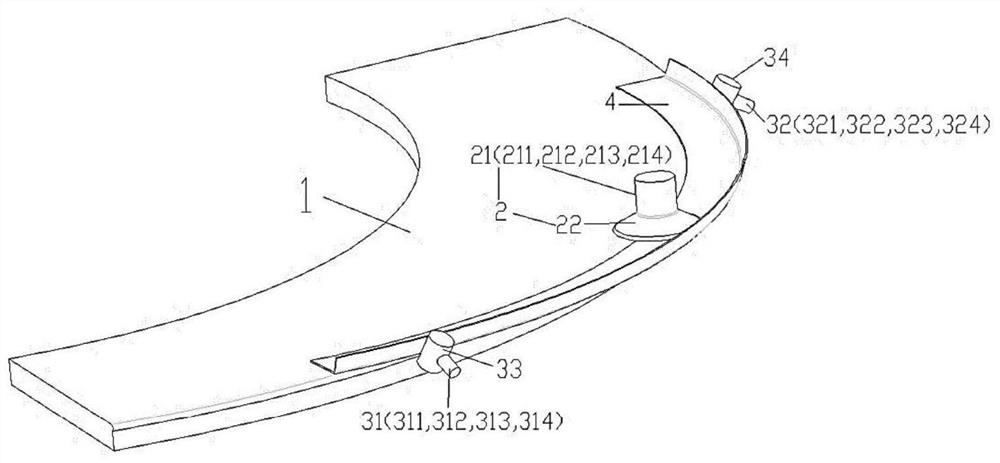

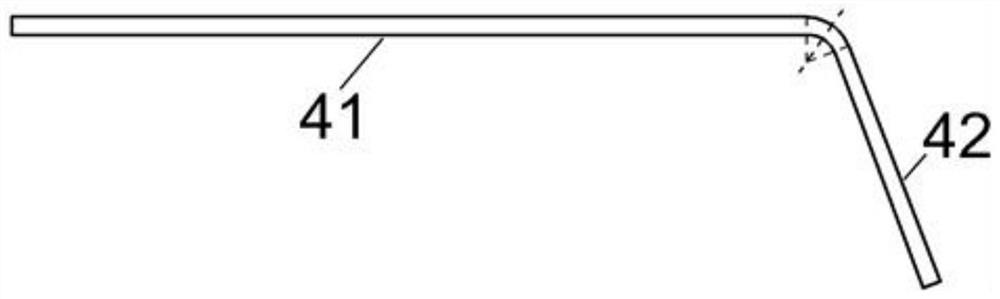

[0015] like figure 1 As shown, this embodiment relates to a multi-pass rolling type flexible flanging forming system, including: a flanging table 1, a pressing wheel mechanism 2, a flanging roller mechanism 3, an information receiving module, and an information comparison calculation modules, motion control modules, including: figure 2 The shown target flanging piece 4 is located on the flanging table 1, the pressing wheel mechanism 2 and the flanging roller mechanism 3 are respectively located on the inner and outer sides of the target flanging piece 4, and the information receiving module transmits the pressing wheel mechanism and the turning wheel mechanism. The theoretical position information of the side roller mechanism, the information comparison calculation module obtains the local adjustment displacement according to the position information, and the motion control module adjusts the displacement information according to the local area. posture, to achieve multi-pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com