Coffee bean baking system capable of controlling caffeine content and baking method thereof

A technology of coffee beans and caffeine, applied in the field of baking, can solve the problems of increased bitterness, long cooling time, easy to get angry, etc., and achieve the effect of medium and moderate acidity, short cooling time, and reduce bitterness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, so that those skilled in the art can understand the present invention in detail, but the present invention is not limited in any way. Any transformation or improvement made according to the technical inspiration of the present invention belongs to the protection scope of the present invention.

[0025] The present invention will be further elaborated below in conjunction with the accompanying drawings.

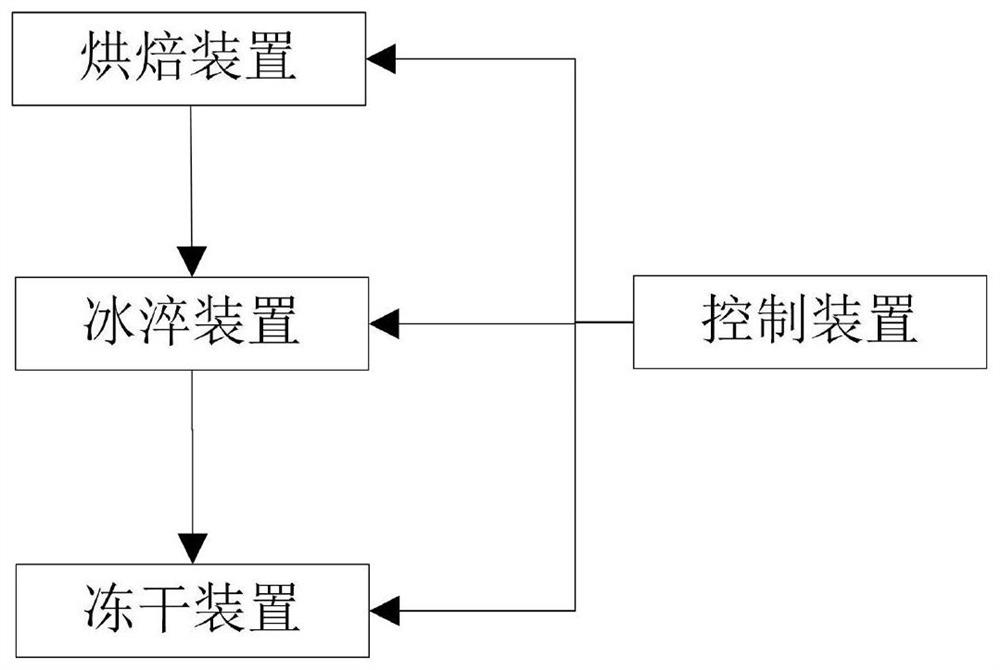

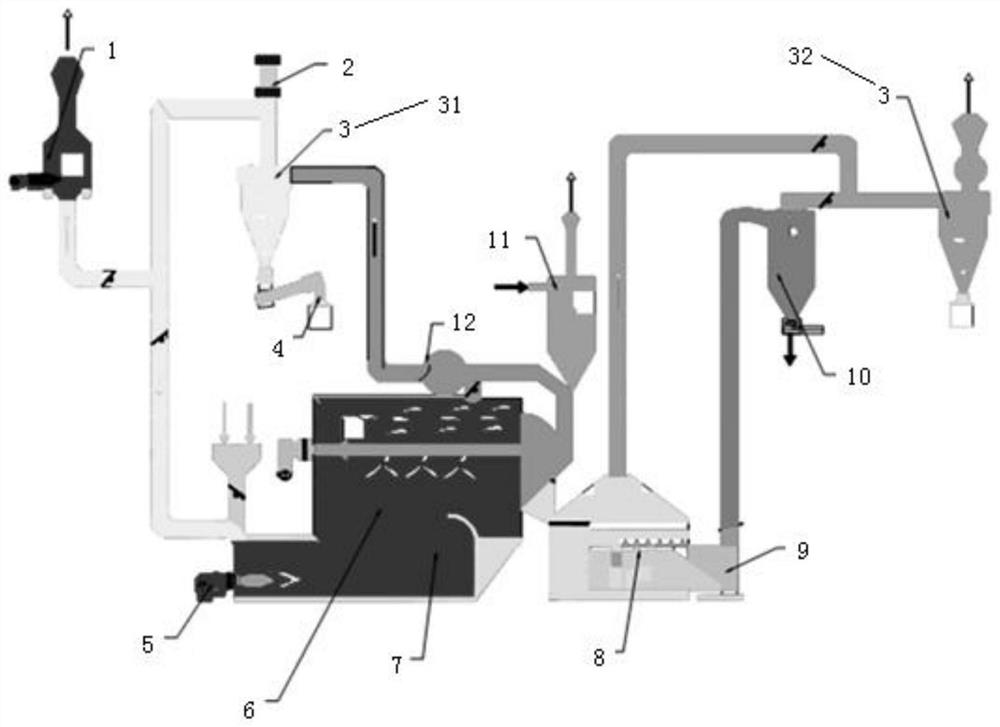

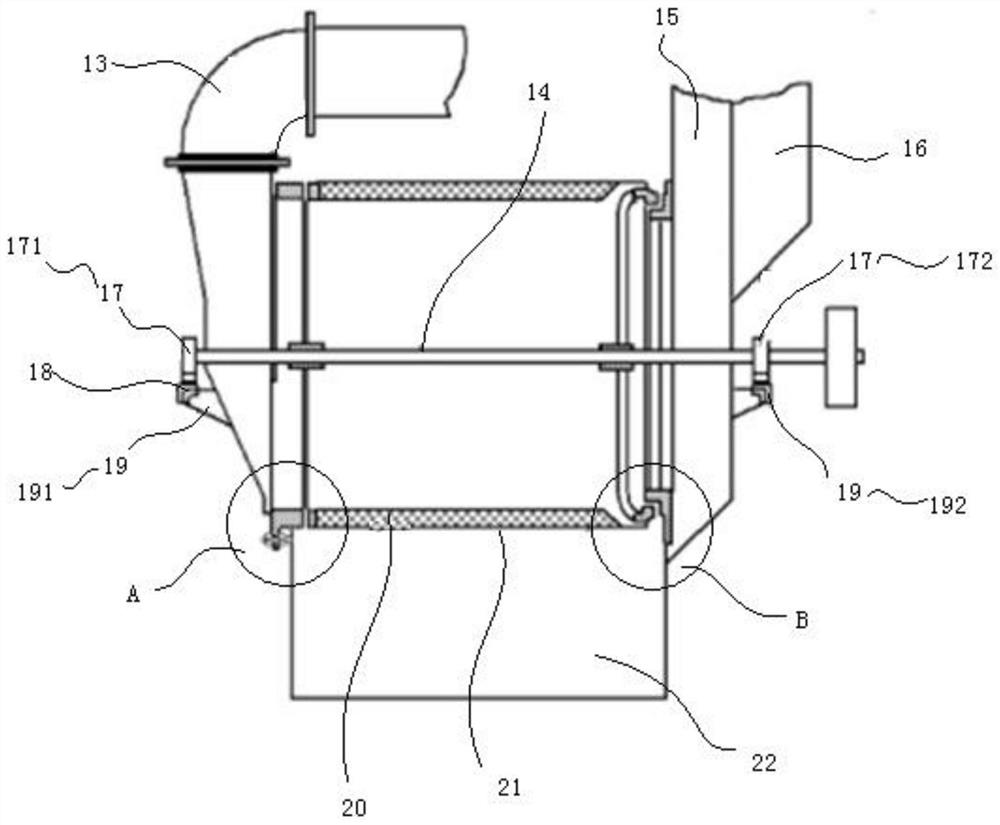

[0026] Such as Figure 1-10 As shown, the present invention provides a coffee bean roasting system capable of controlling the caffeine content. The system specifically includes: a roasting device for roasting coffee beans in real time; an ice-quenching device; a freeze-drying device for drying coffee beans after ice-quenching in real time; and a control device for controlling the operations of the roasting device, the ice-quenching device and the freeze-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com