Steel wire and hot-rolled wire material

A technology of steel wire and spherical carbide, applied in the field of steel wire and hot-rolled wire rod, can solve the problems of metal mold wear, processing cracks and damage of formed parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0197] Hereinafter, the steel wire of the present invention will be described more specifically. However, these examples do not limit the steel wires of the present invention.

[0198] [Made of steel wire]

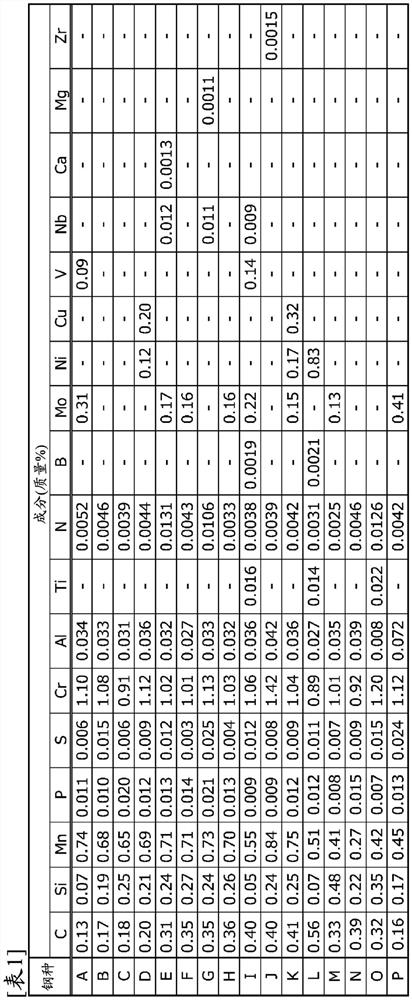

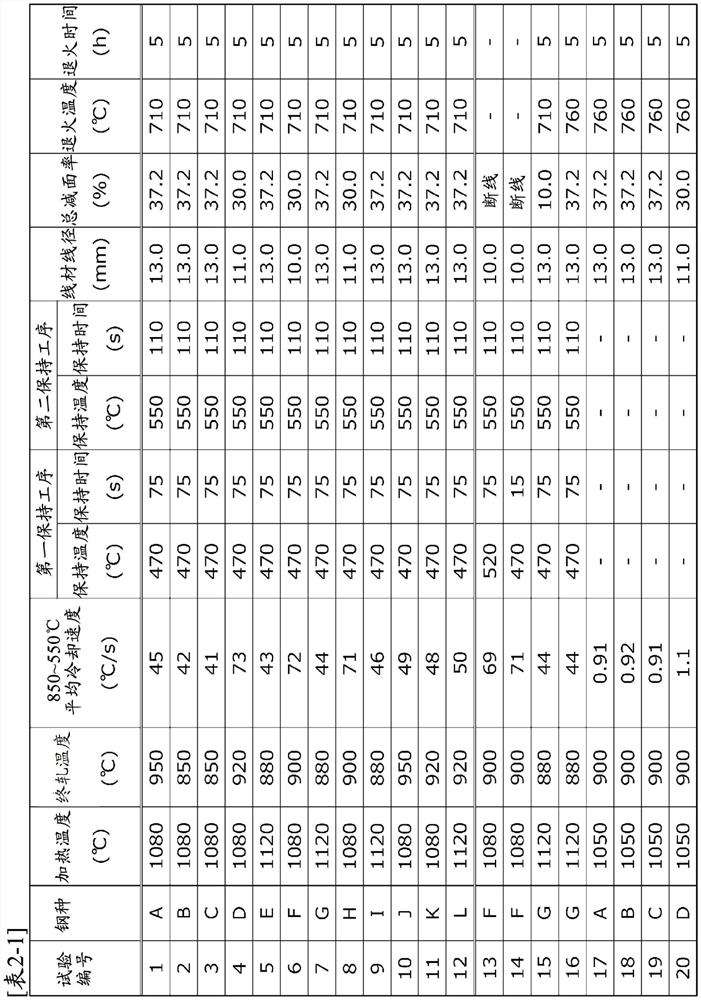

[0199] A steel sheet having a steel species A to P, which is composed of the components shown in Table 1, and the steel wires are fabricated as follows from Tables 2-1 to T 3-2, which will be described below. It should be noted that the part indicated in "-" in Table 1 is not intentionally added to the elements in the column.

[0200] Further, in Tables 2-1 to T 3, the underscore portion indicates that it is not included in the scope of the present invention or is not included in the optional preferred range.

[0201]

[0202] Specifically, the steel wires of the test numbers 1 to 16, 32 to 36, 41 shown in Tables 2-1 to T 3-4 are manufactured as follows.

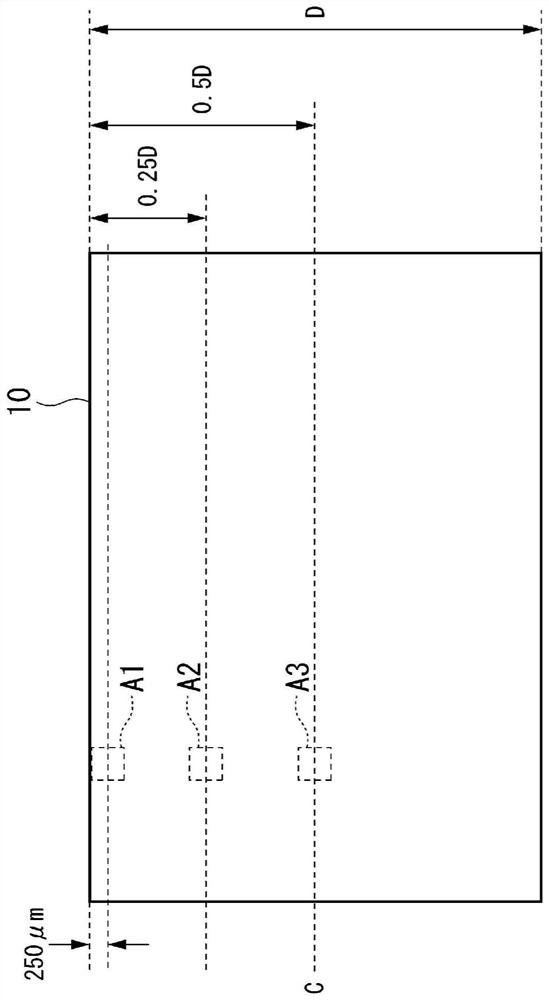

[0203]First, the steel sheet after heating, hot rolling, resulting in a ring wire, immersed in the molten salt bath is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com