Molding die apparatus for resin molded products, molding apparatus, molding system, and manufacturing method for molded products

A manufacturing method and mold technology, which are applied in the field of mold devices, molding devices, molding processing systems, and molding products for resin molded products, can solve problems such as no limitation, and achieve the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

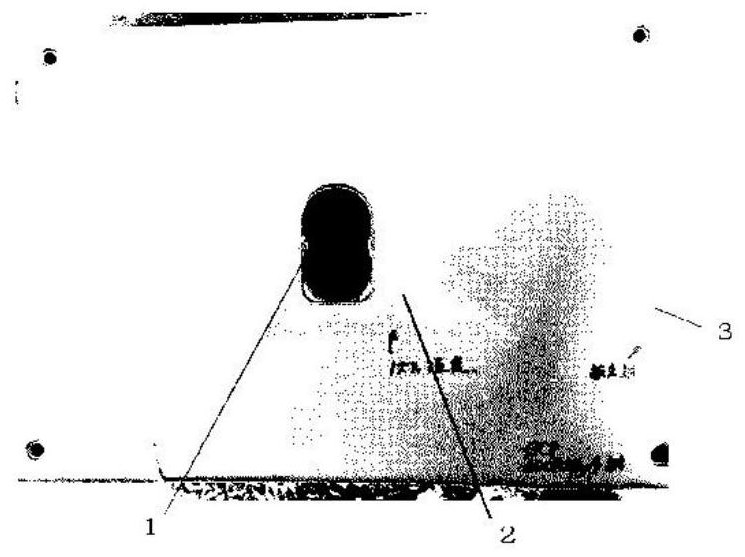

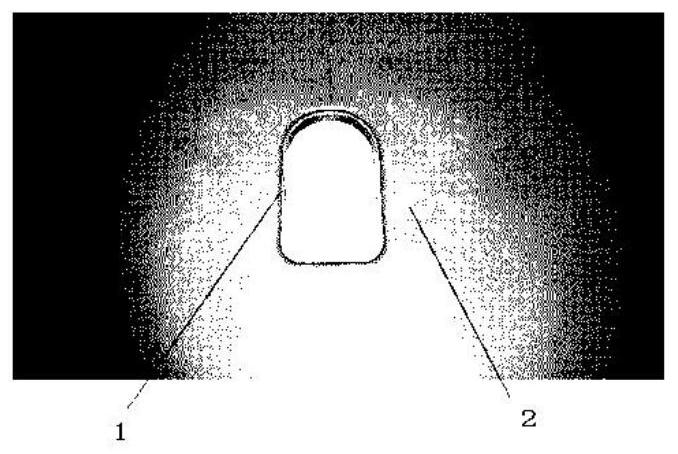

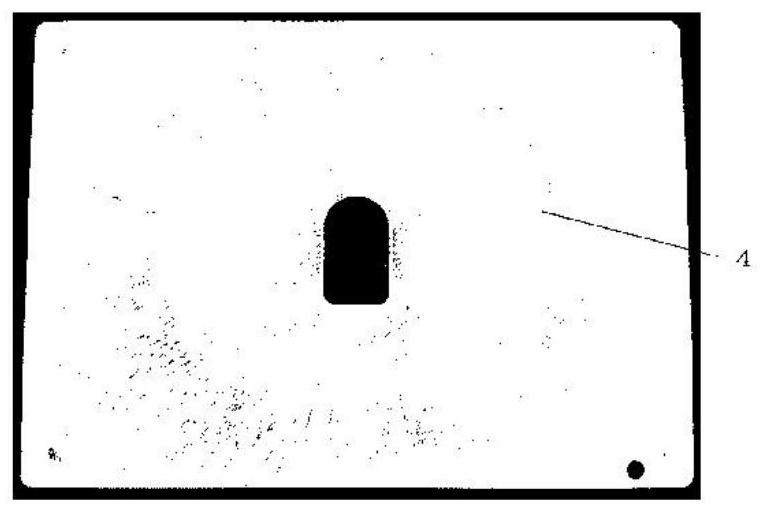

Image

Examples

Embodiment Construction

[0377] (definition of terms)

[0378] First, the terms used in the present invention are defined.

[0379] (insufficient, below, above)

[0380] "Insufficient" does not include the numerical values shown below. "Below" includes the numerical values shown after. "Above" includes numerical values shown below. For example, less than PH7 does not contain 7, and its solution is not neutral (PH=7) but acidic. Below PH7 contains 7, so it is neutral and acidic.

[0381] (Available products, etc.)

[0382] Products to which the present invention can be applied are not particularly limited in terms of material, shape, application, etc., as long as they are resin molded products produced by injection molding, injection molding, block molding, or the like. Styrenic resins, polymer alloys and polymer blends containing styrenic resins are mainly used in OA, home appliances, game machines, and the like. In vehicles, olefinic resins or polymer alloys or blended polymers containin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com