Method for determining the operational conditions of a method for high-repetition rate femtosecond laser ablation for a given material and method for laser welding between parts of a determined material

A femtosecond laser and laser ablation technology, used in laser welding equipment, material thermal analysis, material analysis, etc., can solve problems such as difficulty in determining operating parameters and disputes over exact properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The invention relates in particular to the field of bursts having a duration of femtoseconds (less than picoseconds) and an intra-burst repetition frequency of GHz.

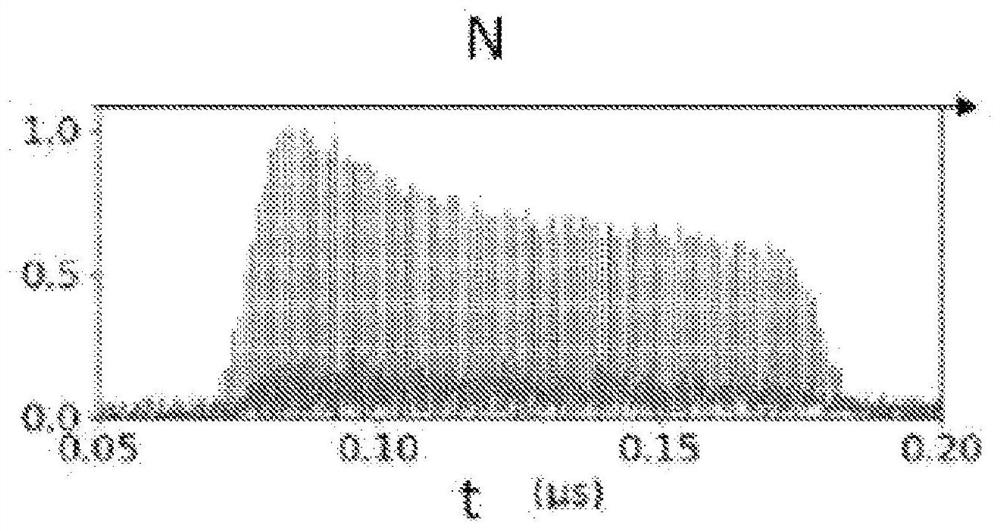

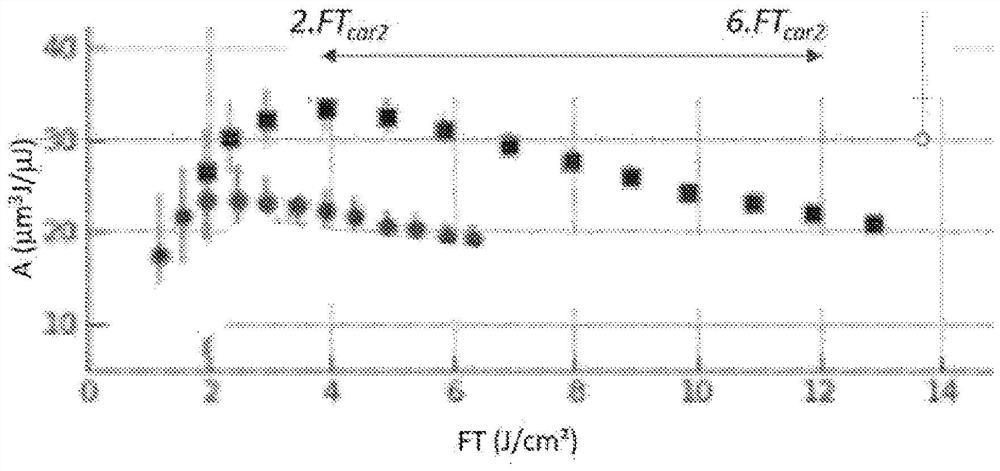

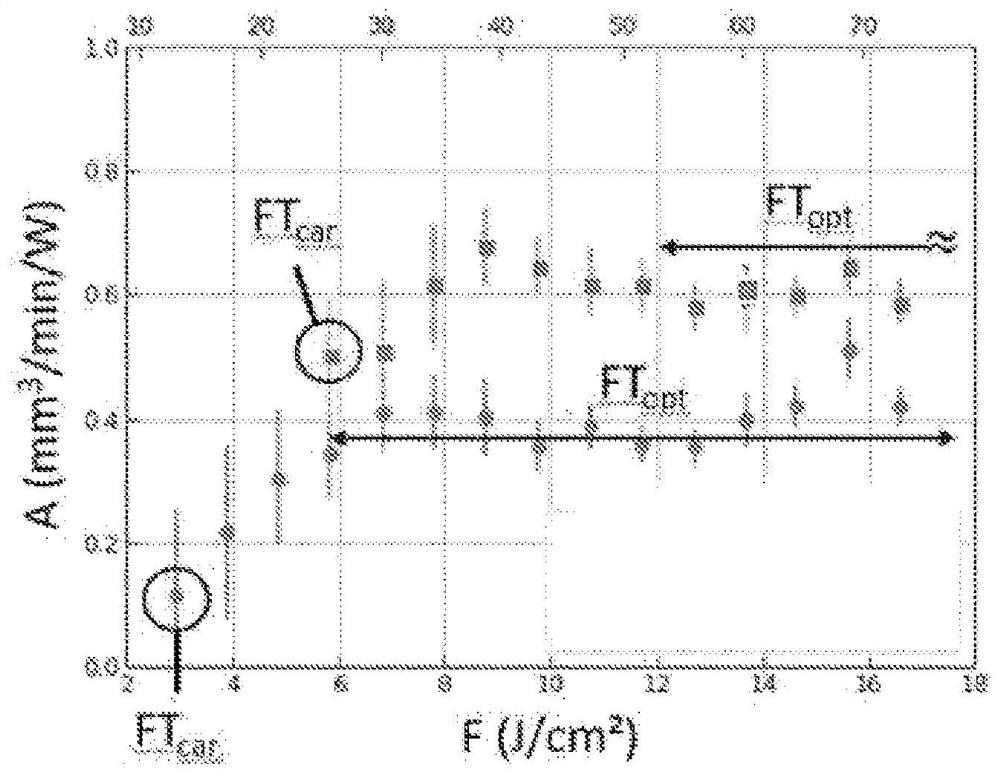

[0053] The present disclosure proposes a method for determining the operating conditions of a laser ablation method for a given material, comprising the step of determining a set of parameters for a burst repetition frequency f of the order of GHz, the set of parameters comprising an integer number of bursts of laser pulses N pulses, and a fluence per pulse F of the burst. The burst total fluence FT seen from the material is equal to the product N.F. The repetition rate C of the bursts is another parameter of the laser source used.

[0054] The integer N pulses of the laser pulse burst is at least greater than or equal to 10, specifically, the number N of pulses is between 10 and 800. In some applications, the number N of femtosecond pulses in a burst is greater than 20 or 50, between 100 and 800, or bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com