Support-beam-type MEMS (micro electromechanical systems) fluid thermal conductivity and thermal diffusion coefficient sensor and preparation and testing methods thereof

A technology of thermal diffusivity and supporting beams, which is applied in the field of supporting beam MEMS fluid thermal conductivity and thermal diffusivity sensors and their preparation and testing, can solve the problems of increasing measurement errors and the influence of insulating layer films, etc., and achieve temperature rise small size, improve experimental accuracy, and simplify the test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

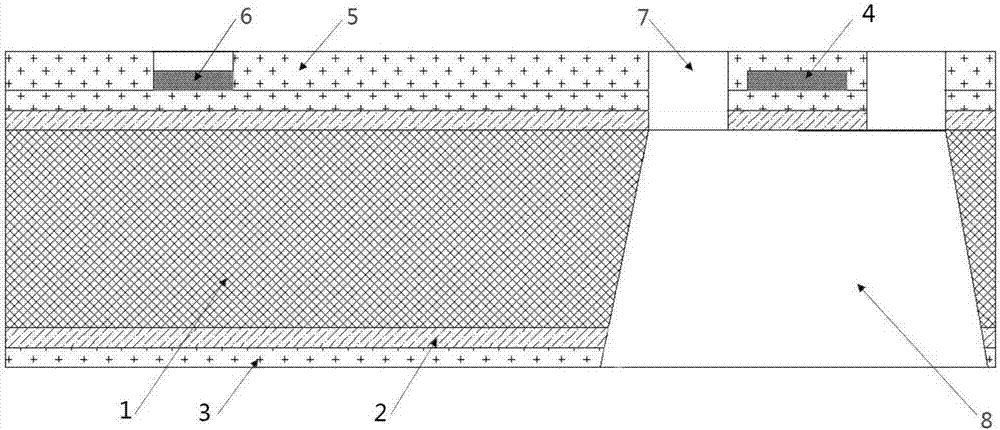

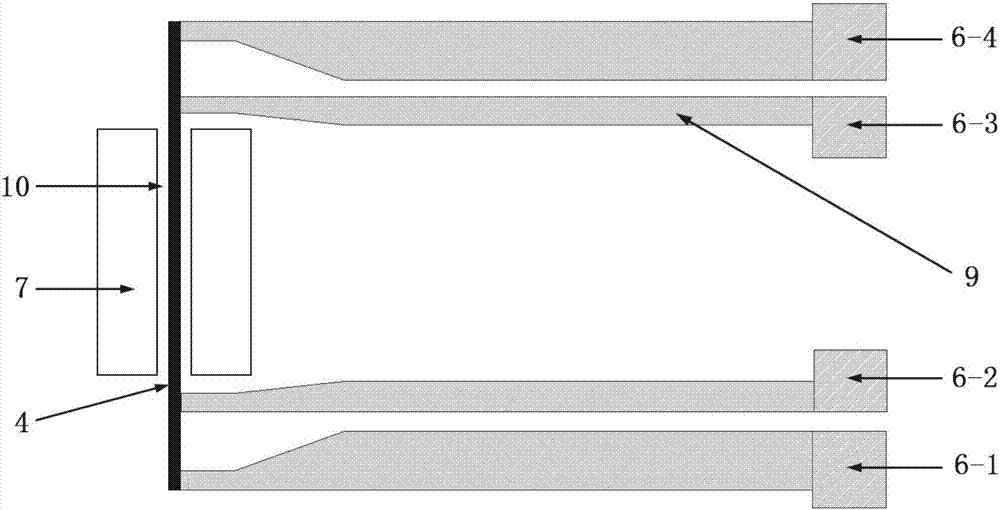

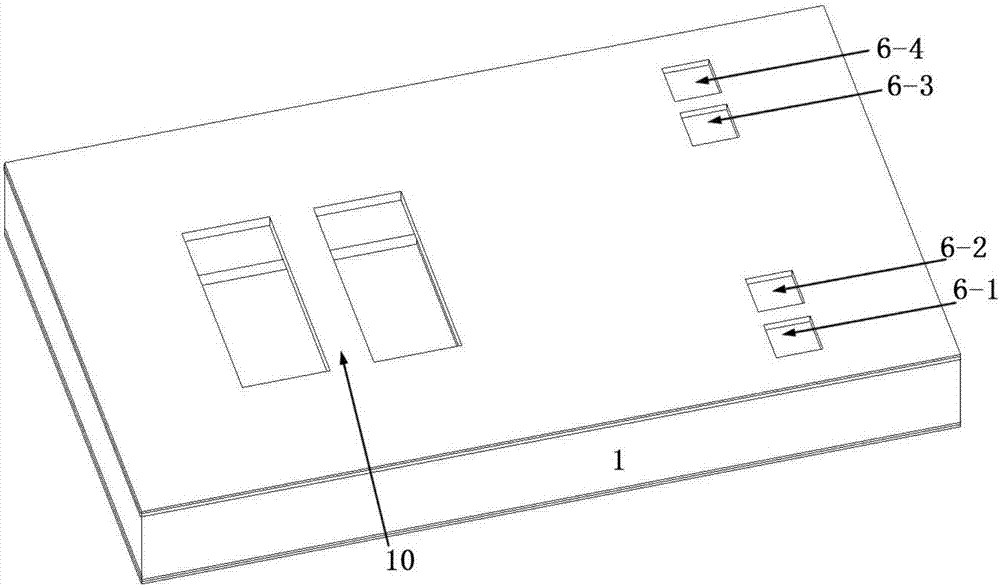

[0052] refer to figure 1 , the supporting beam type MEMS fluid thermal conductivity and thermal diffusivity sensor disclosed by the present invention comprises a substrate 1, including a substrate 1, a composite support film layer is provided on the upper and lower surfaces of the substrate 1, and the composite support film layer on the upper surface of the substrate 1 A heater 4 and a pad 6 are arranged on the supporting film layer, and the heater 4 and the pad 6 are connected through a lead 9; an insulating layer film 5 is also provided above the composite supporting film layer on the upper surface of the substrate 1, and the insulating layer film 5 covers heater 4 and pad 6;

[0053] In the thickness direction of the composite support film layer and the insulating layer film 5 on both sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com