Film longitudinal thermal diffusion coefficient measuring system and method based on medium detector

A technology of thermal diffusivity and measurement system, which is applied in the field of thin film longitudinal thermal diffusivity measurement system based on dielectric detector, can solve the problems of inaccurate and impossible measurement of thin film thermal diffusivity, and achieve shortened test cycle and small sample damage , the effect of flexible test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

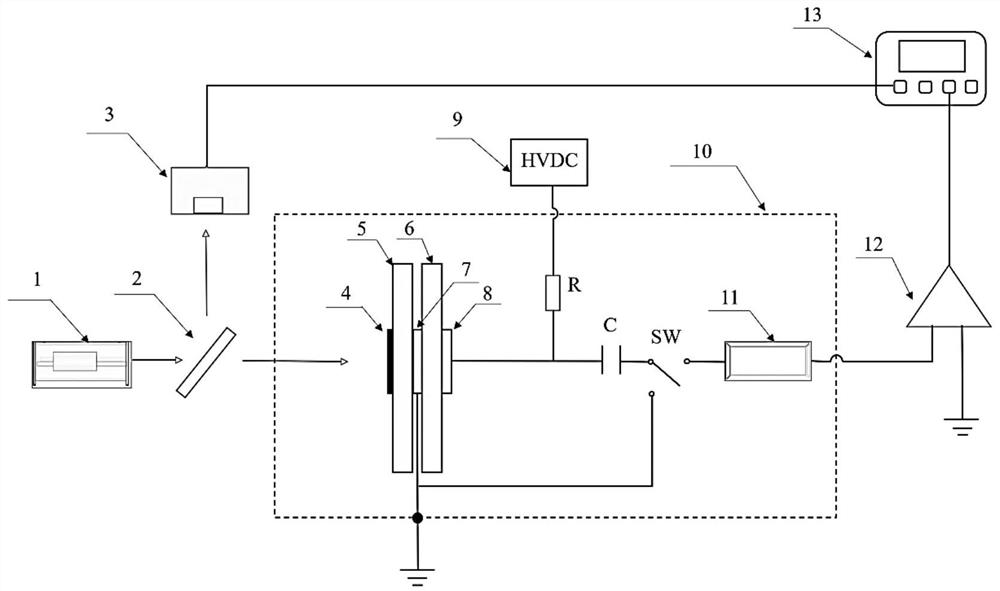

[0056] This embodiment provides a film longitudinal thermal diffusivity measurement system based on a thin film dielectric detector, which is used to measure the longitudinal thermal diffusivity of the film 5 to be measured. The film longitudinal thermal diffusivity measurement system includes a pulse light source 1, a beam splitter 2, a front Set current amplifier 12, oscilloscope 13, photoelectric trigger device and medium detector;

[0057] The dielectric detector includes a grounded metal electrode 7, a dielectric film 6 and a pressurized metal electrode 8 arranged in sequence. One side of the measured film 5 is provided with a laser target 4, and the other side is used to connect to the grounded metal electrode 7. The grounded metal electrode 7 is grounded, and the pressurized metal electrode 8 is connected to a DC high-voltage power supply 9, and the pressurized metal electrode 8 is also connected to the input terminal of the pre-current amplifier 12, and the ground termi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal diffusivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com