Mini quantum dot LED and manufacturing method thereof

A technology of quantum dots and quantum dot layers, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing blue light excitation effect and blue light utilization rate, complex manufacturing process of quantum dot fluorescent film, and high manufacturing cost of quantum dot fluorescent film , to achieve the effect of reducing processing and adding processes, reducing thickness and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The purpose of the present invention can be achieved through the following technical solutions:

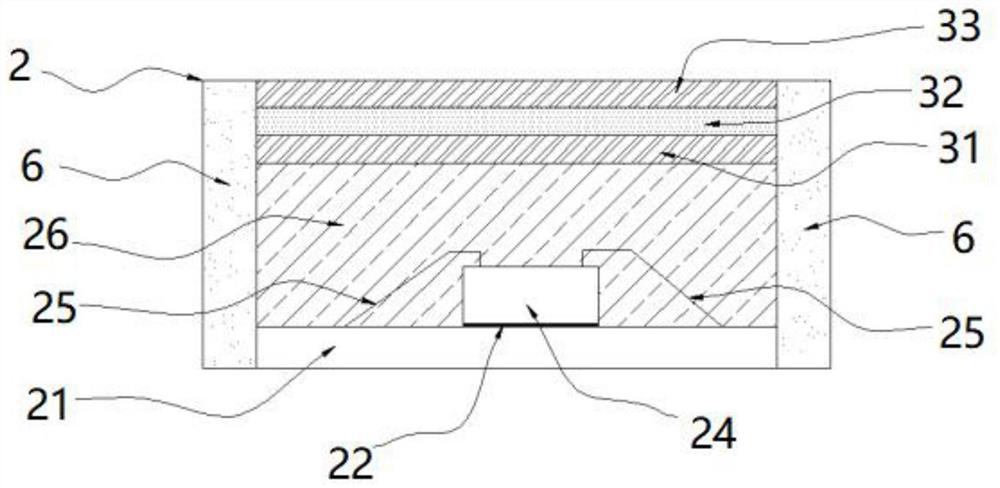

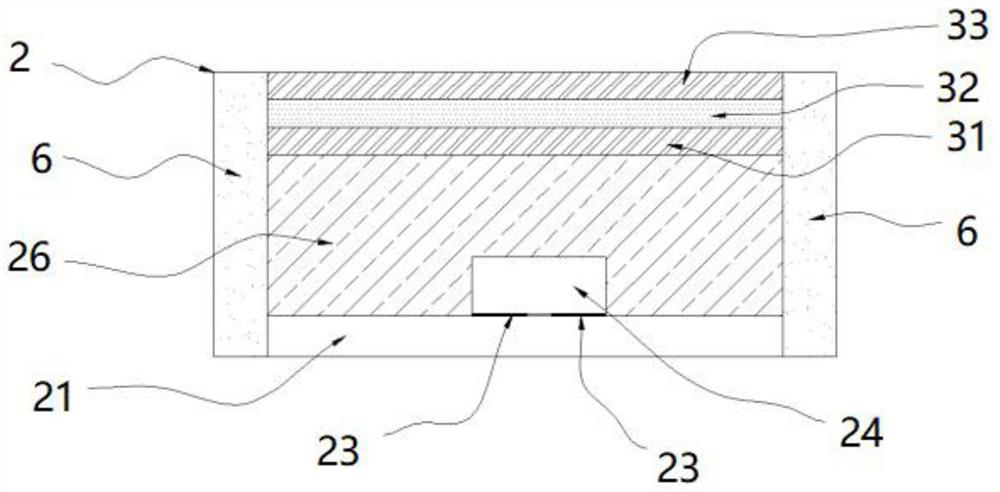

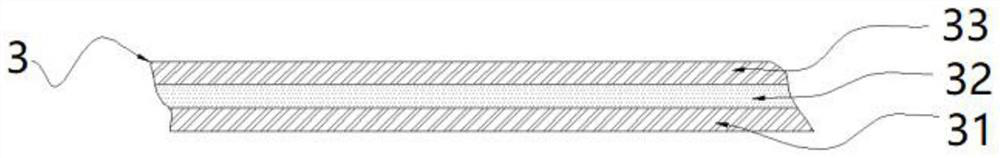

[0051] A Mini quantum dot LED, see Figure 1~3 , including LED lamp beads 2, quantum dot fluorescent film 3, and side walls;

[0052] The inner top layer of the LED lamp bead 2 is provided with a quantum dot fluorescent film 3, and the quantum dot fluorescent film 3 contains a quantum dot layer 32; the LED lamp bead 2 and the quantum dot fluorescent film 3 are integrated to directly emit white light, and the No gap, reducing the thickness of the combination of LED lamp beads and quantum dot fluorescent film, which is conducive to the development of ultra-thin backlight modules; using LED lamp bead-level quantum dot fluorescent film3, compared with the traditional full-layer quantum dot fluorescent film solution , greatly reducing the amount of quantum dot fluorescent film used; the top layer of the LED lamp bead 2 is directly covered with quantum dot fluorescent film 3, re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com